Multifunctional tool box for bridge detection

A bridge inspection and toolbox technology, applied in bridges, manufacturing tools, bridge parts, etc., can solve the problems of reducing the service life of inspection tools, easy-to-damage inspection tools, and inspection tool collisions, reducing the range of up and down bumps and simple structure , to reduce the effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

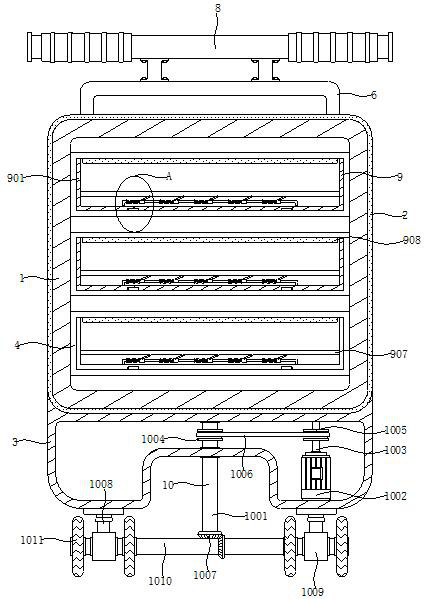

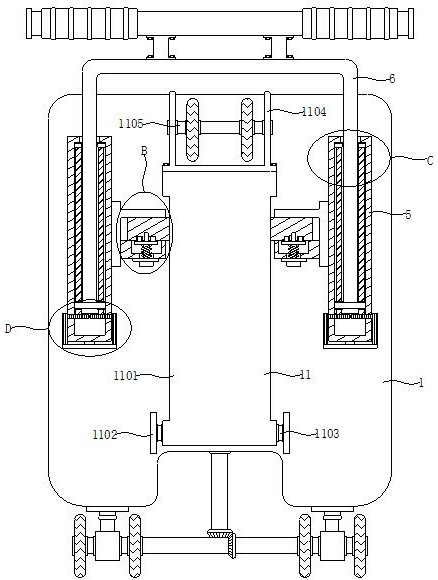

[0028] see Figure 1-7, the present invention provides a technical solution: a multifunctional toolbox for bridge detection, including a toolbox 1, the outer wall of the toolbox 1 is fixedly provided with a sunscreen and heat insulation layer 2, and the bottom outer surface of the sunscreen and heat insulation layer 2 The running box 3 is fixedly installed, and the inner wall of the tool box 1 is fixedly installed with three sets of back-shaped plates 4 sequentially from top to bottom. The rear outer surface of the tool box 1 is provided with U-shaped rods 6 and two sets of sleeves 5 are fixedly installed, The two ends of the U-shaped rod 6 are respectively inserted into the two sets of sleeves 5 and extend to the inside of the two sets of sleeves (5). The outer surface of the top of the tool box is fixedly connected with a long handle 8 by bolts, and the interior of the three groups of return-shaped plates 4 is provided with a shock-absorbing mechanism 9, the running box 3 is...

Embodiment 2

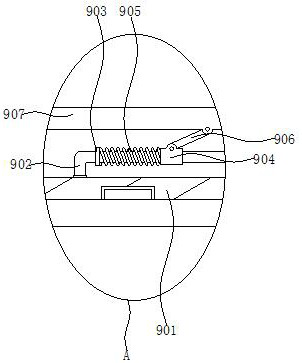

[0030] see Figure 1-7 , on the basis of Embodiment 1, the shock absorbing mechanism 9 includes a drawer box 901, a U-shaped slide bar 902, a fixed sleeve 903, a slide bar cover 904, a telescopic spring 905, a connecting rod 906, a shock absorbing plate 907 and a rubber plate 908 , the drawer box 901 is located in the back-shaped plate 4, the inner bottom of the drawer box 901 is fixedly connected with a U-shaped slide bar 902, and five sets of fixed sleeves 903 and slide bar sets 904 are slidably installed on the U-shaped slide bar 902. There are five groups of telescopic springs 905 set on the top of the sliding rod 902, and the ends of each fixed sleeve 903 adjacent to the sliding rod sleeve 904 are fixedly connected with the two ends of the five groups of telescopic springs 905, and the outer walls of the five groups of sliding rod sleeves 904 are all hinged. Connecting rods 906 are installed, and one end of the five groups of connecting rods 906 is hingedly installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com