Axial flow rotary paddle turbine runner single hook turning device

A hydraulic turbine and runner technology, which is applied in the field of axial-flow hydraulic turbine runner turn-over device, can solve problems such as failure to meet hoisting safety requirements, high requirements for power station bridge machine selection, and increased investment costs of power stations. Impulse risk, avoiding hoisting risk, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

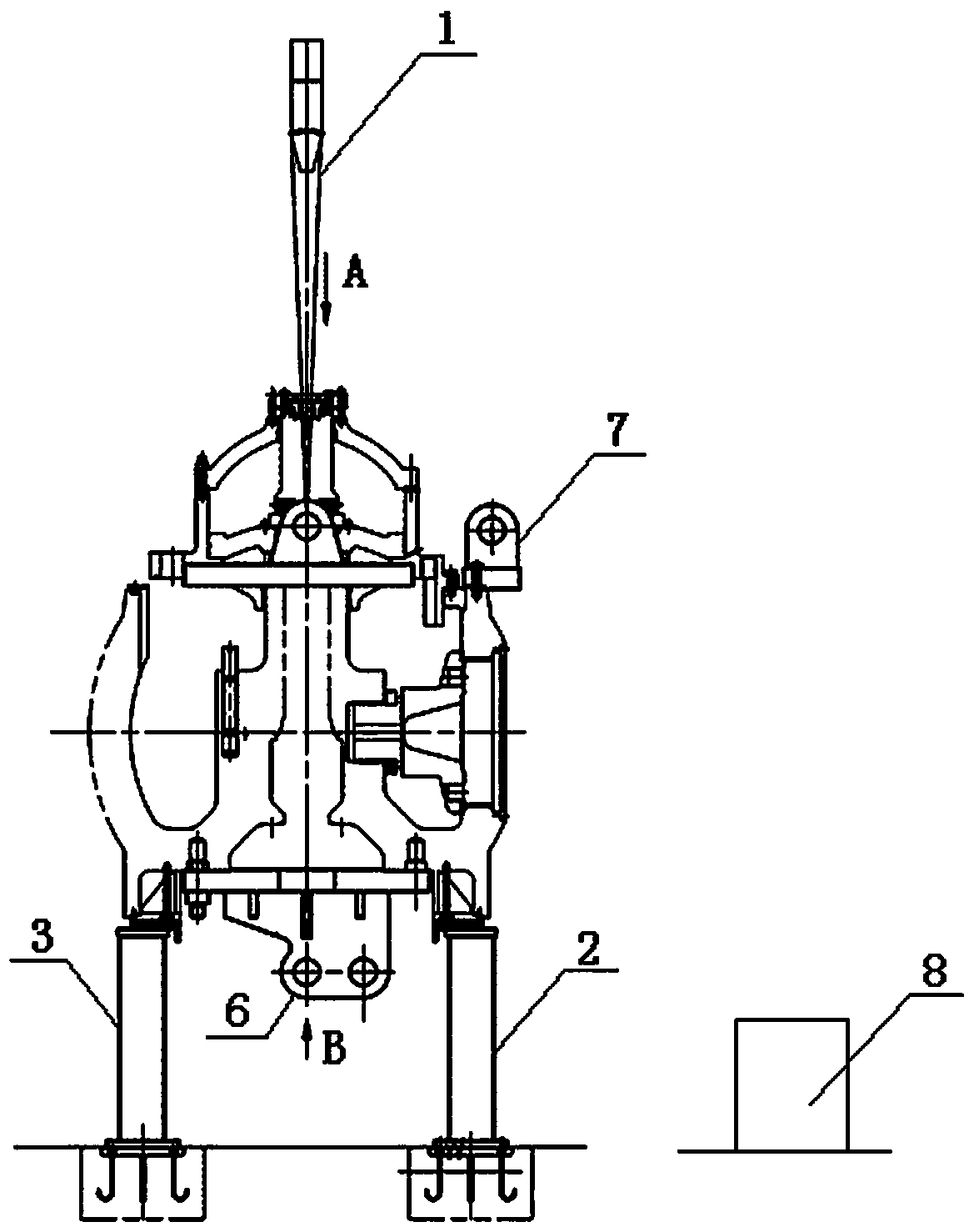

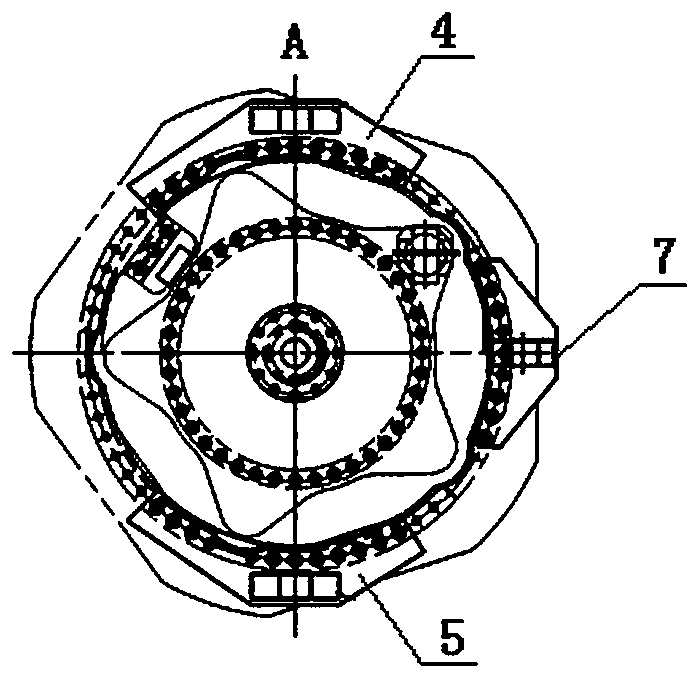

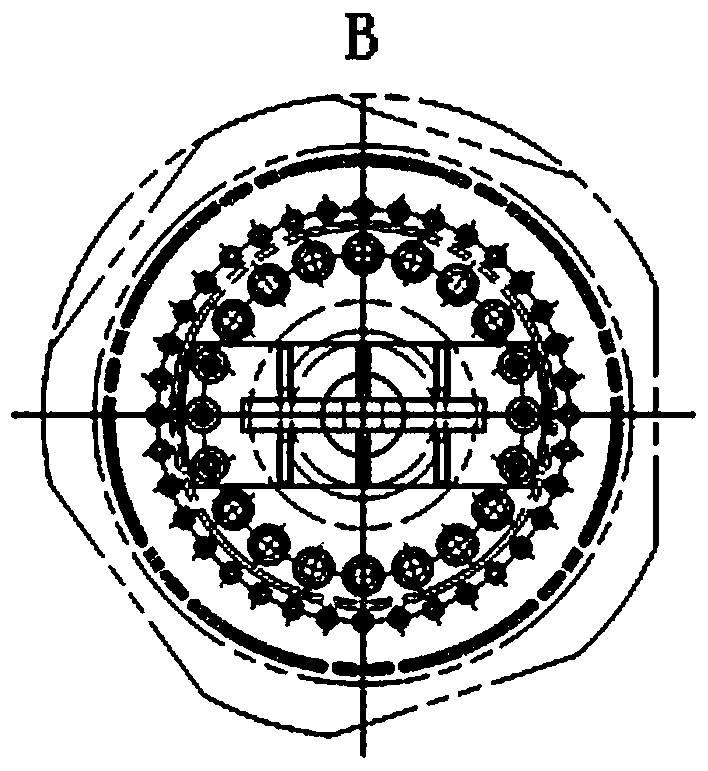

[0023] Including spreader 1, first and second brackets 2, 3, first, second, third and fourth hangers 4, 5, 6, 7, and two supports 8, the first and second brackets are composed of columns 9 and bases 10 There is a groove 11 at the upper end of the column, coaxial holes 12 are formed on the two side walls of the groove, the first and second hanging parts 4 and 5 are symmetrical, and there is a hinge seat 14 on the arc-shaped bottom plate 13, and there are holes 15 on the hinge seat. , there are several holes 16 on the inner circumference of the arc-shaped bottom plate to cooperate with the hub holes on the runner of the water turbine, and the third hanging member 6 is composed of a vertical plate 17 and a bottom plate 18, and the vertical plate has the first and second holes 19 and 20 arranged side by side. There are several holes 21 on the circumference of two symmetrical arcs of the base plate 18 to cooperate with the lower hub holes of the water turbine runner. Several holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com