Molded case circuit breaker

A molded case circuit breaker and casing technology, which is applied in the low-voltage electrical field and can solve problems such as increased volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of this application will be described in detail below with examples, so as to fully understand and implement the implementation process of how to apply technical means to solve technical problems and achieve technical effects in this application.

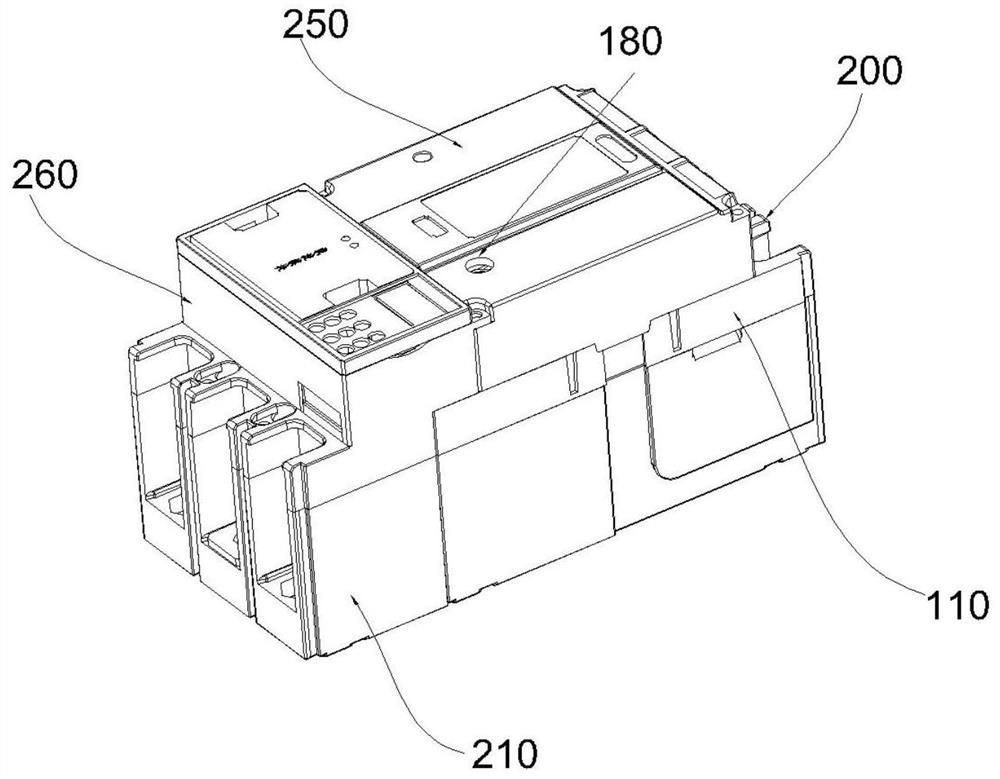

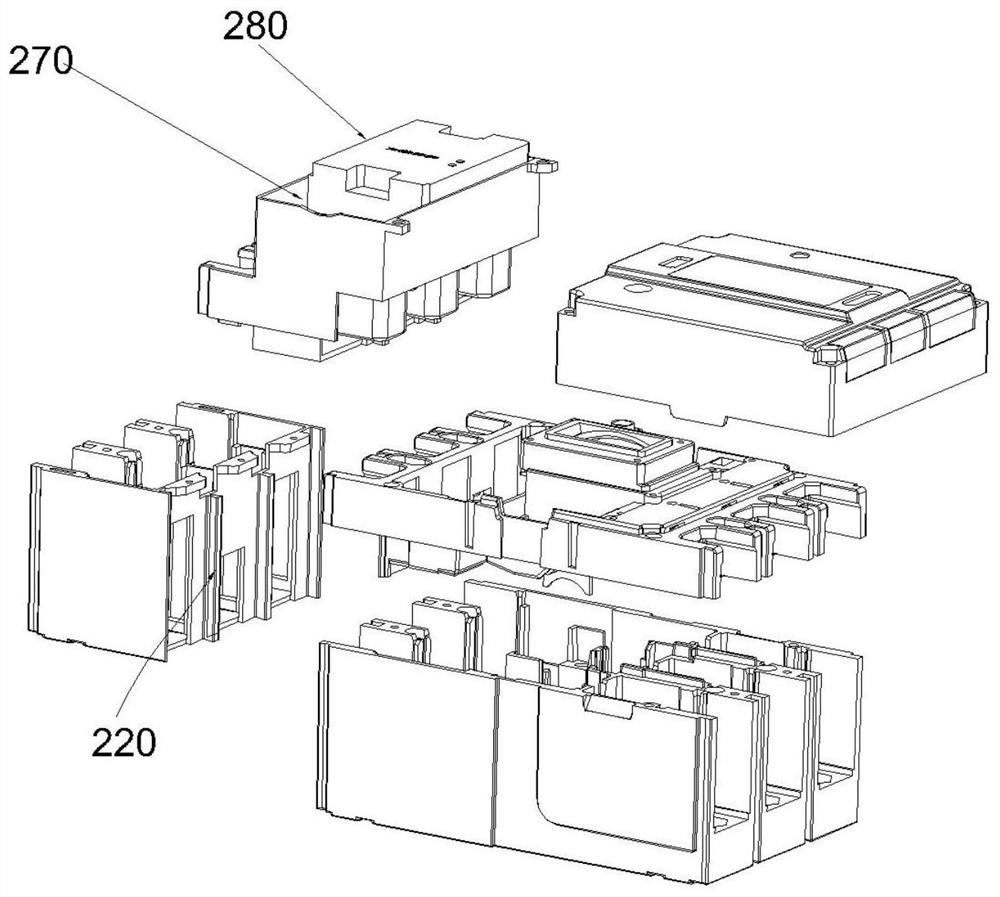

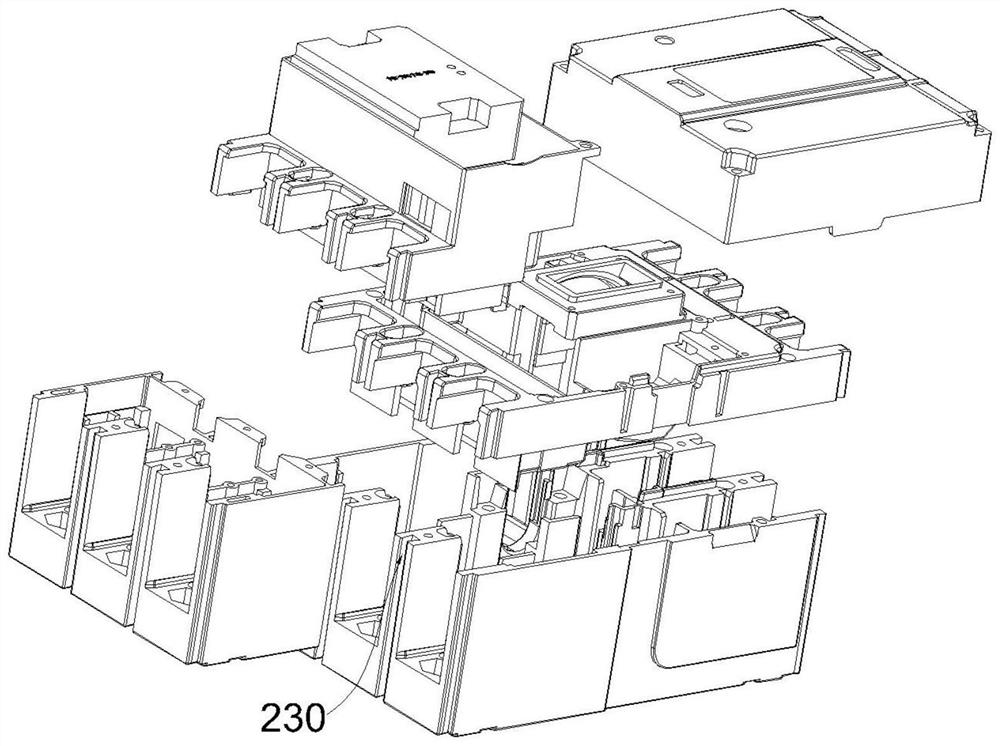

[0026] Such as Figure 1-9 As mentioned above, the present invention is a molded case circuit breaker, which includes a housing, and the housing is provided with a reclosing mechanism and a reduction box mechanism linked with the reclosing mechanism. Set the gear 10, the external gear 10 is provided with a linkage wheel 30, the linkage wheel 30 is connected with a connecting rod 20, the other end of the connecting rod 20 is connected with the handle 40, when the handle 40 is divided once Closing operation, the linkage wheel 30 rotates 360°.

[0027] A limit column 50 is formed on the external gear 10, and the linkage wheel 30 has a first arc-shaped notch 60 and a second arc-shaped notch 70, and the limit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com