Refrigeration equipment for refrigeration house

A technology for refrigeration equipment and cold storage, which is used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of hindering the heat transfer of air refrigerants, reducing cooling efficiency, and poor cooling effect, so as to facilitate heat transfer, avoid blocking, increase The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are given in conjunction with the embodiments.

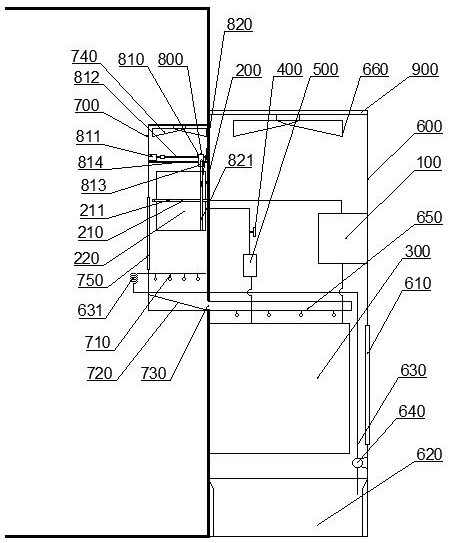

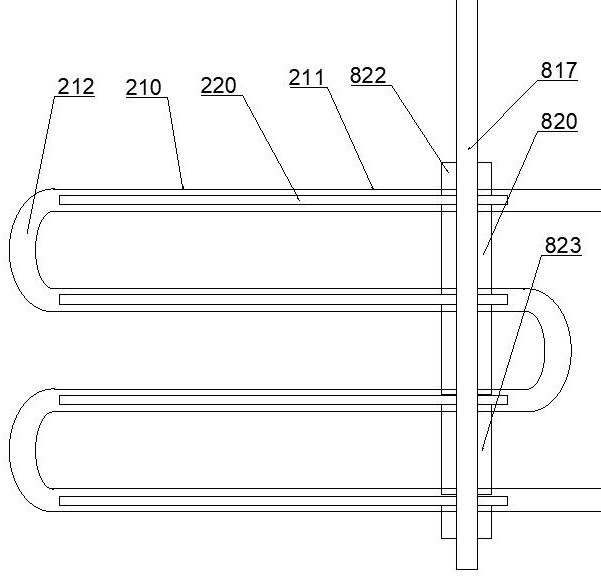

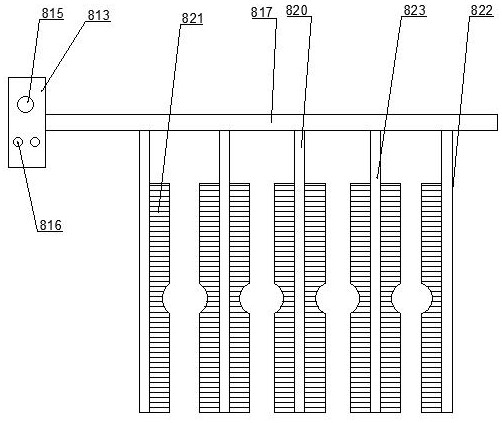

[0021] like figure 1 , a cold storage refrigeration equipment, including a compressor 100, an evaporator 200, a condenser 300, a throttle valve 400 and a drying filter 500, the suction port of the compressor 100 is connected to the evaporator 200, and the compressor The air outlet of 100 is connected to the inlet of the condenser 300 through pipelines, the outlet of the condenser 300 is connected to the drying filter 500 through pipelines, and the drying filter 500 is connected to the evaporator 200 through pipelines. A throttle valve 400 is arranged on the pipeline between the filter drier 500 and the evaporator 200 to realize the successful operation of the entire refrigeration cycle of the refrigeration equipment, and also includes a main body box 600 and an evaporati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap