Novel milling cutter

A new type of milling technology, used in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of single specifications, poor dimensional consistency, and increased manufacturing costs of processed products, and achieve high processing efficiency, good dimensional consistency, and manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

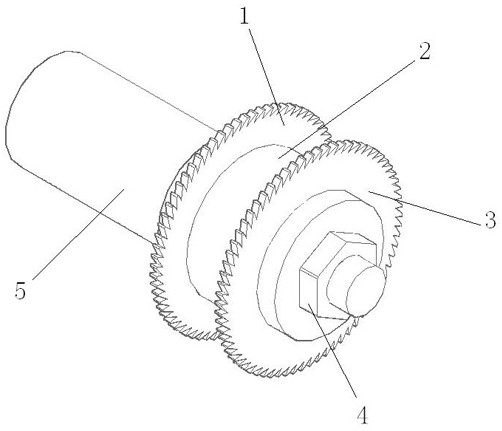

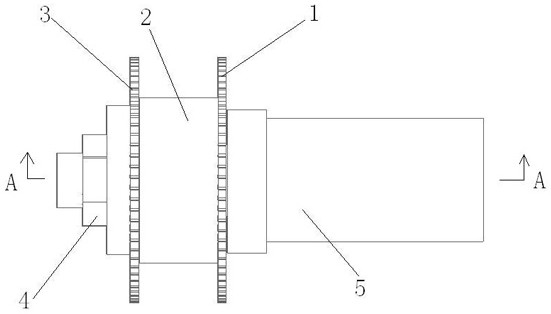

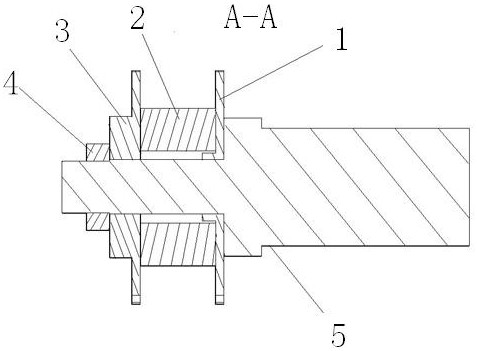

[0016] The specific implementation, structure, features and effects of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0017] A novel milling device of the present invention is characterized in that the outer surface of the shaft 5 is respectively covered with the milling blade A1, the gasket 2, and the milling blade B3, and the locking nut 4 is tightened to connect.

[0018] The set of milling inserts A1 and B3 are serrated.

[0019] The gasket 2 can be replaced with different specifications and thicknesses.

[0020] When using, see Figure 5 , the milling nut 6 is fixed, the shaft 5 is installed on the milling machine, the upper and lower milling blades A1 and B3 mill the two opposite sides of the hexagonal milling nut 6 at the same time, three times to complete the hexagonal plane of the milling nut 6, when the specifications and sizes of the milling nut 6 are different , the width is differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com