Silicone oil removing equipment

A technology of equipment and silicone oil, which is applied in the field of silicone oil removal equipment, can solve the problems of excess silicone oil collection, uneven silicone oil volume, etc., and achieve the effects of reducing manufacturing costs, increasing efficiency, and uniform oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

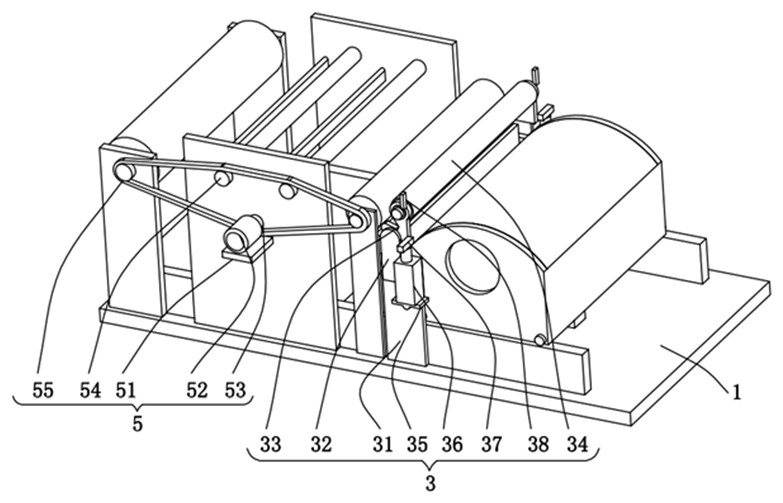

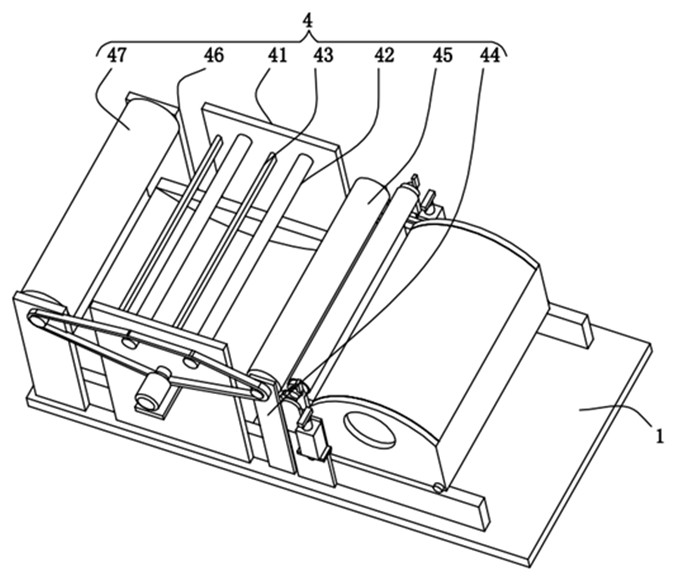

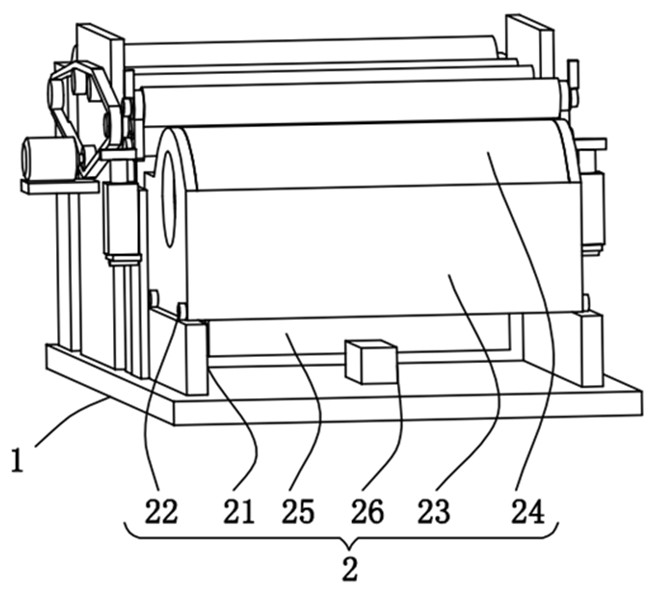

[0029] Please refer to figure 1 , figure 2 with image 3 ,in, figure 1 A schematic structural view of the first embodiment of the silicon oil removal equipment provided by the present invention; figure 2 for figure 1 The structural schematic diagram of the air knife assembly shown in the top view; image 3 for figure 1 The schematic diagram of the structure of the side of the bottom plate is shown. Silicone oil removal equipment, including: bottom plate 1;

[0030] The collection assembly 2, the bottom of the collection assembly 2 is arranged on the right side of the top of the bottom plate 1;

[0031] The air knife assembly 3, the bottom of the air knife assembly 3 is arranged on the top of the bottom plate 1;

[0032] The scraper assembly 4, the bottom of the scraper assembly 4 is arranged on the top of the bottom plate 1;

[0033] The power assembly 5 , the back of the power assembly 5 is arranged on the front of the scraper assembly 4 .

[0034] The collection ...

no. 2 example

[0046] Please refer to Figure 4 ,in, Figure 4 It is a schematic structural diagram of the second embodiment of the silicon oil removal equipment provided by the present invention. Based on the silicon oil removal device provided in the first embodiment of the present application, the second embodiment of the present application proposes another silicon oil removal device. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0047] Specifically, the difference between the silicone oil removal equipment provided in the second embodiment of the present application is that an adjustment assembly 6 is provided on the back of the air knife assembly 3 .

[0048] The adjustment assembly 6 includes two adjustment plates 61, the fronts of the two adjustment plates 61 pass through the air knife assembly 3 and extend the outside of the air knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com