Digital laminating and embossing machine floating roller control synchronizing device and method

A technology of lamination embossing machine and synchronization device, which is applied to the floating roller control synchronization device and field of digital lamination embossing machine, which can solve the problems of the lamination paper embossing not meeting the requirements, increasing defective products, and reducing the contact surface, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

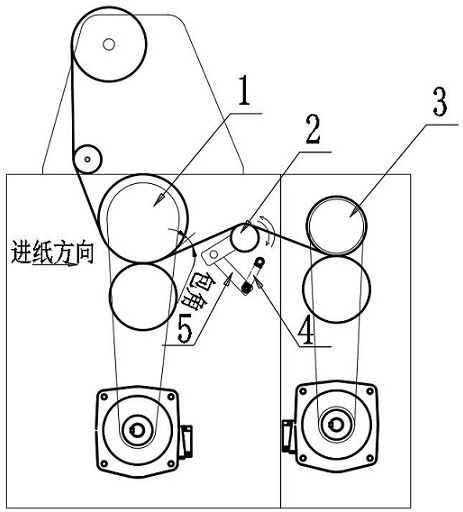

Embodiment 1

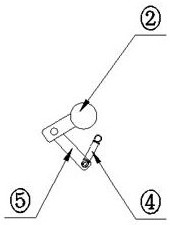

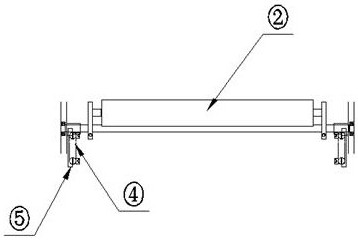

[0011] Embodiment 1: with reference to attached Figure 1-3 . A digital film embossing machine floating roller control synchronization device, the heating roller 1 and the cooling embossing roller 3 are controlled by their own independent motors, the floating roller 2 is positioned between the heating roller 1 and the cooling embossing roller through the swing arm 5 and the tension spring 4 Between rolls 3. The fixing of floating roller 2 is by swing arm 5, and swing arm 5 is pulled by extension spring 4. The swing arm 5 has a V-shaped structure, and one end of the swing arm 5 is connected to the floating roller 2 , and the other end of the swing arm 5 is connected to the extension spring 4 .

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, a method for synchronizing the floating roller of a digital film embossing machine to control the heating roller and the cooling embossing roller. The heating roller 1 and the cooling embossing roller 3 are respectively controlled by independent motors , when the coated paper passes through the coating gap formed by the heating roller 1 roller surface and the rubber roller roller surface to the cooling embossing roller 3, when the speed of the heating roller 1 and the cooling embossing roller 3 are different, it is The film-coated paper depends on the up and down swing of the floating roller 2 to adapt to the asynchrony of the heating roller 1 and the cooling roller 3 . When the floating roller 2 is lifted up, the contact area between the coated paper and the heating roller surface is increased (that is, the area of the coated paper covering the heating roller increases), and the contact area between the coated paper and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap