Segment joint mechanical property test system and method considering shearing dislocation

A segment joint and test system technology, which is applied in the field of mechanical performance test system of segment joint considering shear displacement, can solve the problem that the segment shear displacement cannot be realized and the mechanical performance leakage of tunnel lining segment joint cannot be studied Water changes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

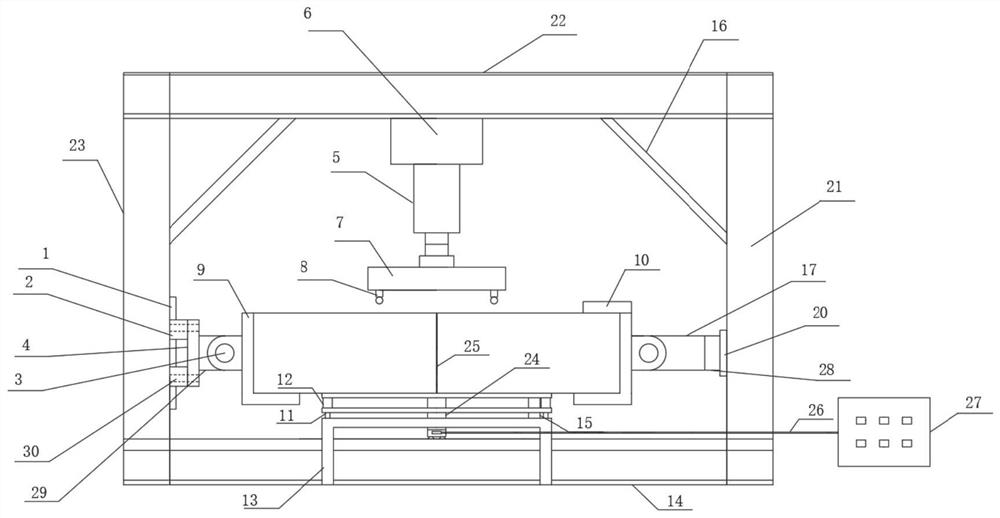

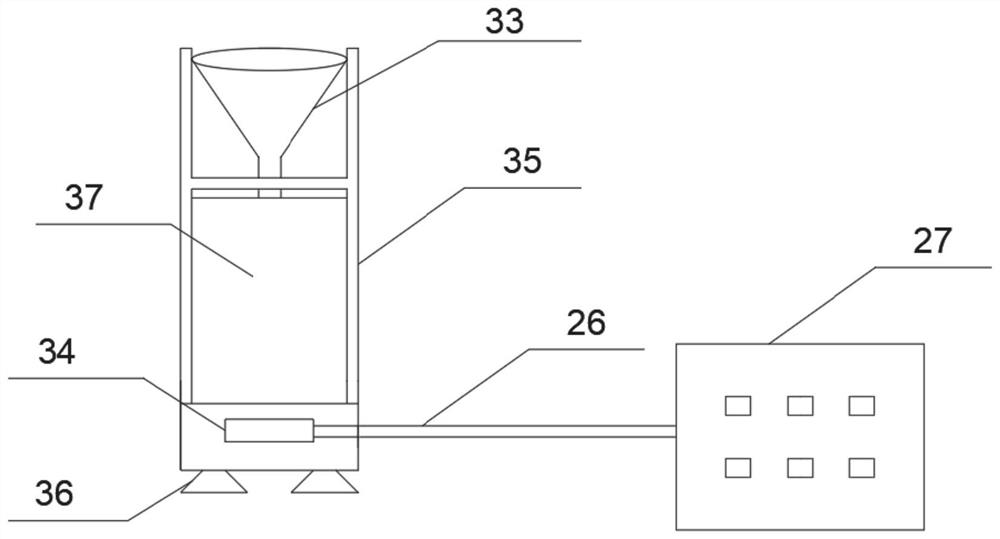

[0044] Such as figure 1 As shown, this embodiment provides a mechanical performance test system for segment joints considering shear displacement, including a frame system, a segment support system, a segment loading system, and a data acquisition system;

[0045] The segment loading system includes a vertical loading subsystem and a lateral loading subsystem. The vertical loading subsystem is arranged on the top of the frame system, which includes a vertical loading cylinder 5, a load distribution beam 7 and two telescopic cylinders 8. The vertical loading cylinder 5 is arranged on the upper part of the load distribution beam 7, and two telescopic oil cylinders 8 are detachably connected to the lower part of the load distribution beam 7, and are arranged symmetrically; the lateral loading subsystem includes a lateral loading device and a vertical sliding device, which are respectively arranged on both sides of the frame system, The lateral loading device comprises a lateral l...

Embodiment 2

[0060] This embodiment provides a test method for a test system for the mechanical properties of segment joints considering shear displacement, which is characterized in that it includes the following steps:

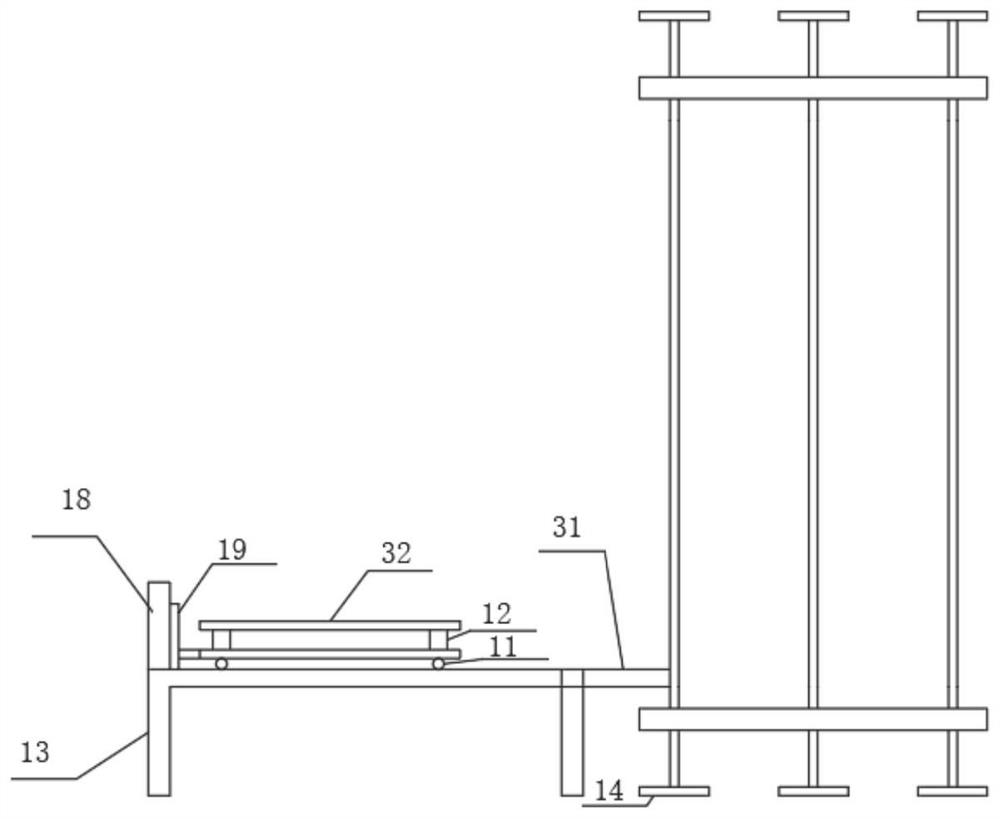

[0061] 1) Connect the pre-prepared two rectangular model segments together via bolts, and then place them on two L-shaped support plates 9;

[0062] 2) Then jack up the support cylinder 15 below the rectangular model segment near the side of the lateral loading device, so that the two rectangular model segments are in a horizontal state;

[0063] 3) Open the lateral loading cylinder 17 for preloading, and push the L-shaped support plates 9 on both sides to fully contact the rectangular model segments;

[0064] 4) Remove the support cylinder 15 below the model segment;

[0065] 5) Remove the telescopic oil cylinder on the right side of the load distribution beam, keep the telescopic oil cylinder on the left side, start the vertical loading oil cylinder 5, apply pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com