Milling machine mechanism special for inner surface of annular workpiece

A ring-shaped workpiece and inner surface technology, which is applied in the field of milling machines, can solve problems such as low machining accuracy, inability to accurately complete positioning operations, time-consuming and labor-intensive inner surfaces of ring-shaped workpieces, and achieve the effects of increased production efficiency, improved positioning accuracy, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

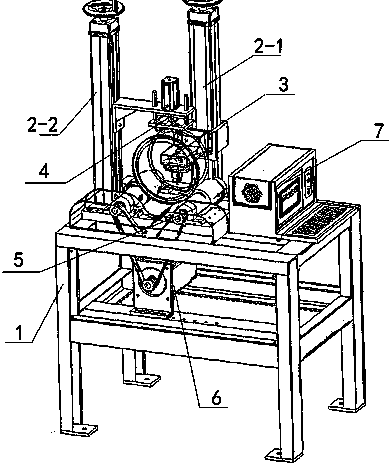

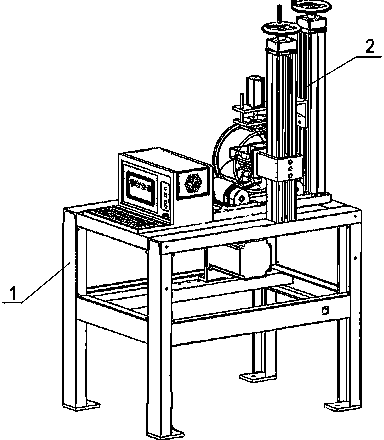

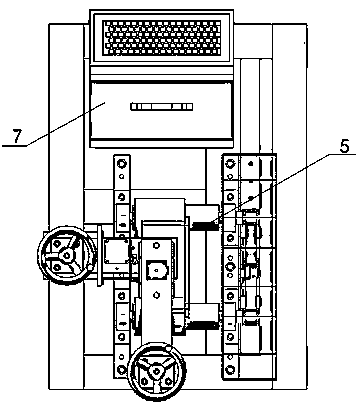

[0027] Embodiment 1: This embodiment discloses a milling machine mechanism dedicated to the inner surface of a ring-shaped workpiece. The milling machine mechanism includes a frame 1, a column 2 is arranged on the frame, and a milling cutter assembly 3 and a pressing assembly 4 are arranged on the column 2. , wherein the column 2 includes a first column 2-1 and a second column 2-2, slide rails are provided on the first column 2-1 and the second column 2-2, and the milling cutter assembly 3 is slidably arranged on the second column On a column 2-1, the pressing assembly 4 is slidably arranged on the second column 2-2, and the milling cutter assembly 3 includes a plate set 3-1 matched with the slide rail of the first column, and the plate set 3-1 The front end is fixed with a receiving plate 3-2, and the receiving plate 3-2 is fixedly connected with a milling cutter control box 3-3. The milling cutter control box 3-3 is provided with an electrical control component, and the milli...

Embodiment 2

[0041] Embodiment 2: This embodiment discloses the method of using the milling machine mechanism on the inner surface of the annular workpiece in Embodiment 1. Specifically, the steps of using the milling machine mechanism are as follows:

[0042] A. Operate the driving device on the first column, so that the milling cutter assembly moves down to a suitable distance along the column, place the annular workpiece to be operated between the two rolling wheels through the milling cutter assembly, and adjust the position.

[0043] B. Operate the driving device on the second column to make the pressing assembly move down along the column. When the rolling wheel is at an appropriate distance from the upper surface of the workpiece, the pressing motor is turned on. With the cooperation of the sliding column, the pressing motor stretches. The rod drives the bearing frame to move downward, and the two rolling wheels on the bearing frame are pressed on the upper surface of the workpiece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com