Fuel cell stack, fuel cell and vehicle

A fuel cell stack and core technology, applied in fuel cells, power system fuel cells, circuits, etc., can solve the problems of fuel cell stack performance, reduce volume power density, etc., to improve volume power density and occupy space Small, the effect of isolating electric transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

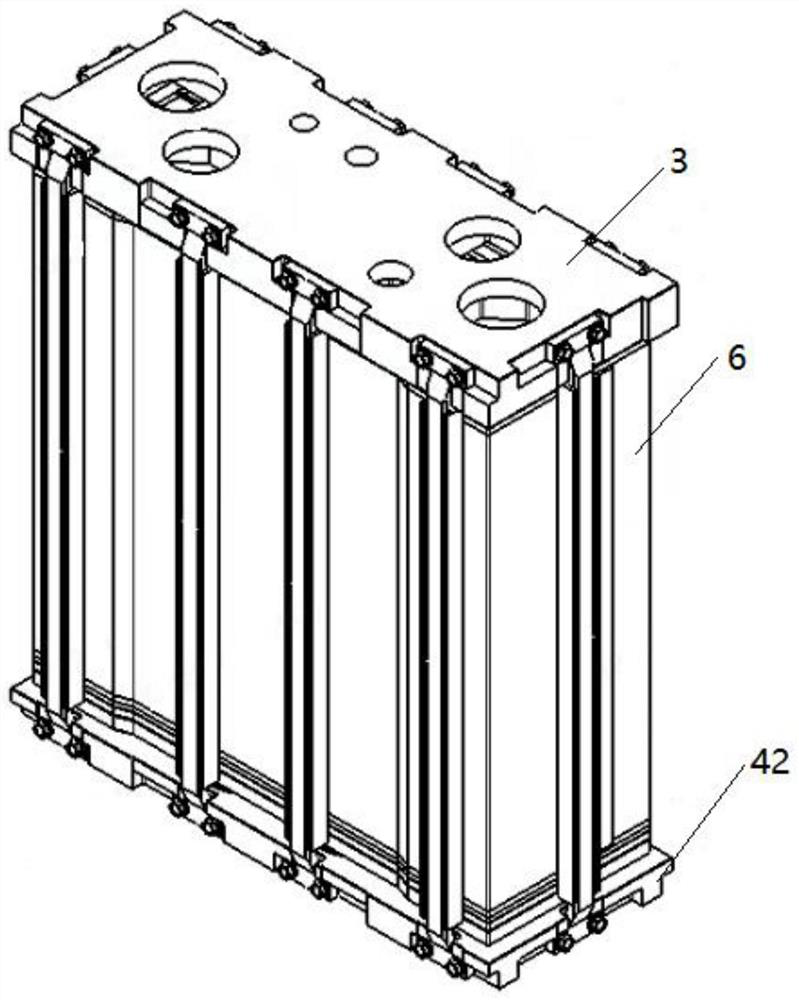

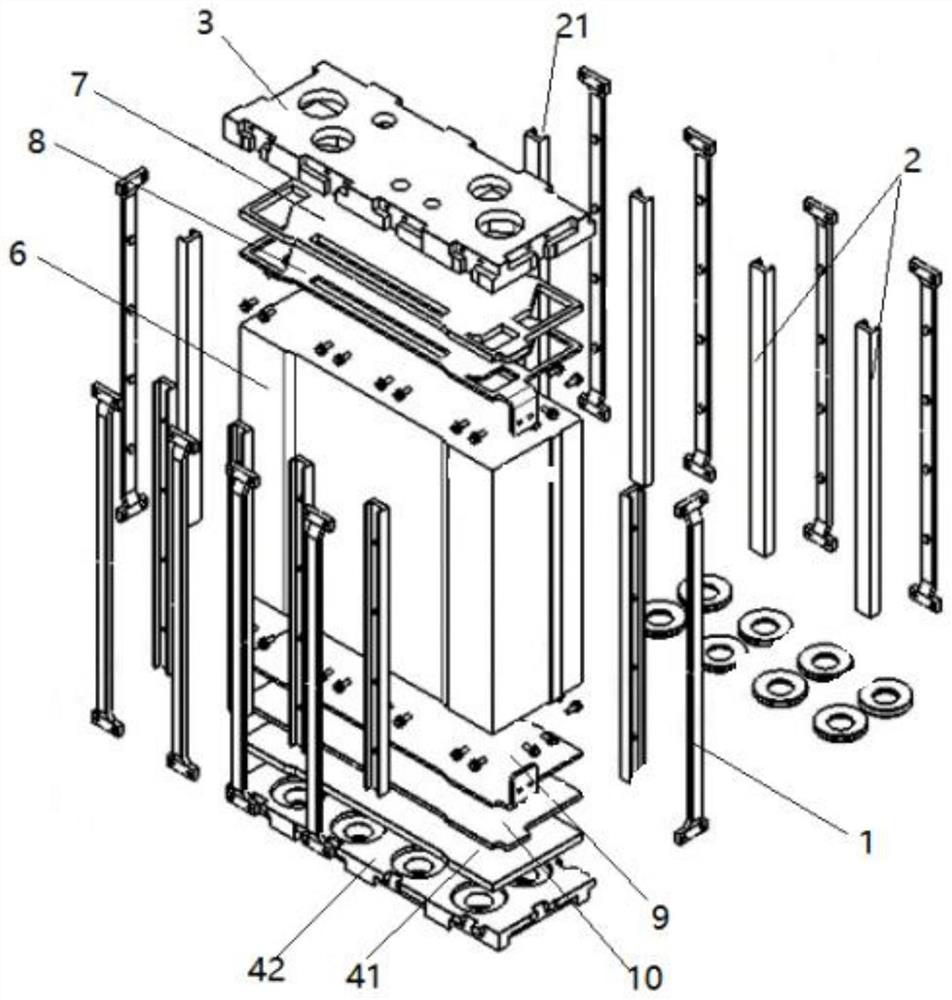

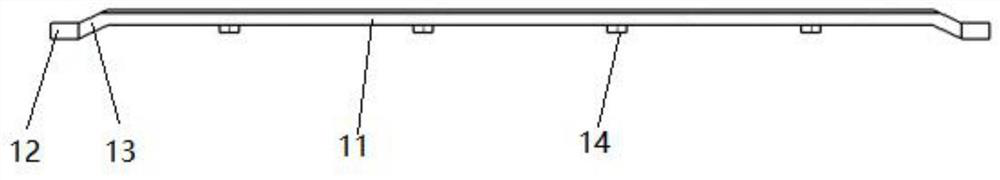

[0031] Such as Figure 1-Figure 7 As shown, a fuel cell stack provided by the present invention includes at least four tie rods 1 and insulating rods 2 having the same number as the tie rods 1; wherein: at least four tie rods 1 are distributed on four sides of the fuel cell stack, The tie rod 1 includes the body of the tie rod 1 and the connection parts 12 located at both ends of the body of the tie rod 1. The tie rod 1 is respectively connected to the side of the intake end plate 3 and the side of the blind end sealing plate 4 of the fuel cell stack through the connection parts 12 to realize air intake. The fixed positioning of the end plate 3 and the blind end sealing plate 4 in the packaging direction means that in this embodiment, the tie rod 1 is on the other four sides where the inlet end plate 3 and the blind end sealing plate 4 are not provided. And the sides of the air inlet end plate 3 and the blind end sealing plate 4 are all provided with a sinking groove 5 for acc...

Embodiment 2

[0046] Based on the same inventive concept, the present invention also provides a fuel cell, including a casing and the fuel cell stack provided in Embodiment 1, and the fuel cell stack is arranged in the casing. The present invention does not specifically limit the type and type of the fuel cell, and can be any fuel cell in the prior art, such as a proton exchange membrane fuel cell, etc. Other unspecified structures of the fuel cell can refer to the prior art Relevant disclosures are not explained here.

Embodiment 3

[0048] Based on the same inventive concept, the present invention also provides a vehicle, including the fuel cell provided in Embodiment 2, that is, the fuel cell stack of the vehicle adopts the structure of the fuel cell stack provided in Embodiment 1, and the The insulating rod 2 is connected and fixed. The present invention does not specifically limit the type and type of the vehicle. It can be any vehicle in the prior art, such as a family car, passenger car, truck, etc. Other unspecified structures of the vehicle can refer to relevant disclosures in the prior art. , no expansion description will be made here.

[0049] Through the above embodiments, the present invention has the following beneficial effects or advantages:

[0050] 1) In the fuel cell stack provided by the present invention, the volume of the entire stack is reduced by using tie-rod fasteners, and counterbores are provided on the side of the end plate to ensure that the surface of the end plate is flush a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com