Grinding device

A grinding and grinding wheel technology, applied in the direction of grinding driving device, measuring device, optical device, etc., can solve the problem of high price and achieve good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

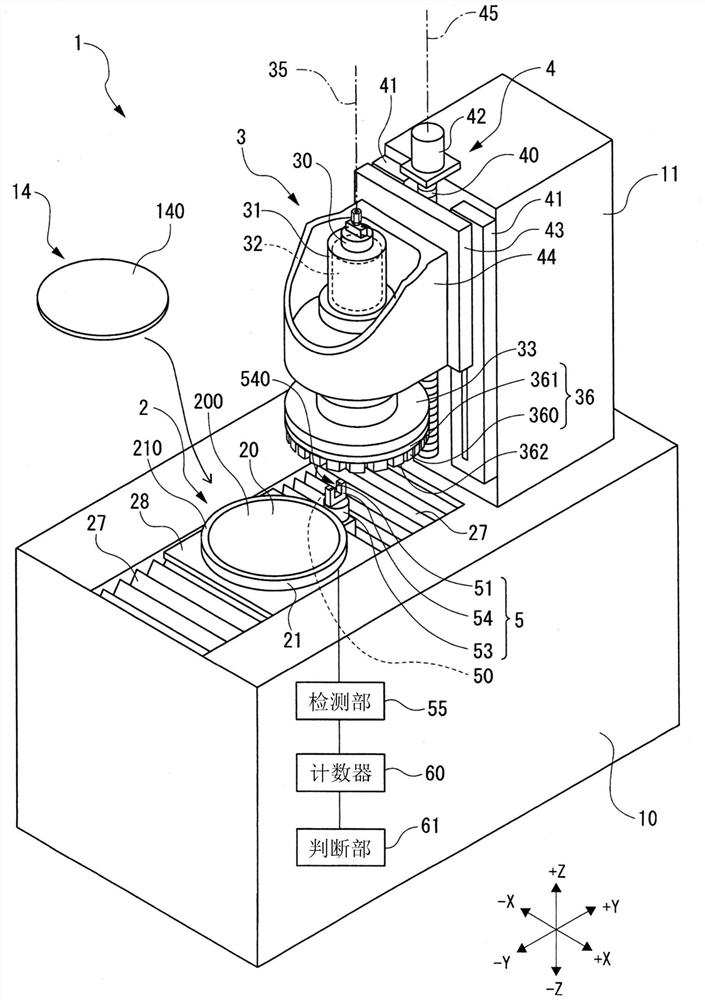

[0022] 1 The structure of the grinding device

[0023] figure 1 The shown grinding device 1 is a grinding device for grinding a workpiece 14 using a grinding unit 3 . Hereinafter, the structure of the grinding apparatus 1 is demonstrated.

[0024] Such as figure 1 As shown, the grinding apparatus 1 has: a base 10 extending in the Y-axis direction; and a column 11 erected on the +Y direction side of the base 10 .

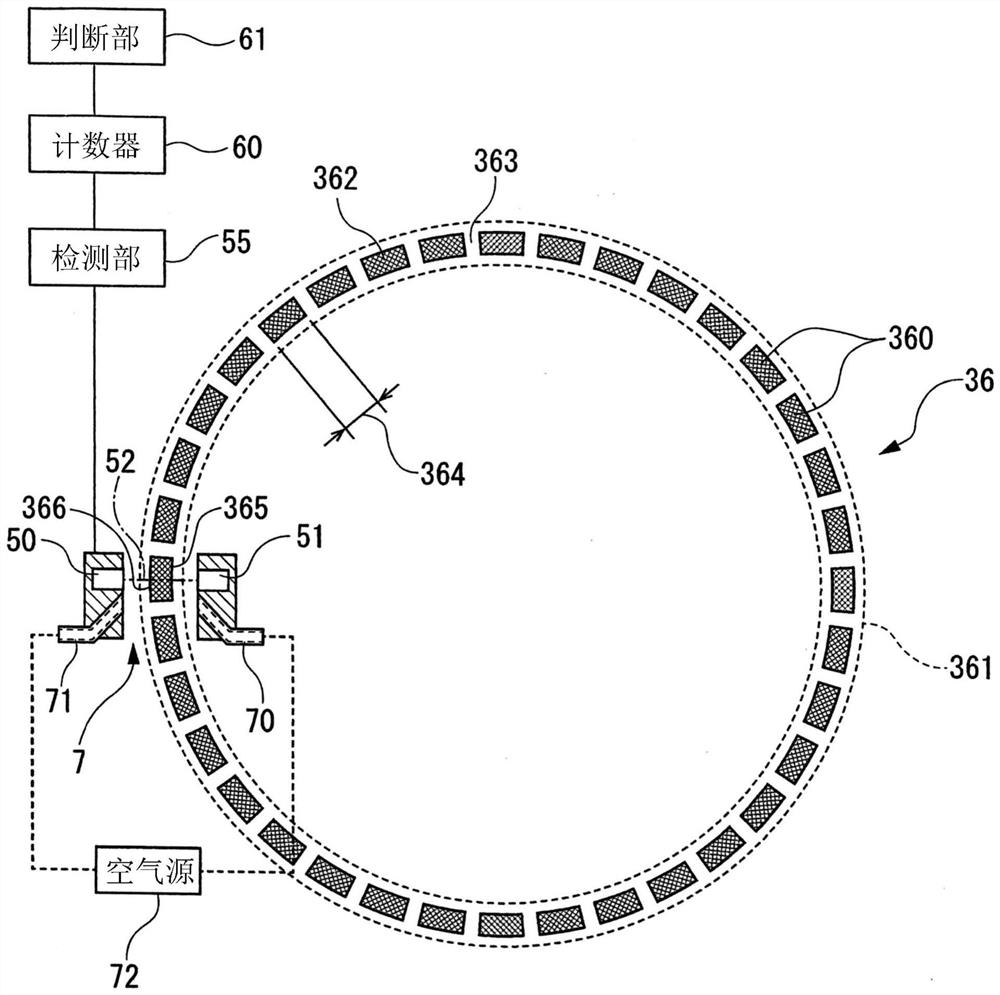

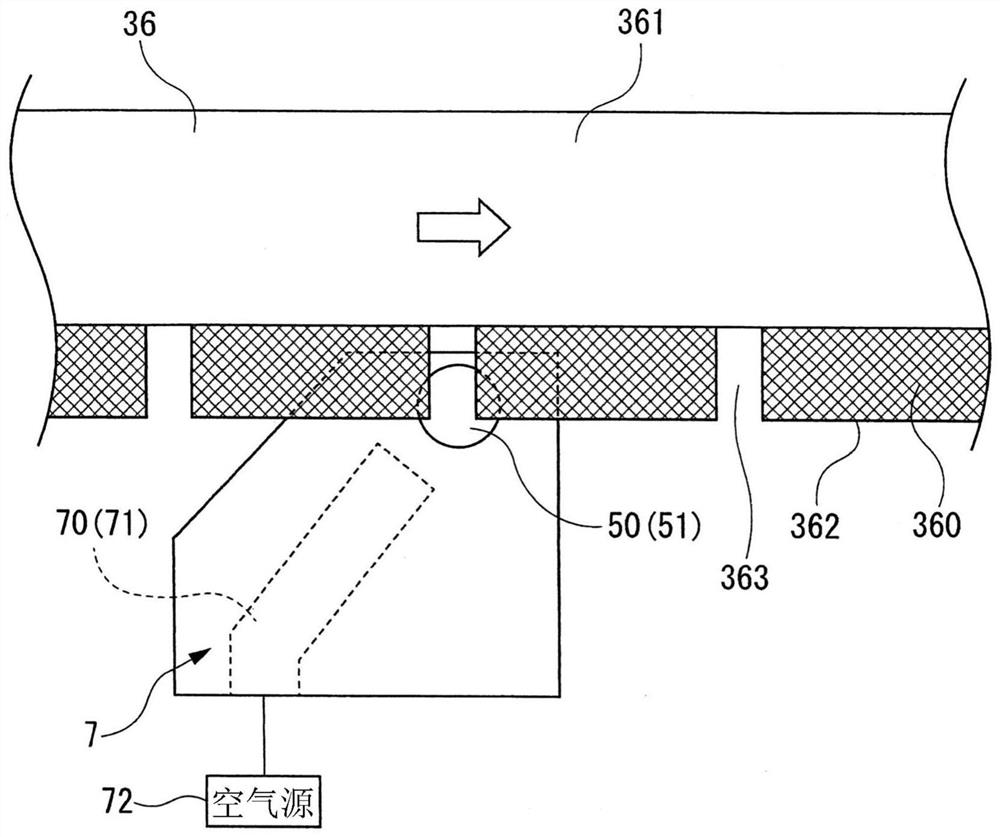

[0025] A grinding feed unit 4 that supports the grinding unit 3 is disposed on the side surface of the column 11 on the −Y direction side. The grinding unit 3 has: a main shaft 30 having a rotating shaft 35 in the Z-axis direction; a housing 31 supporting the main shaft 30 in a rotatable manner; a motor 32 rotating and driving the main shaft 30 around the rotating shaft 35; a seat 33 connected to the lower end of the spindle 30 ; and a grinding wheel 36 mounted on the lower surface of the mounting seat 33 . The grinding wheel 36 can be attached to and detached f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com