Shell embossing device for LED lamp holder production

A technology of LED lamp holder and rolling device, which is applied in the direction of decorative arts and embossed decorations, etc. It can solve the problems of loosening, reducing the embossing speed, and the LED lamp holder is biased to one side, so as to ensure the quality of embossing and improve the quality of embossing. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

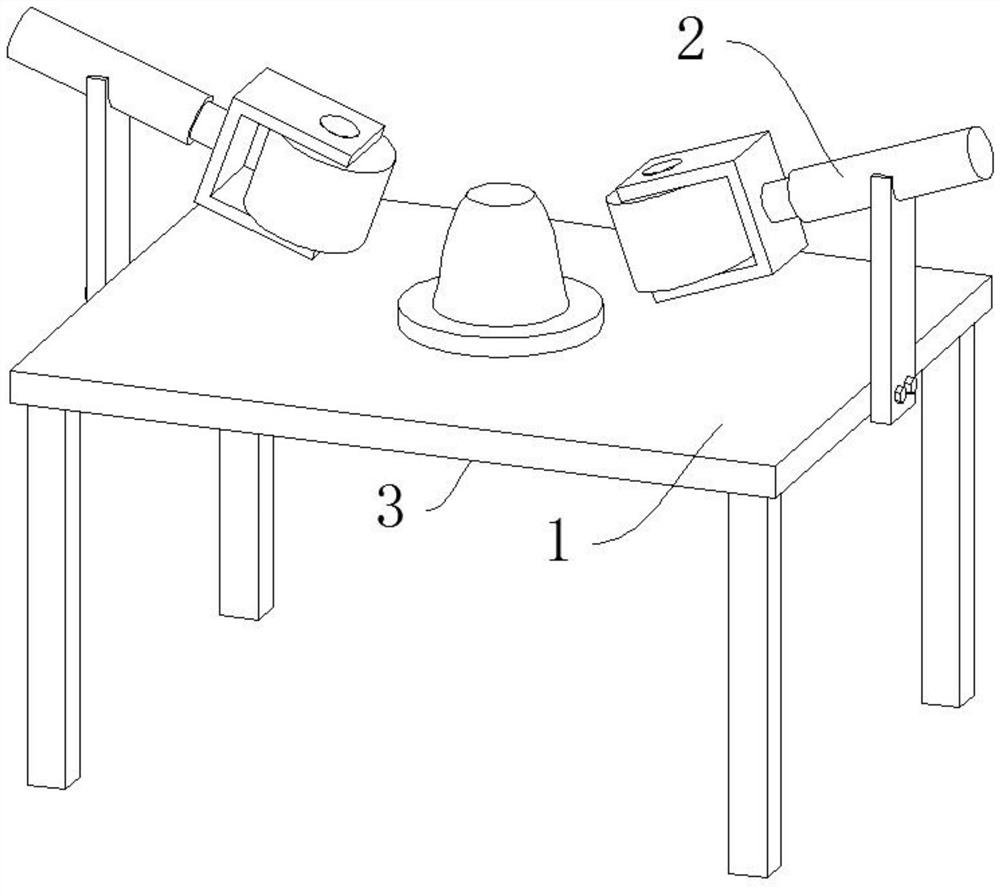

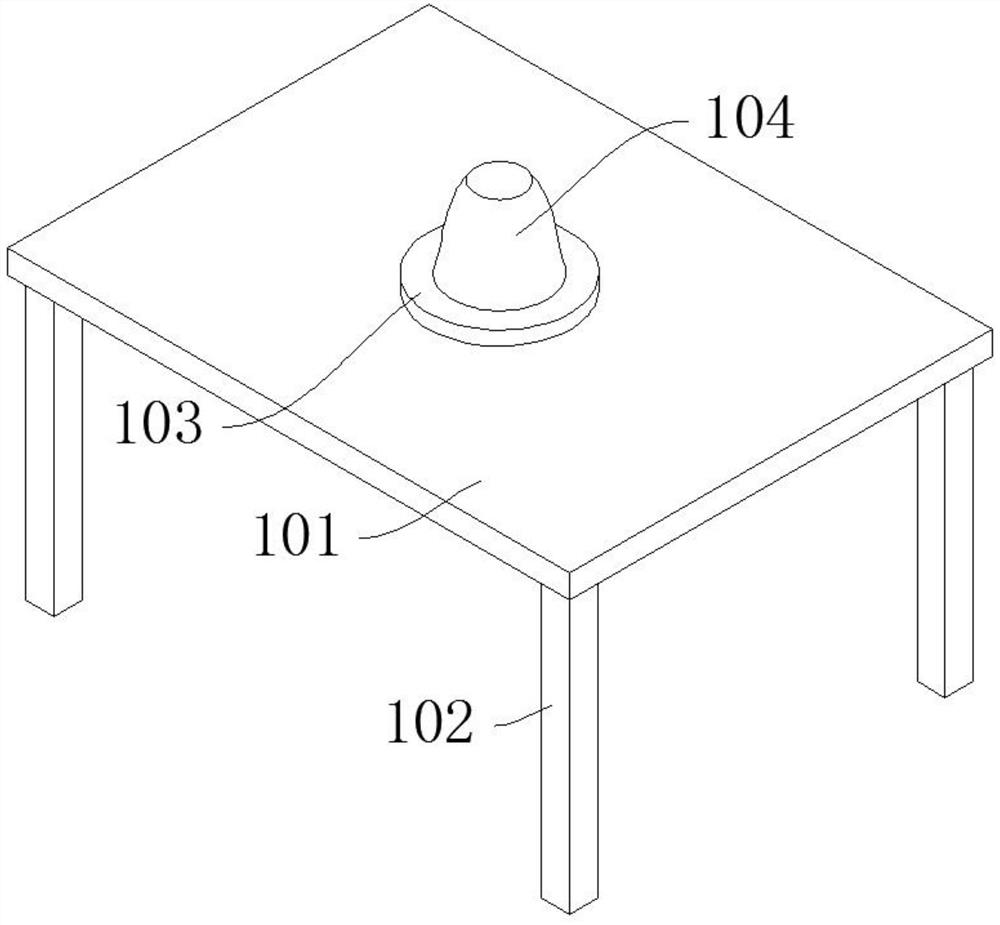

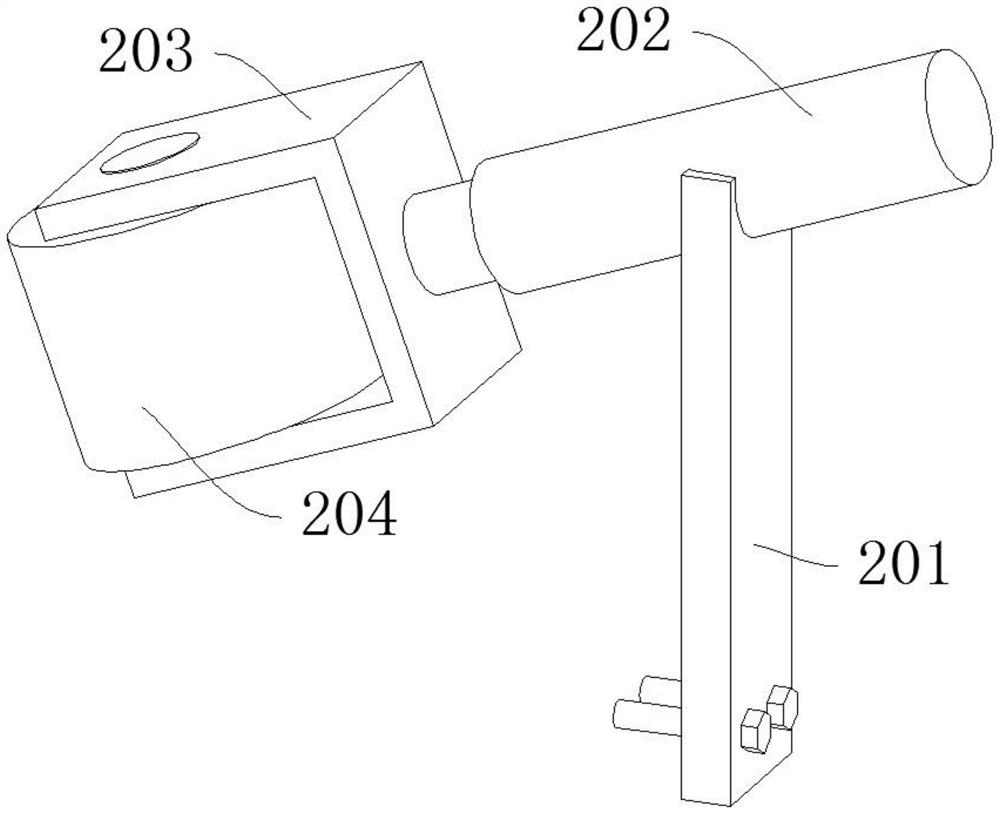

[0029] Such as Figure 1-Figure 4 As shown, the shell embossing device for LED lamp holder production includes a table frame device 1 for support and a rolling device 2 for rolling forming. A power device 3 is installed under the table frame device 1, and the rolling device 2 is symmetrical. Setting; the table frame device 1 includes a support platform 101, four support legs 102 are evenly distributed at the four corners of the bottom of the support platform 101, a supporting plate 103 is installed on the supporting platform 101, and a positioning block 104 is installed on the supporting plate 103; the rolling device 2 includes A support frame 201, a telescopic cylinder 202 is installed on the support frame 201, a connecting seat 203 is installed on one side of the telescopic cylinder 202, and an embossing roller 204 is installed in the connecting seat 203.

[0030] Further: the power unit 3 includes a motor base 302, a motor 303 is installed on the motor base 302, a first gea...

Embodiment 2

[0032] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the power unit 3 includes an electric push rod 307, a rack 306 is installed behind the electric push rod 307, a third gear 305 is arranged on one side of the rack 306, and the electric push rod 307 They are bolted to the support platform 101 and the rack 306 respectively, and the third gear 305 is connected to the supporting plate 103 with a flat key.

[0033] The working principle and application process of the present invention: Insert the LED lamp holder on the positioning block 104, the support frame 201 fixes the telescopic cylinder 202, pushes the connecting seat 203 and the embossing roller 204 to squeeze the LED lamp holder from both sides, and the motor holder 302 fixes the motor 303 drives the second gear 301 through the first gear 304 to drive the supporting plate 103 to rotate, or the electric push rod 307 pushes the rack 306 to expand and contract, meshes with the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com