Burr removing equipment for junction box production

A technology for removing burrs and junction boxes, which is applied in the field of burr removal equipment for junction box production. It can solve the problems of low work efficiency, time-consuming and labor-intensive work, and scraper damage to the surface of the junction box. It achieves convenient operation, improved work efficiency, and accurate rotation position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

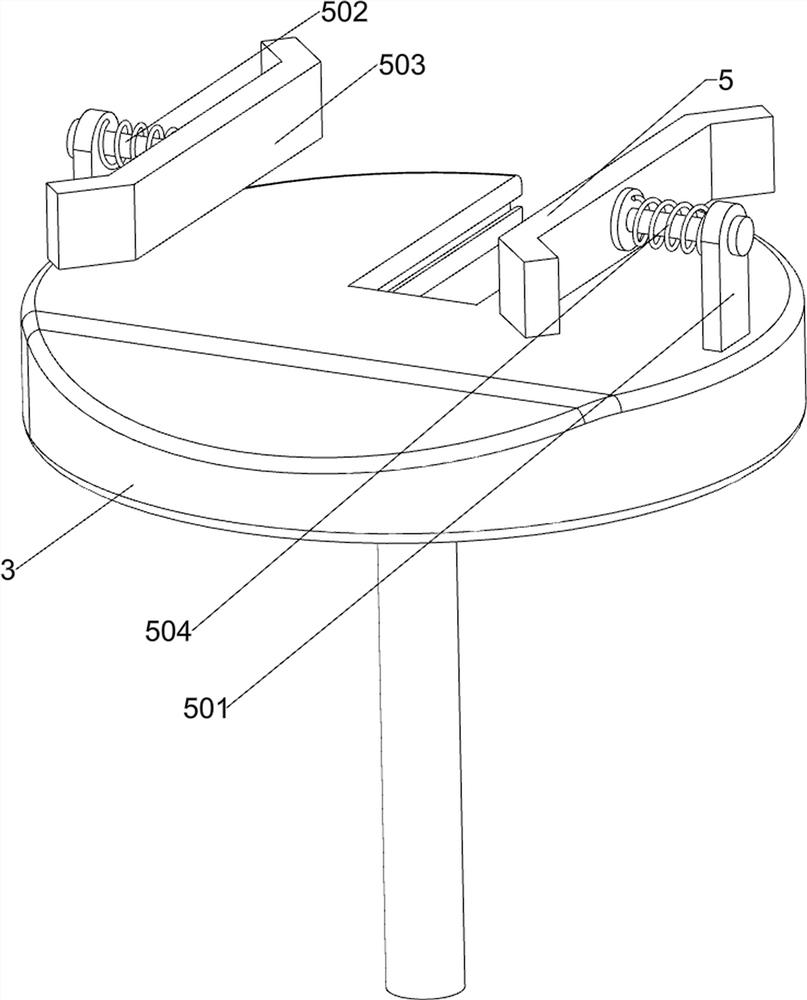

[0032] A deburring equipment for junction box production, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a base 1, a first bracket 2, a storage rack 3, a scraper assembly 4 and a clamping assembly 5. The upper left side of the base 1 is provided with a first bracket 2, and the upper rear side of the first bracket 2 is rotated. The rack 3 has a scraping assembly 4 on the upper middle right side of the base 1, and a clamping assembly 5 on the top of the rack 3.

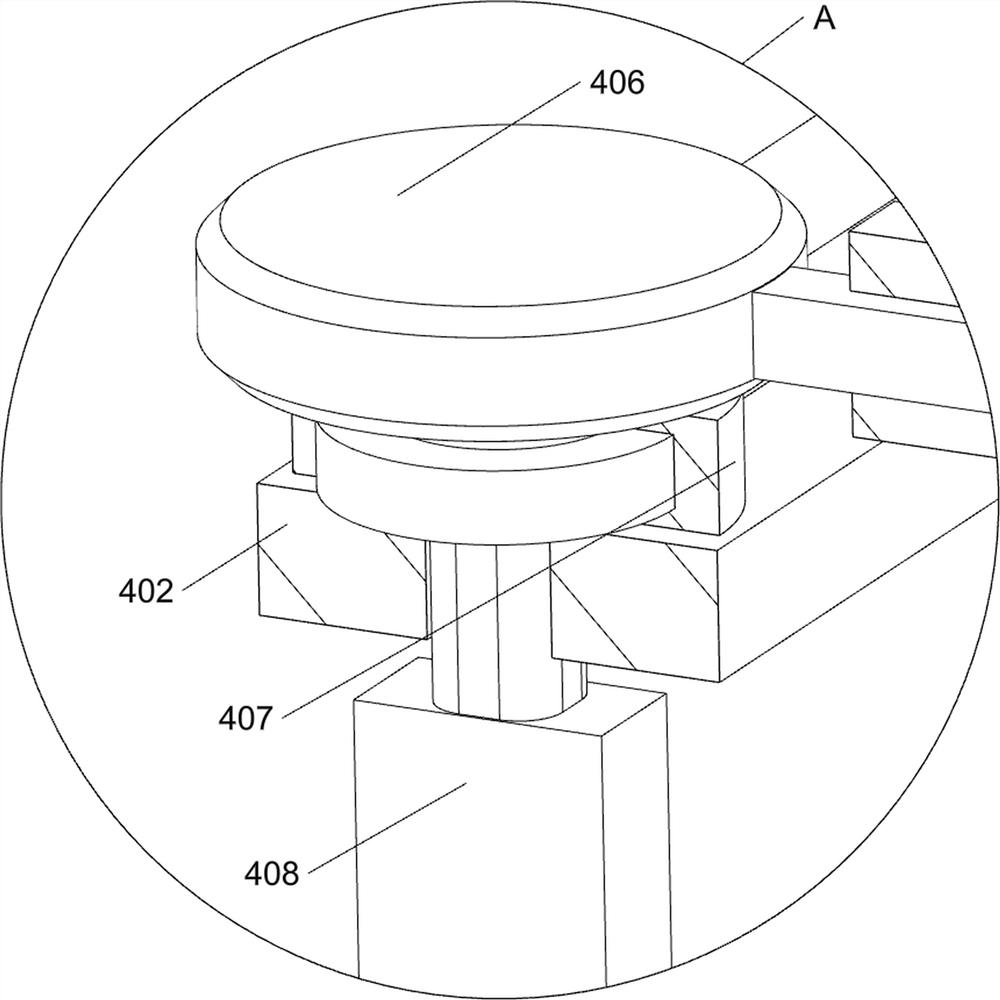

[0033]The scraping assembly 4 includes a first guide rail 401, a second guide rail 402, a first slide block 403, a first connecting rod 404, a first spring 405, a first support frame 406, a first sliding sleeve 407 and a chamfering knife 408, a base 1 There is a first guide rail 401 in the middle of the upper right side, a second guide rail 402 is provided on the top rear side of the first guide rail 401, a first slider 403 is provided on the front side of the upper part of t...

Embodiment 2

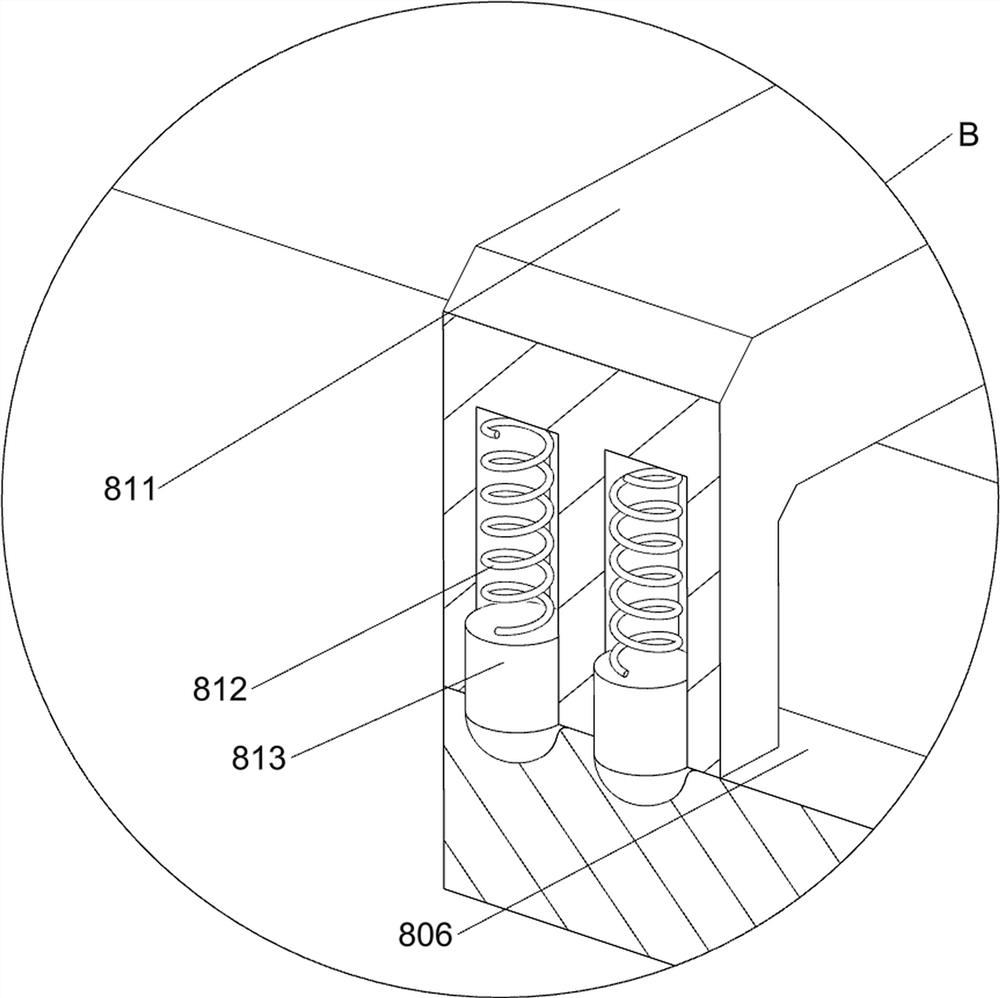

[0037] On the basis of Example 1, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a transmission assembly 6 is also included. The transmission assembly 6 includes a motor 601, a first transmission wheel 602, a support plate 603, a first support rod 604, a second transmission wheel 605, a belt 606, a first contact plate 607 and a first contact plate 607. A movable plate 608, the right rear side on the base 1 is provided with a motor 601, the output shaft of the motor 601 is provided with a first transmission wheel 602, the right front side on the base 1 is provided with a support plate 603, and the left side of the support plate 603 top is rotated. There is a first support rod 604, a second transmission wheel 605 is arranged on the left side of the first support rod 604, a belt 606 is wound between the first transmission wheel 602 and the second transmission wheel 605, and a first contact plate 607 is arranged on the belt 606 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com