Buoy coloring machine

A buoy, color machine technology, applied in printing presses, rotary printing machines, printing and other directions, can solve the problem of slow color application efficiency, and achieve the effect of improving work efficiency, stability, and color application efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

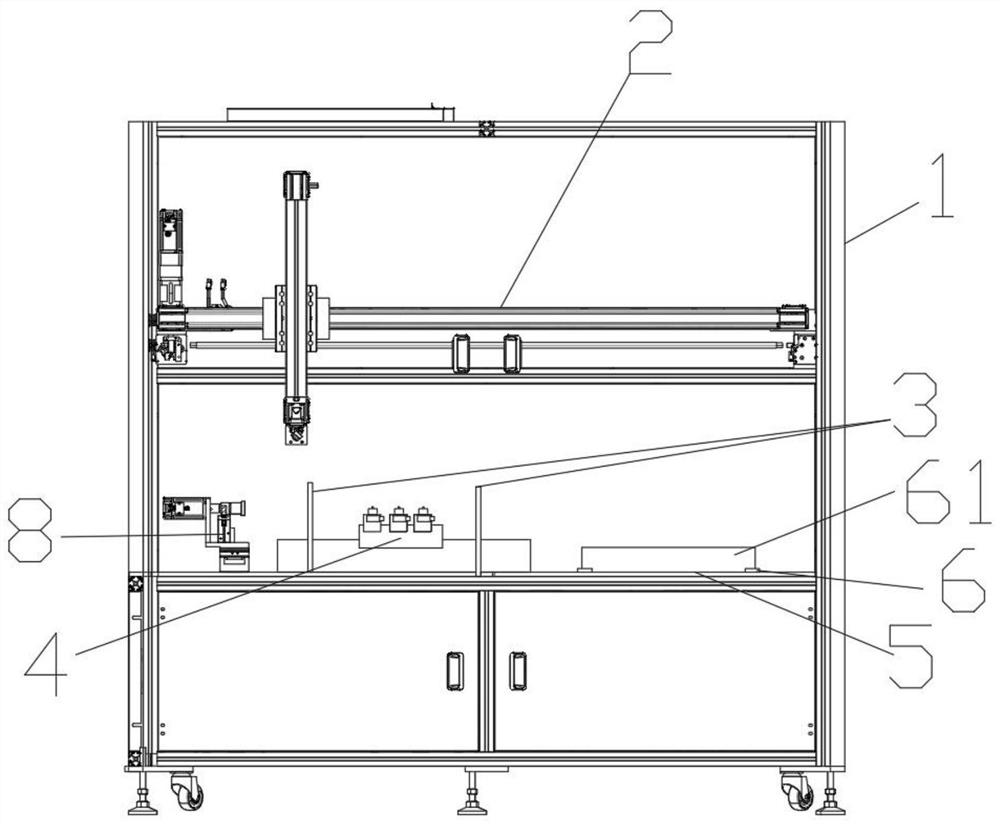

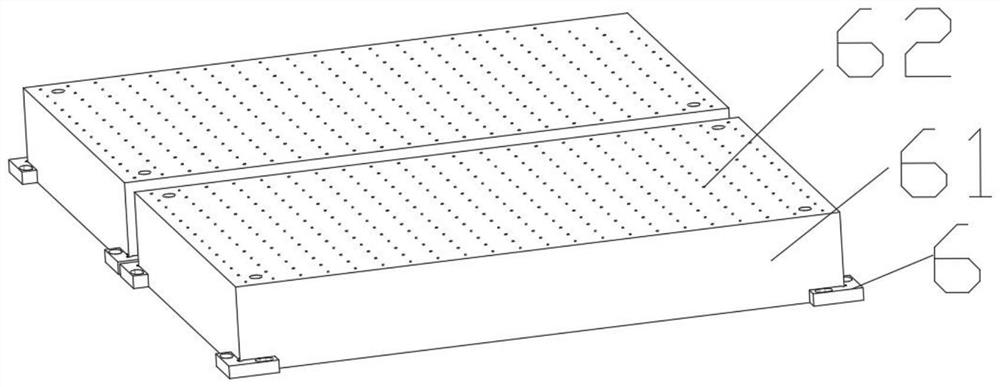

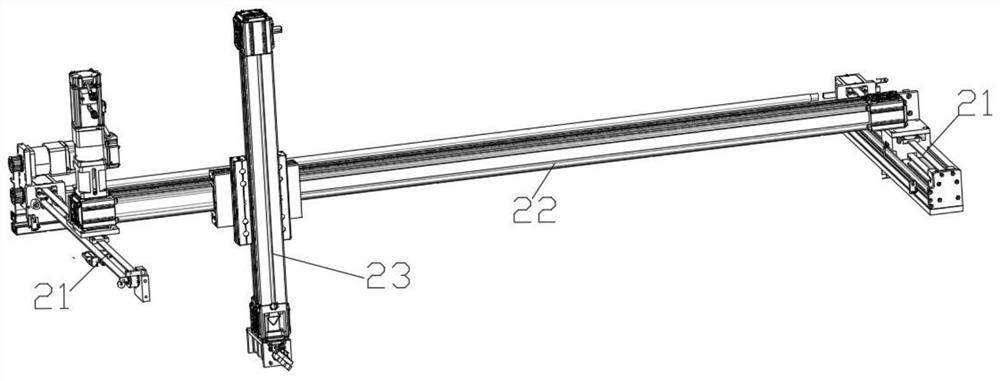

[0035] like figure 1 A buoy machine, including a rack 1, and a stereo moving mechanism 2 is mounted, a front end fixture and a rear end fixture are mounted on the stereo mobile mechanism 2; the frame 1 is also mounted on The buoy fixing rotating mechanism 8, the buoy machine 4 and the buoy support structure 3.

[0036] The use process is: stereo mobile mechanism 2 drives the front end fixture and the rear end fixture, wherein the front end fixture is used for taking and material, and the rear end fixture is moved for the sheet and discharge. This makes each front end clamp, and then move it to the ink cartridge, the rear end fixture can be performed, and the lower end clamp can be immediately performed immediately. At the same time, the stereo mobile mechanism 2 drives the front end fixture and the rear end clamp back to the material, the rear end clamp is discharged, and the front end clip immediately can make the tetrane, and then move to the ink cartridge, in this mobile proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com