Anti-noise microphone with high electromagnetic compatibility

An electromagnetic compatibility and microphone technology, which is applied in the field of microphones, can solve the problem that the microphone has no anti-noise function, and achieve the effects of improving anti-noise effect, improving working stability, and preventing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

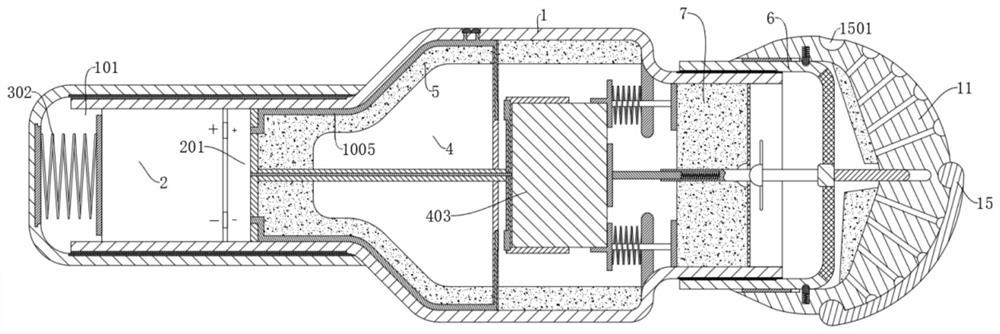

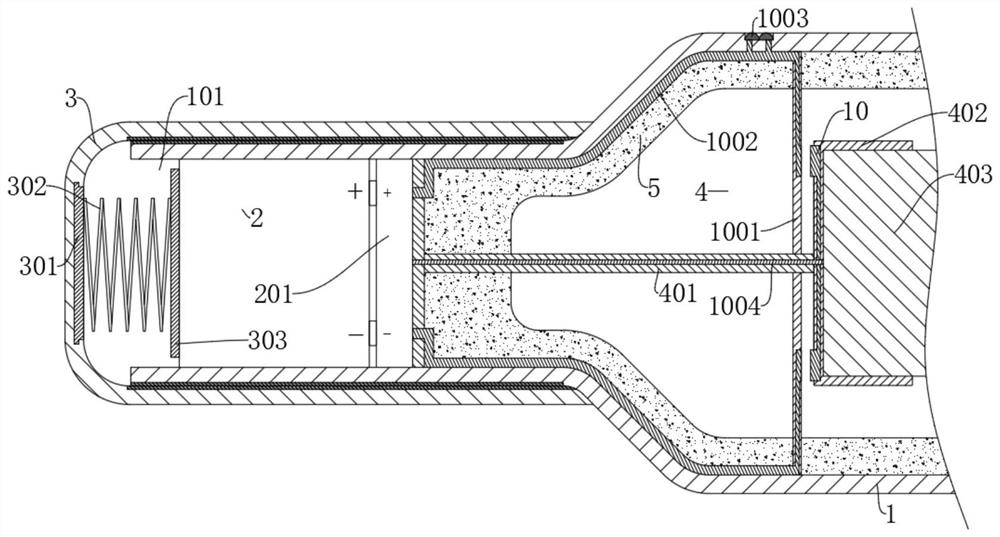

[0030] refer to Figure 1-6 , a high electromagnetic compatibility anti-noise microphone, including a housing 1 and a microphone assembly 403, and also includes: a hollow cavity 4, located in the housing 1; a connecting seat 402, connected in the hollow cavity 4, and the microphone assembly 403 is connected in Inside the connecting seat 402; the second sound-absorbing cotton 7 is slidably connected in the housing 1; the fixed network cable 704 is fixedly connected in the housing 1 and attached to the second sound-absorbing cotton 7; the threaded sleeve 6 is screwed in the housing At one end of 1, the threaded sleeve 6 is provided with a hollow net 601; the threaded sleeve 6 is provided with a fixing mechanism that can simultaneously compress and fix the network cable 704 and the microphone assembly 403; the outside of the threaded sleeve 6 is connected with an adjustment mechanism that can manually adjust the volume; The first sound-absorbing cotton 5 is wrapped inside the cas...

Embodiment 2

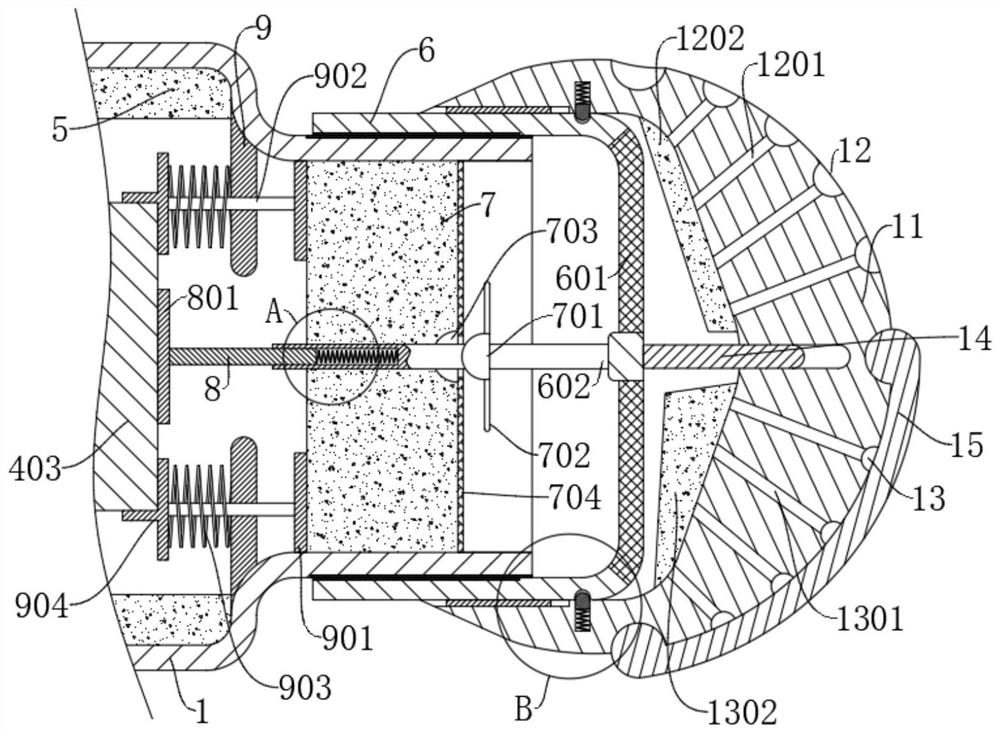

[0034] refer to Figure 1-6 , on the basis of Example 1, further,

[0035] The fixing mechanism includes a second connecting rod 602 and a second pressing plate 801, the second connecting rod 602 is rotatably connected to the inner wall of the threaded sleeve 6, the second connecting rod 602 is connected with a pressing rod 702, and the second connecting rod 602 is slidably connected with a third The connecting rod 8 , the second spring 802 is connected between the third connecting rod 8 and the inner wall of the second connecting rod 602 , and the second pressing plate 801 is connected to an end of the third connecting rod 8 away from the second connecting rod 602 .

[0036] The second connecting rod 602 is fixedly connected with a ball block 701, the pressure rod 702 is fixedly connected with the ball block 701, the second sound-absorbing cotton 7 is provided with a groove 703 corresponding to the ball block 701, and the second connecting rod 602 runs through the first Two ...

Embodiment 3

[0040] refer to Figure 1-6 , on the basis of Example 2, further,

[0041] The housing 1 is provided with a fixed plate 9, on which a sliding rod 902 is slidably connected, and the two ends of the sliding rod 902 are respectively connected with a push plate 901 and a centralizing plate 904, and the push plate 901 is attached to the second sound-absorbing cotton 7, The centralizing plate 904 is attached to the microphone assembly 403 , the third spring 903 is sleeved on the sliding rod 902 , and the third spring 903 is located between the centralizing plate 904 and the fixing plate 9 .

[0042] The pressing rod 702 drives the fixed wire 704 to move and squeeze the second sound-absorbing cotton 7 , and at the same time, the second sound-absorbing cotton 7 moves inwardly, pushing the push plate 901 to move, and the microphone assembly 403 is further fixed by the centralizing plate 904 .

[0043] At the same time, both ends of the third spring 903 are fixed on the centralizing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com