Compressor and air conditioner

A technology of compressors and air conditioners, which is applied in the field of compressors, can solve problems such as valve plate breakage and abnormal noise, and achieve the effects of reducing impact force, improving reliability, and reducing opening height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

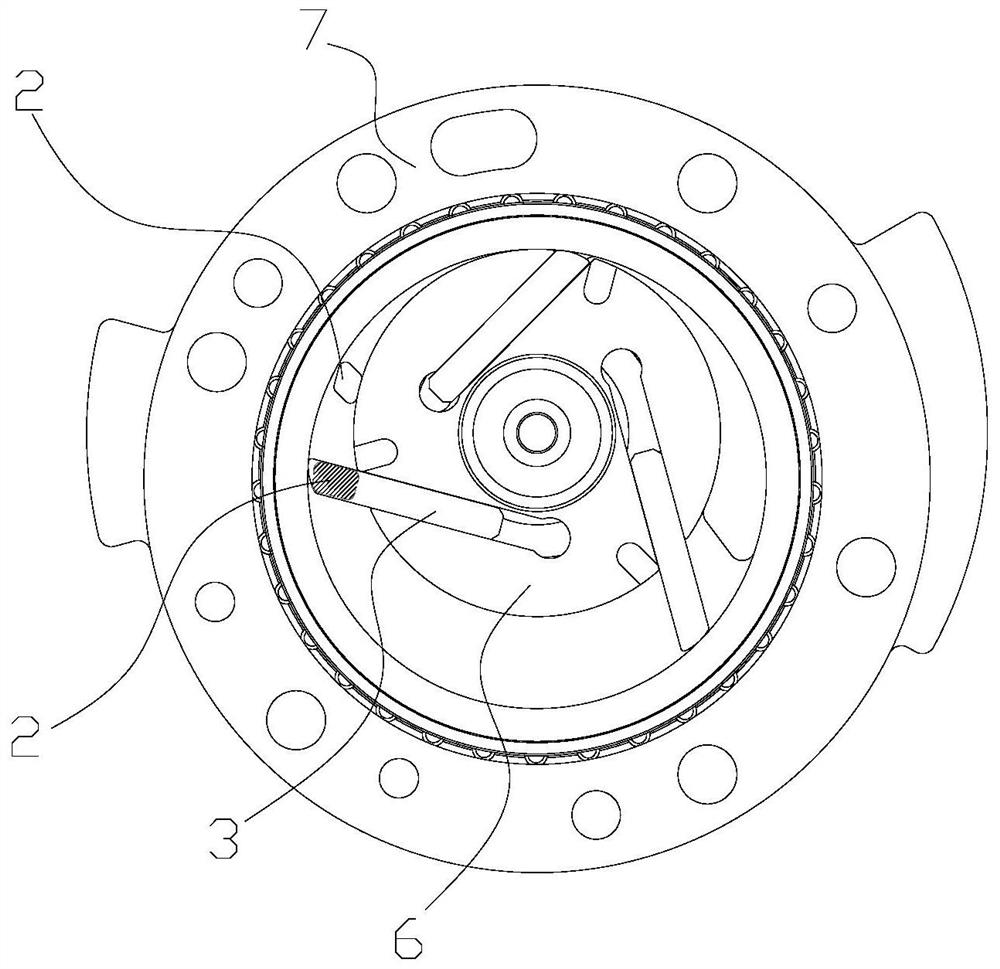

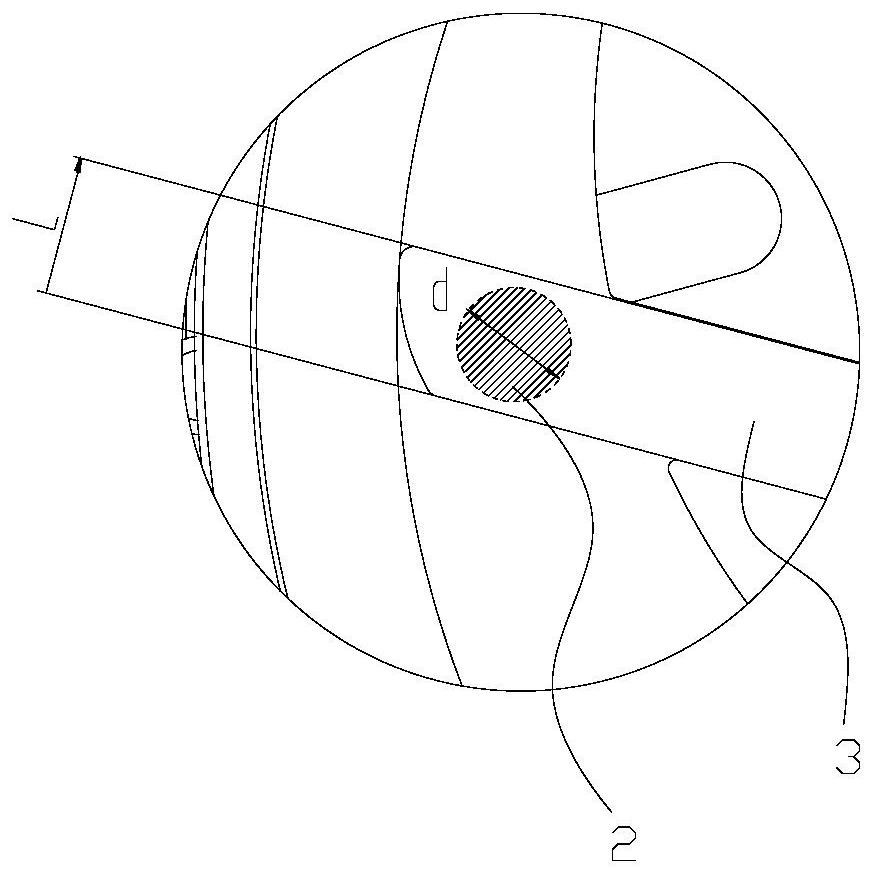

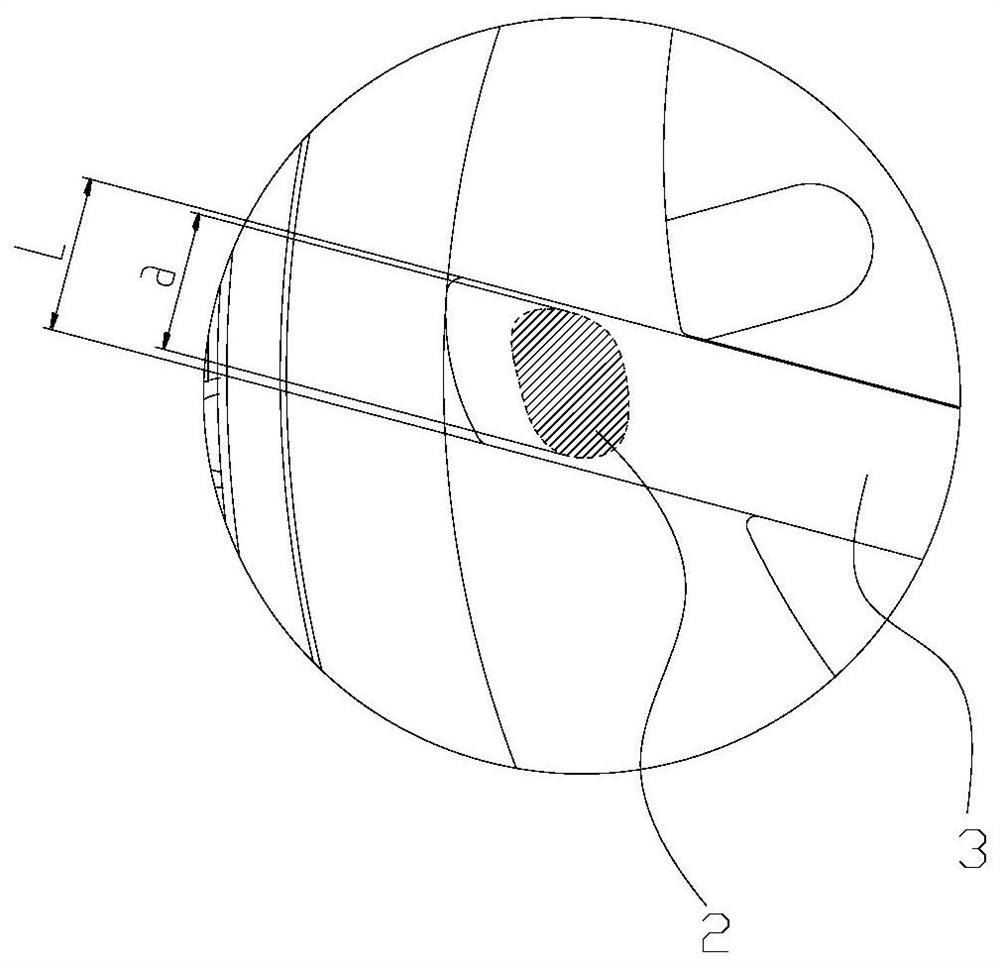

[0031] see in conjunction Figure 1 to Figure 9 As shown, according to the embodiment of the present application, the compressor includes a pump body assembly, the pump body assembly includes a valve seat 1, and at least two exhaust ports 2 are arranged on the valve seat 1, and the areas of the exhaust ports 2 are sequentially S1 and S2 ,...,Sn, the unit is mm 2 , the displacement of the compressor is V, and the unit is mm 3 , where V / [1000*(S1+S2+...+Sn)]≤1.5.

[0032] Generally speaking, the smaller the exhaust velocity of the exhaust port 2, the smaller the impact force of the air flow on the head of the valve plate 4, and the smaller the force required to overcome the stiffness of the valve plate 4 itself. Within the limited range, the opening height of the valve plate 4 is smaller. Based on this characteristic, the compressor in the embodiment of the present application limits the overall discharge speed of the compressor through the relationship between the displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com