A small-diameter pipe inner wall spraying robot and its control method

A spraying robot, small-caliber technology, applied in manipulators, manufacturing tools, spraying devices, etc., can solve the problems of poor continuity and stability, low efficiency, difficult control, etc., to ensure continuity and stability, improve Operational efficiency and the effect of ensuring adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

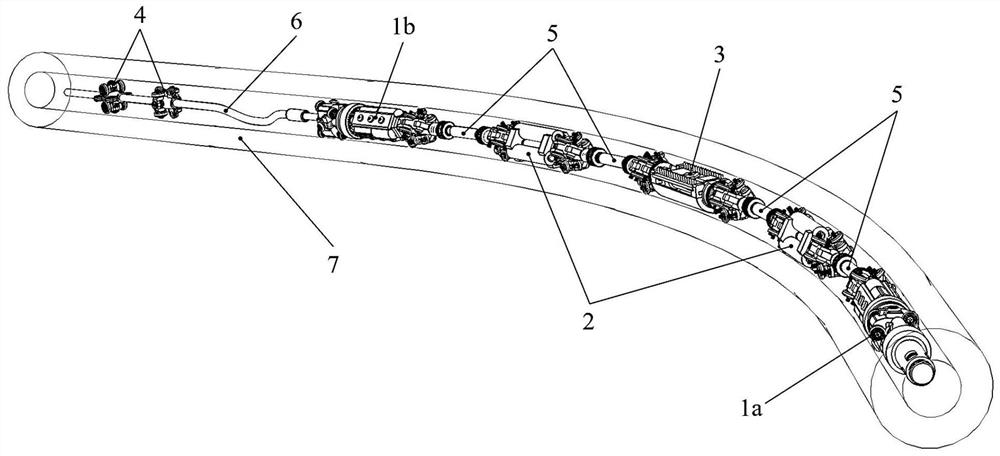

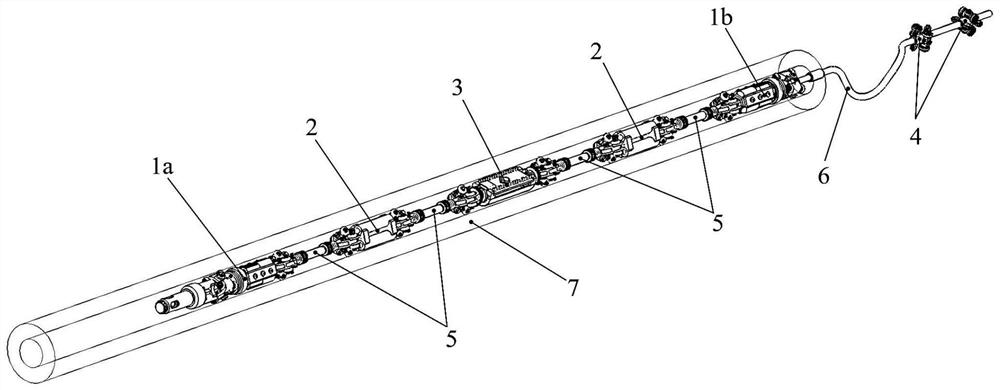

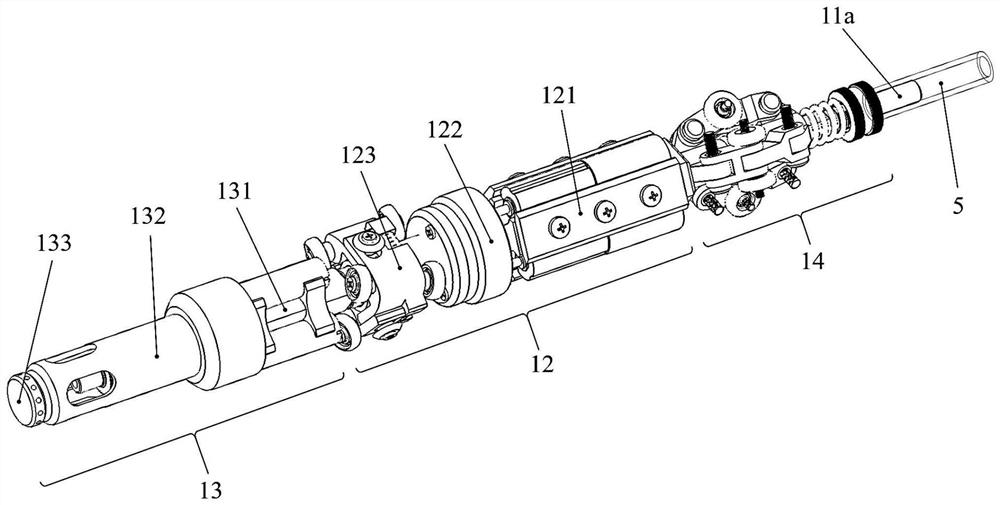

[0056] A small-diameter pipeline inner wall spraying robot, comprising a drive module, a power module, a control module, a feeding pipe support module, a feeding pipe and a hose connector; the driving module includes two types of a first driving module and a second driving module, Taking the first drive module as an example, the first drive module is composed of the first drive module main shaft, the screw drive assembly, the nozzle assembly, and the support assembly. The screw drive assembly includes a drive unit A, a rotating frame, and a screw reducing mechanism. The rotating frame will drive The driving force generated by unit A is transmitted to the helical reducing mechanism, which can be adaptively adjusted with the pipe diameter, and its driving wheel always presses the inner wall of the small-diameter pipe to be sprayed. While ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com