Single-hook Turning Method for Axial Flow Paddle Turbine Runner

A water turbine and runner technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of not being able to meet the safety requirements of hoisting, high requirements for the selection of power station bridge cranes, and increased investment costs of power stations, and achieve the elimination of instantaneous Impulse risk, avoiding hoisting risk, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

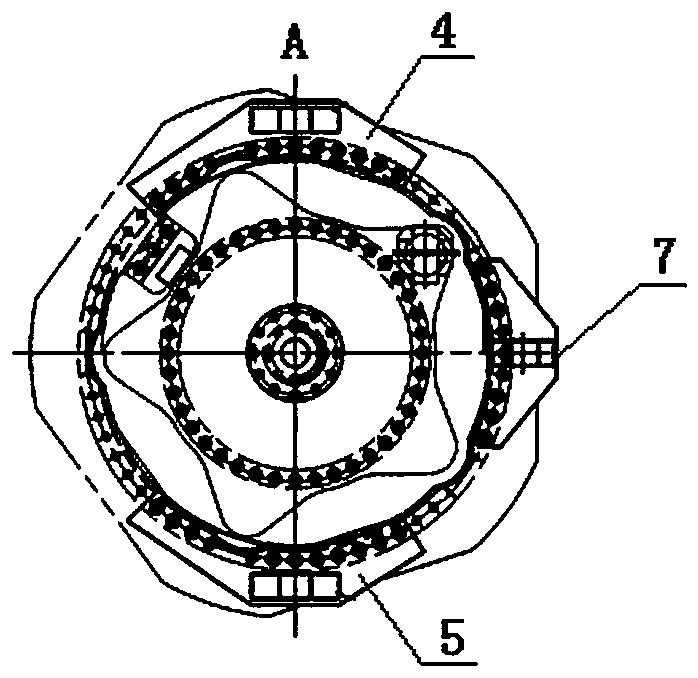

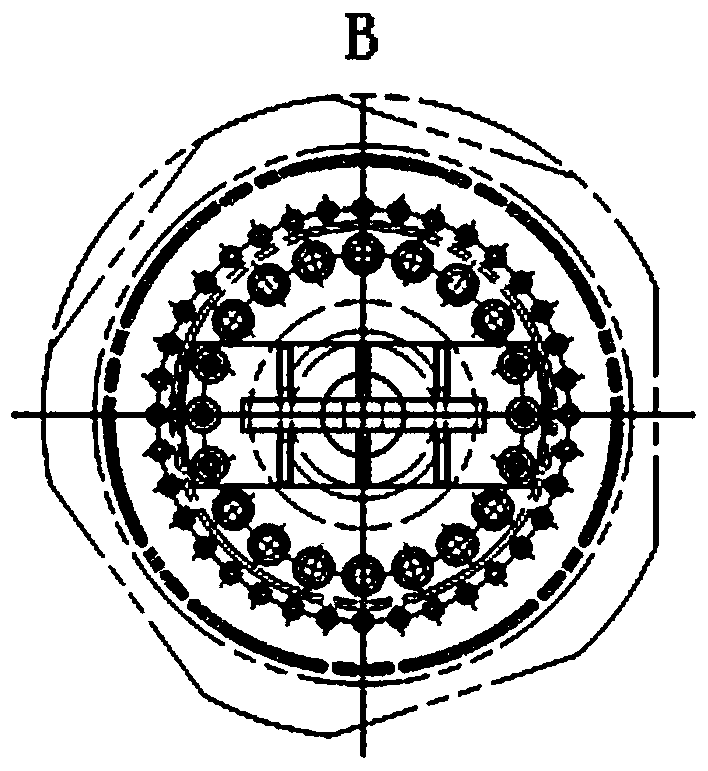

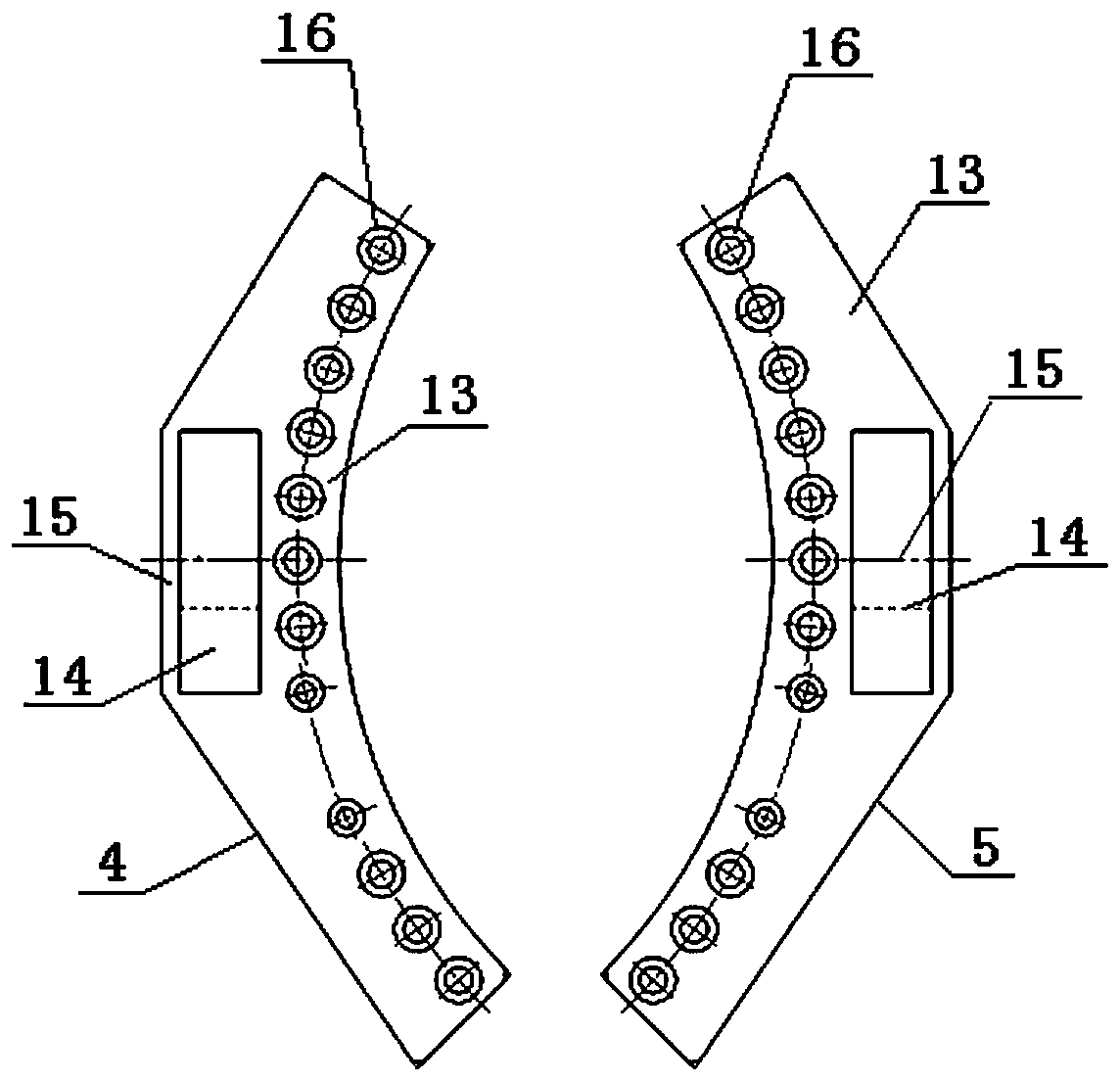

[0037] The tool used in the present invention comprises suspender 1, first, second support 2,3, first, second, third, four hanger 4,5,6,7, two supports 8, and described first, second support is formed by column 9 is formed with the base 10. There is a groove 11 at the upper end of the column, and coaxial holes 12 are formed on the two side walls of the groove. The first and second hanging parts 4 and 5 are symmetrical. There are holes 15, and there are several holes 16 on the inner circumference of the arc-shaped bottom plate to cooperate with the upper hub hole of the turbine runner. The third hanging part 6 is composed of a vertical plate 17 and a bottom plate 18. There are first and second holes in parallel on the vertical plate. 19, 20, there are several holes 21 on the circumference of the two symmetrical arcs of the bottom plate 18 to cooperate with the lower hub holes of the turbine runner, the fourth hanging part 7 is composed of a vertical plate 22 and a bottom plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com