Intelligent feeder applied to material collecting and discharging inspection

A feeder, rewinding and unwinding technology, applied in thin material handling, labels, winding strips, etc., can solve the problems of incompatibility with mass production activities, cumbersome operations, easy to misuse, etc., to meet the needs of mass production. The needs of activities, the effect of ensuring accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

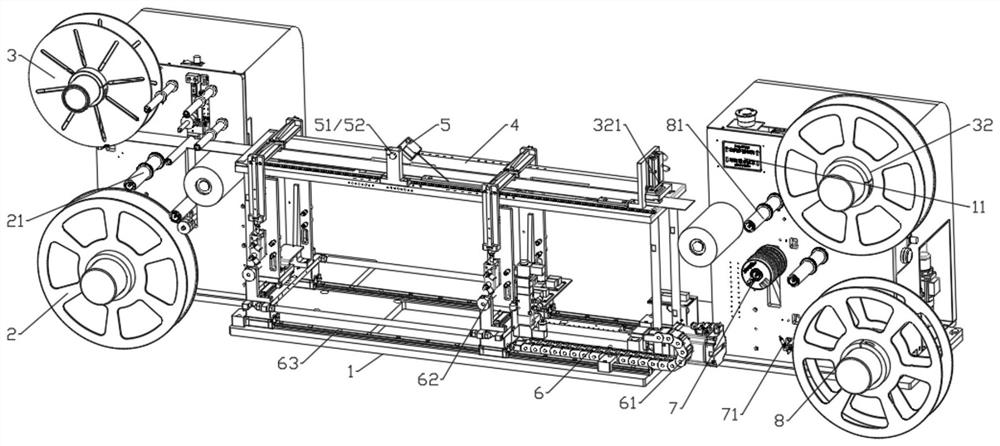

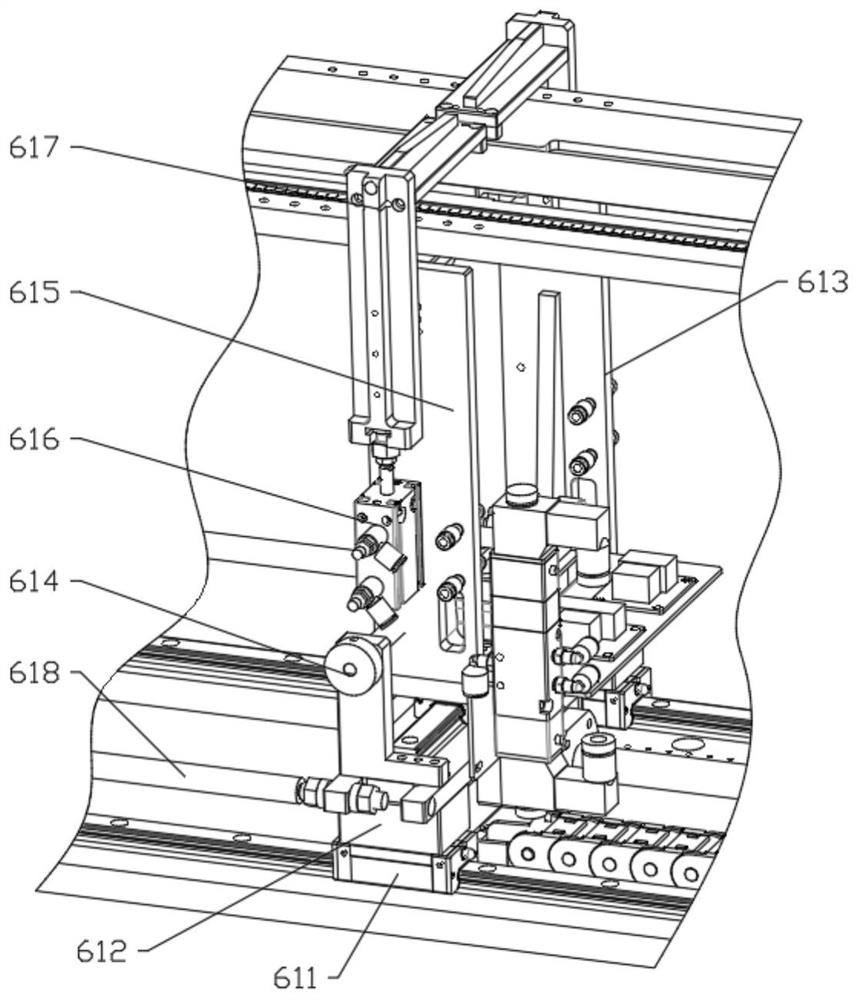

[0017] see figure 1 , the present invention provides an intelligent feeder for feeding and unwinding inspection, comprising: a frame 1, a feeding wheel 2 arranged at one end of the frame 1, and a film feeding device arranged above the feeding wheel 2 Wheel 3, the material guide platform 4 arranged at the rear end of the feeding wheel 2, some first guide rollers 21 arranged between the material feeding wheel 2 and the material guide platform 4, the first material guide rollers 21 arranged on the material guide platform 4 The visual detection mechanism 5 on the top, the material pulling mechanism 6 arranged on the side of the material guide platform 4, the counterweight wheel 7 arranged at the rear end of the material guide platform 4, and some of the counterweight wheels 7 arranged on the side The second guide roller 81 and the receiving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com