On-line self-circulation cleaning device for cooling conduit

A technology for cooling ducts and cleaning devices, applied in the directions of cleaning hollow objects, cleaning methods and utensils, filtration and separation, etc., can solve problems such as abnormal torque failure, difficult disassembly and cleaning of cooling ducts, and poor cooling effect of rotating hubs, so as to ensure normal operation. work, ensure cleanliness, improve the effectiveness of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

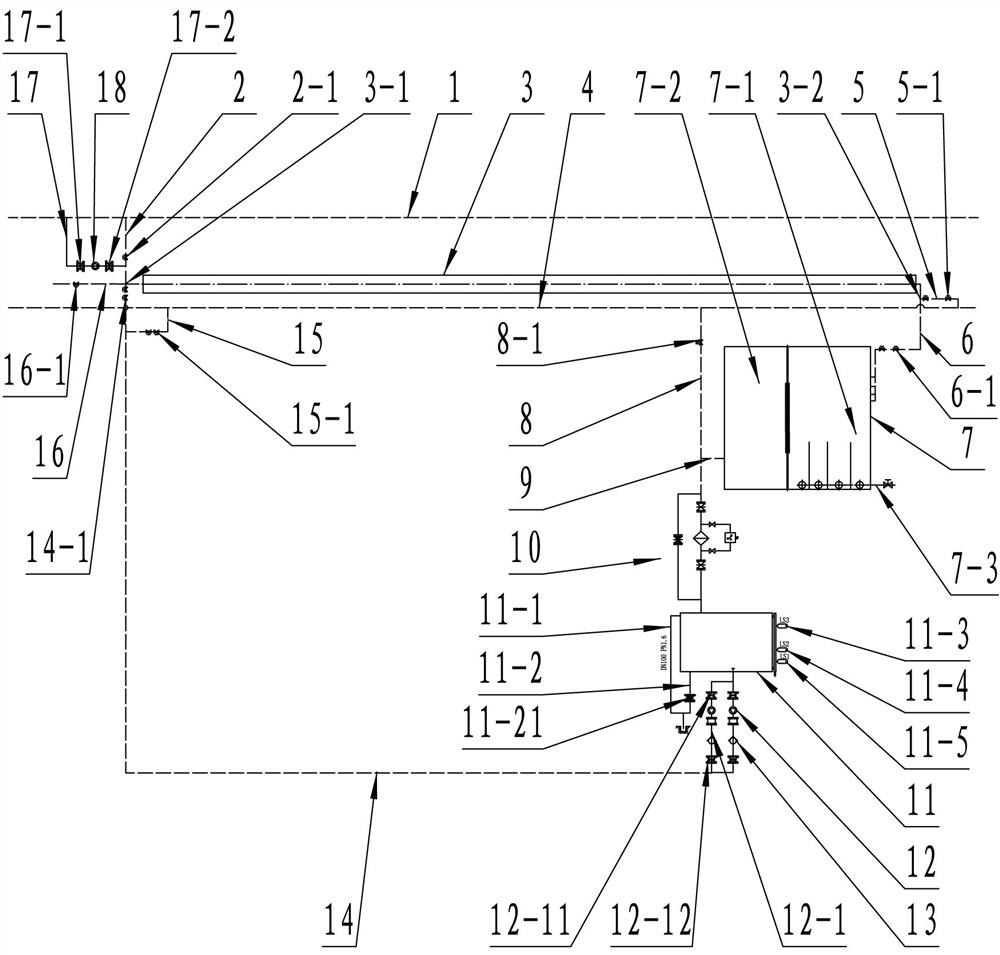

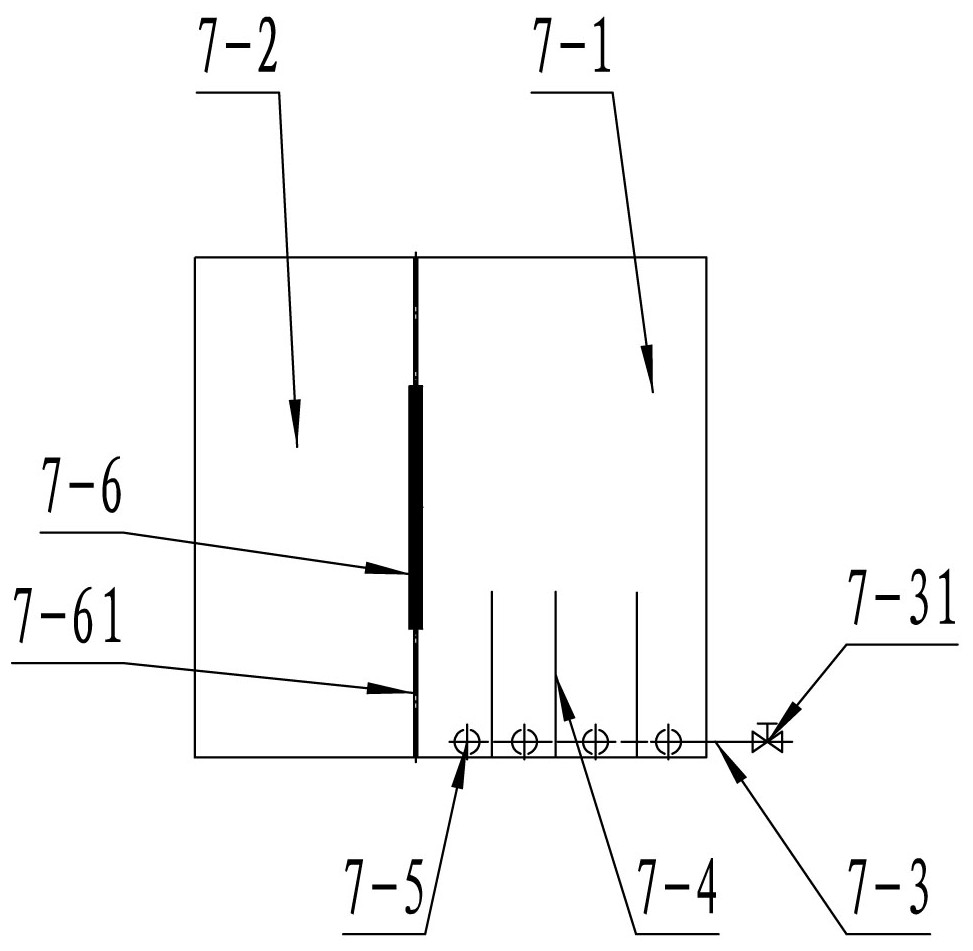

[0029] figure 1 The shown cooling conduit online self-circulation cleaning device mainly includes a primary water tank 7, a secondary water tank 11, a circulation pump 12, connecting pipelines and a valve body. The water outlet 3-2 and the cooling conduit 3 form a circulation loop of cleaning liquid. Such as figure 2As shown, the first-level water tank 7 is provided with a return chamber 7-1, a clean water chamber 7-2 and a filter plate 7-6, and the filter plate 7-6 is fixed in the first-level water tank 7 by a mounting plate 7-61. The water chamber 7-1 and the clean water chamber 7-2 are only communicated through the filter plate 7-6, and the cooling water return port 3-2 of the return water chamber 7-1 and the cooling conduit 3 is communicated through the circulation return pipe 6, and the circulation return pipe 6 A circulating water return valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com