Vertical motor single-lifting-point turning-over auxiliary device and turning-over process

An auxiliary device, vertical motor technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of unusable car cranes, damage to the motor body, damage to the landing part, etc., to solve the problem of turning over the motor, low cost, Efficient and cost effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

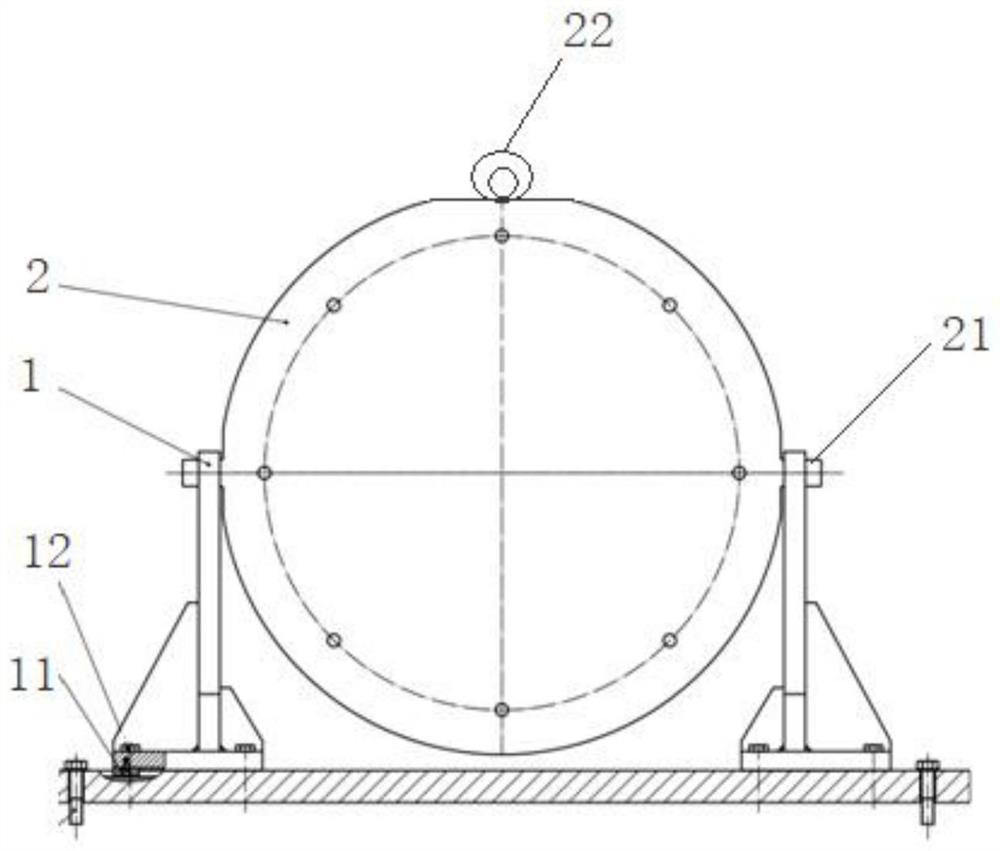

[0025] see figure 1 , a vertical motor single suspension point turn over auxiliary device of the present invention, including two brackets 1 and auxiliary support disc 2.

[0026] The bracket 1 is fixed on the base by fixing bolts 11 . The bracket 1 has a trapezoidal structure, and the bracket 1 is provided with a triangular reinforcing rib structure 12 perpendicular to the plane of the trapezoidal structure, and a clamping groove is opened on the top of the bracket.

[0027] The auxiliary support disc 2 is provided with a motor connection screw hole, and a set of center-symmetric support heads 21 are arranged on the outer peripheral surface of the auxiliary support disc, and the support heads 21 are matched with the clamping grooves. The auxiliary support disc is provided with a hanging point 22.

[0028] Take the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com