Patents

Literature

38results about How to "Precise rotational position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

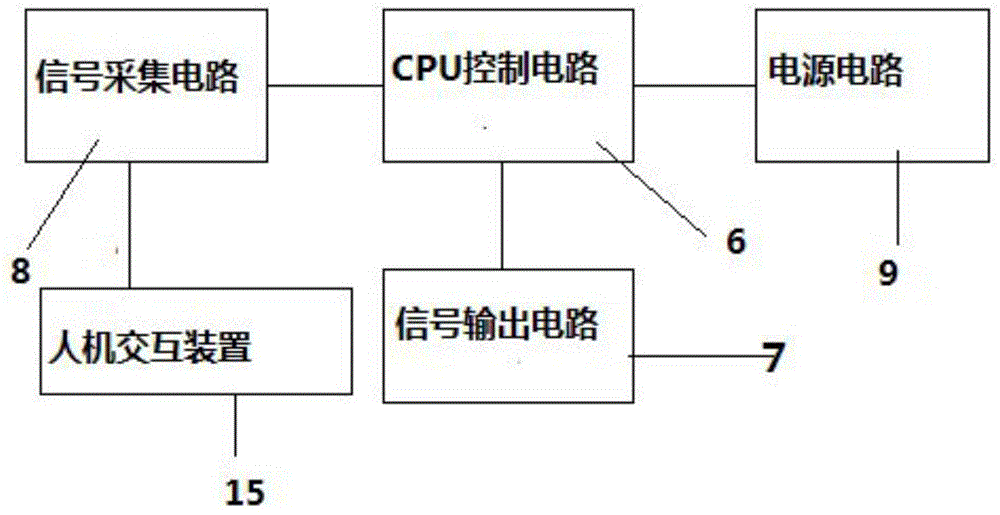

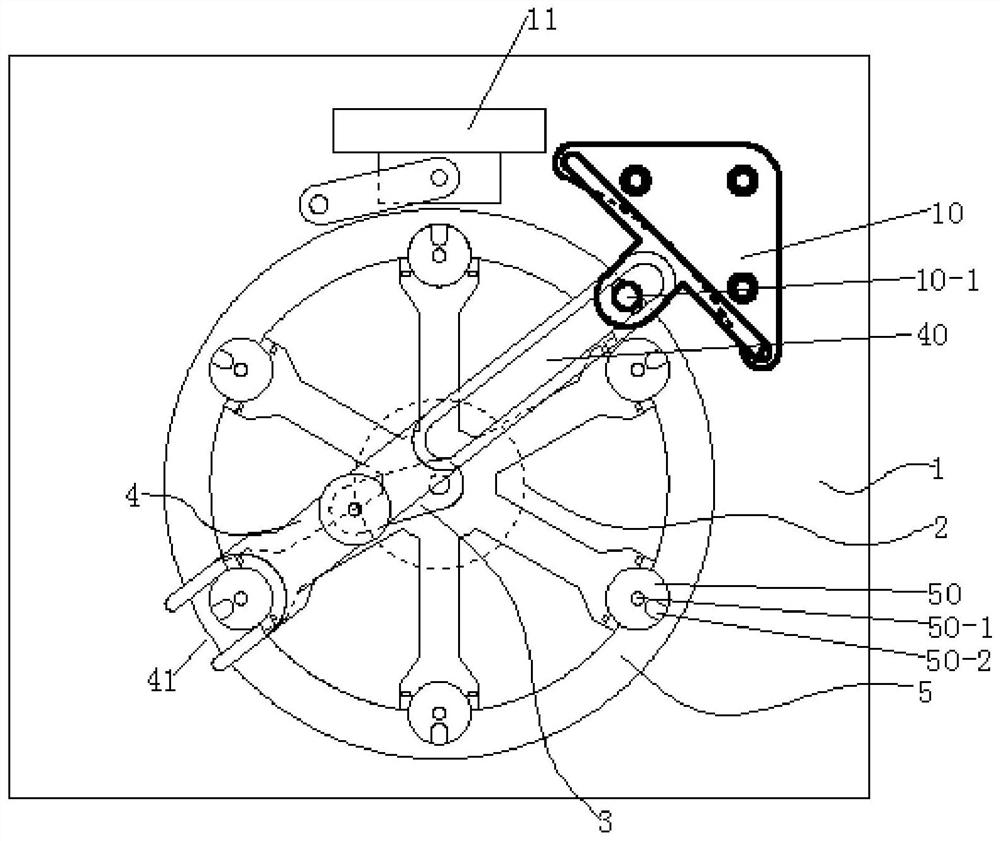

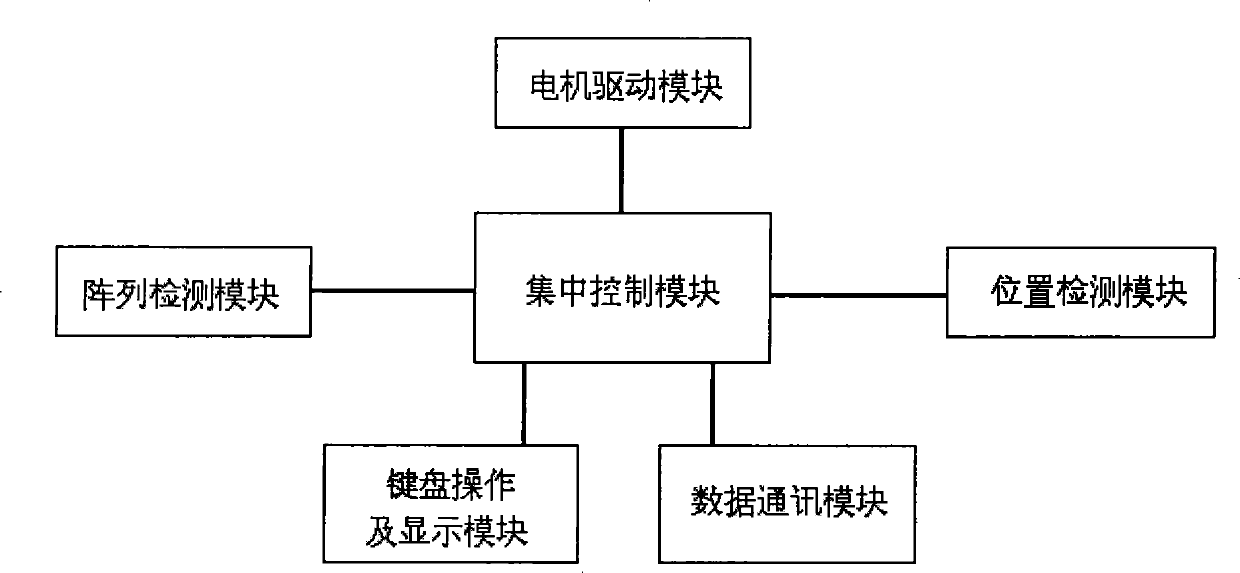

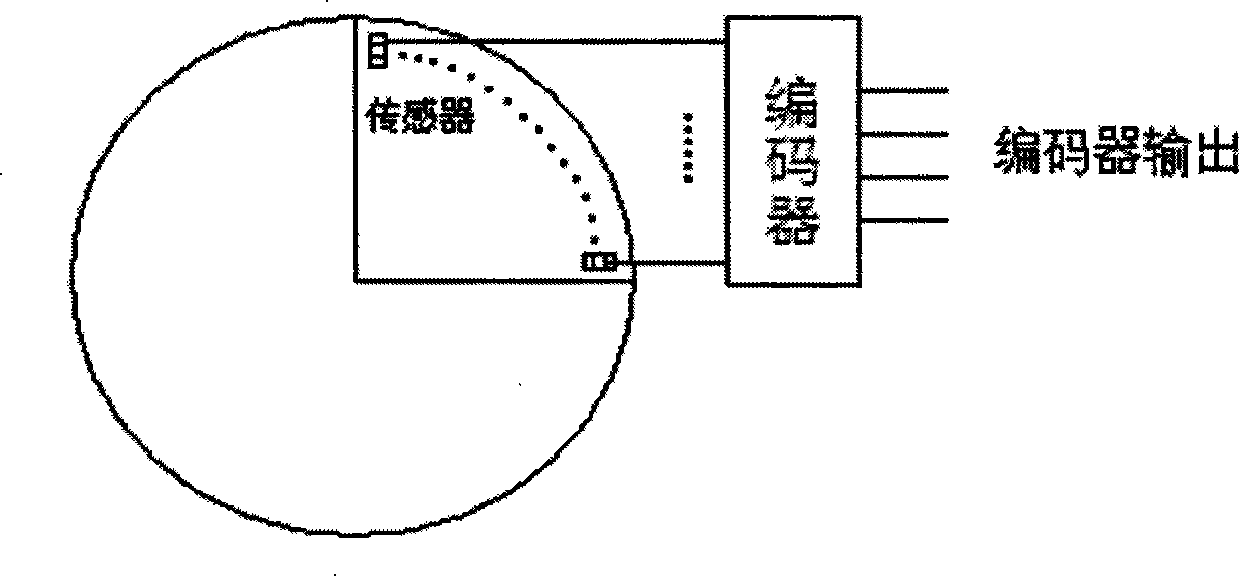

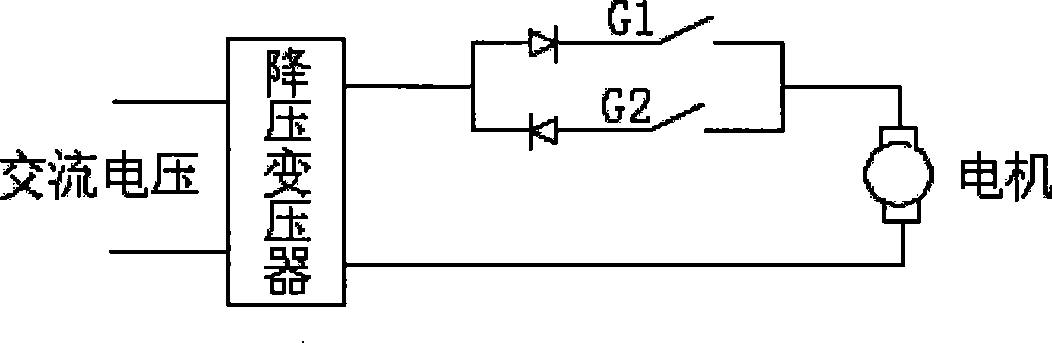

Method and device for tracking control of solar electrical energy generation

InactiveCN101592969AIncrease energy outputImprove photoelectric conversion efficiencyPhotovoltaic supportsControl using feedbackLocation detectionAutomatic control

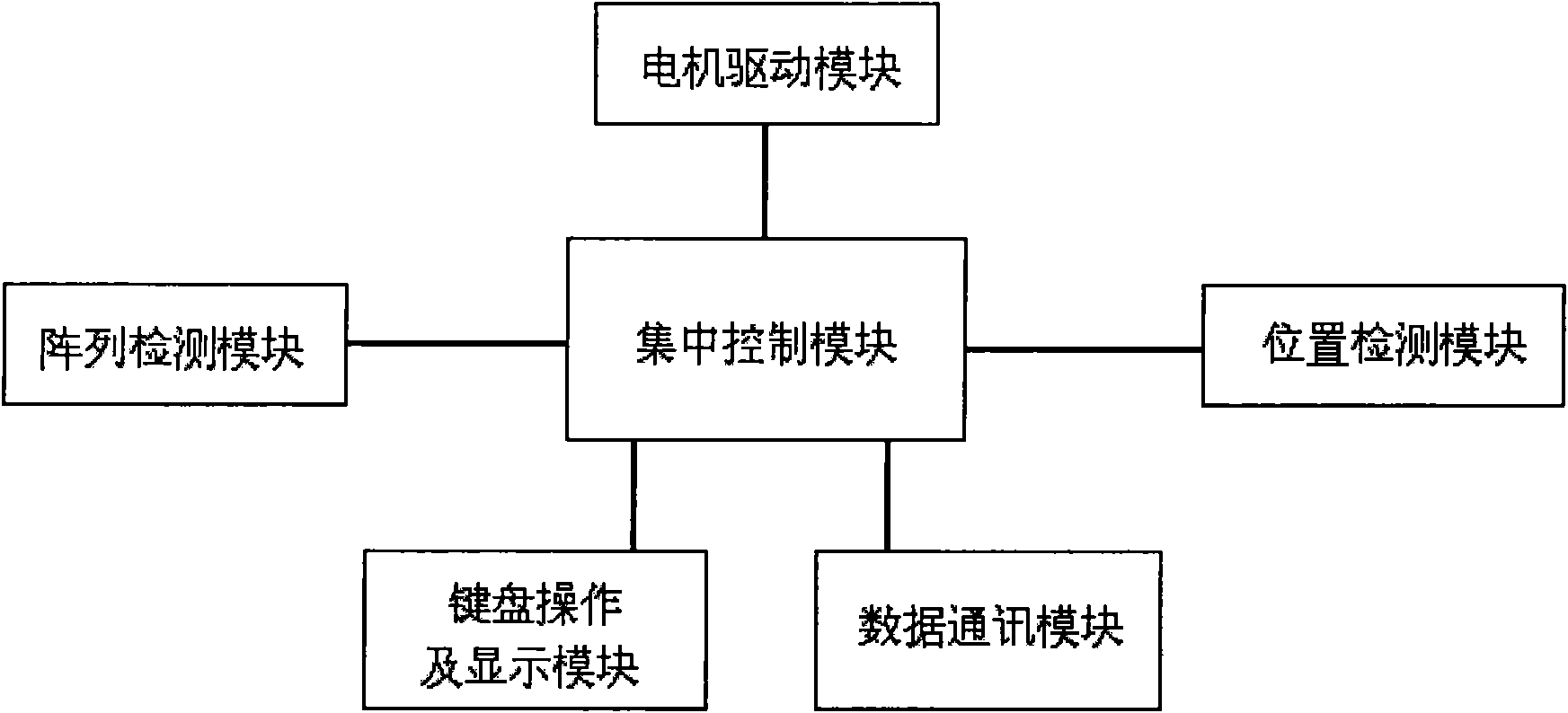

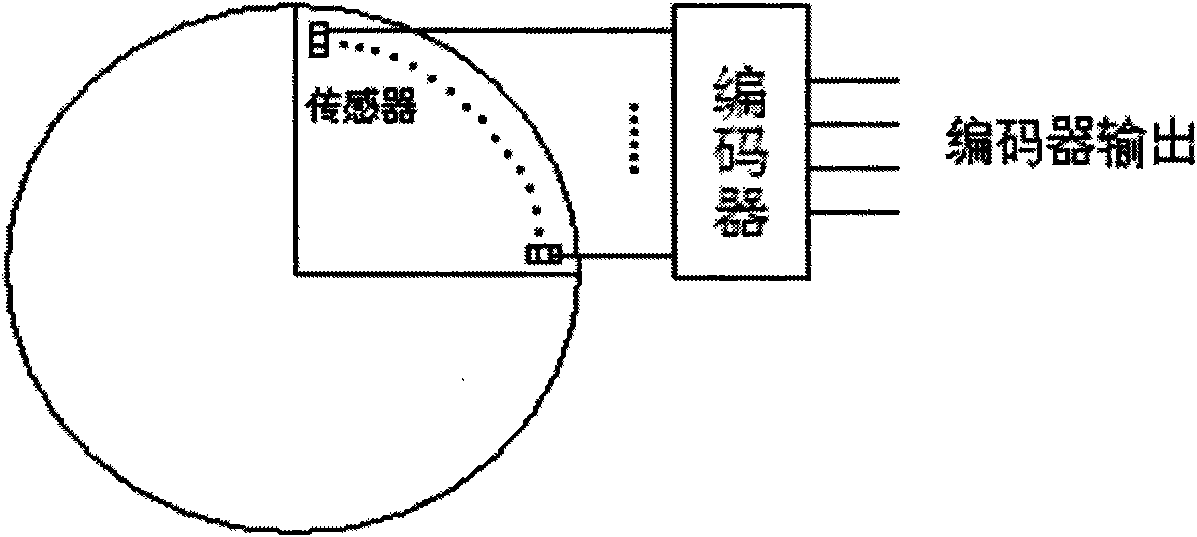

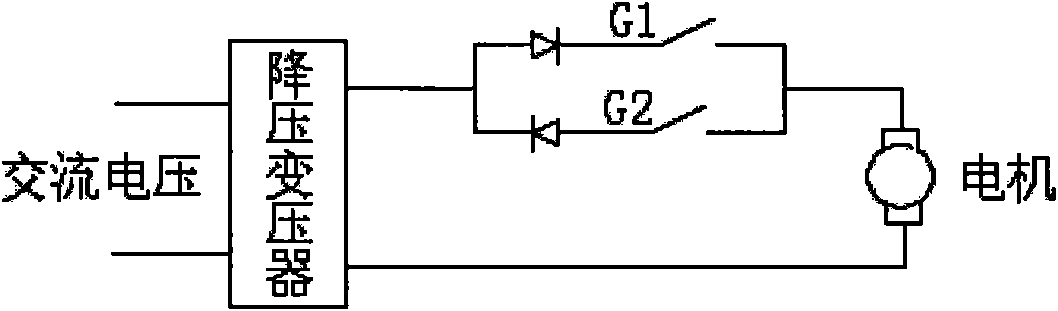

The invention discloses a method and a device for tracking control of solar electrical energy generation. The method comprises the following steps: automatically selecting a maximum power tracking mode or a timed tracking mode according to the level of the real-time output power of a solar battery; when the timed tracking mode is run, controlling tracking according to the current time and the detected current position signal of a solar panel; and when the maximum power tracking mode is run, determining the tracking direction of a mechanical structure according to the changing condition of the output power of the solar battery. The device comprises a centralized control module, a position detecting module for detecting the actual rotating position of the solar panel, and an array detecting module for detecting the real-time output power of the solar battery. The invention has the advantages of simple and convenient operation, accurate rotating position, realization of automatic control, simple structure, high detecting accuracy and low cost.

Owner:SHENZHEN NENGLIAN ELECTRONICS +1

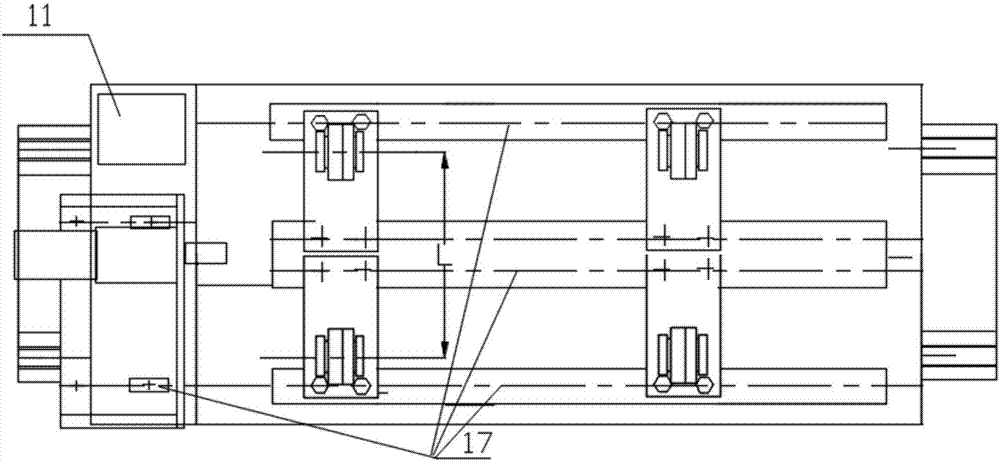

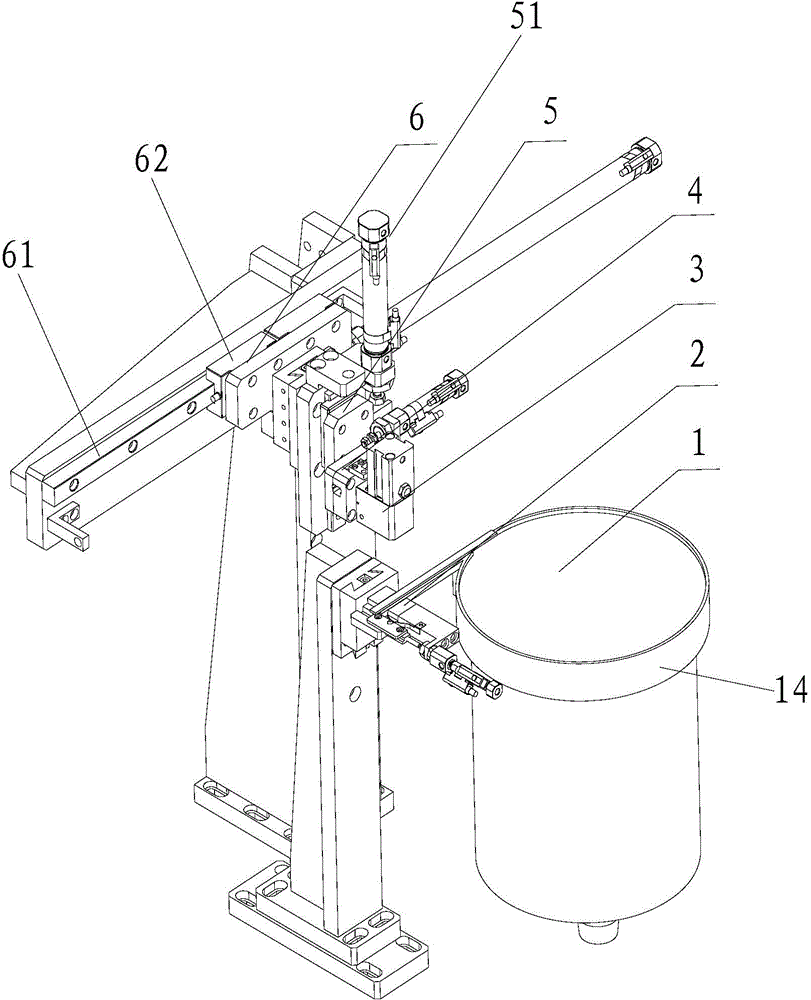

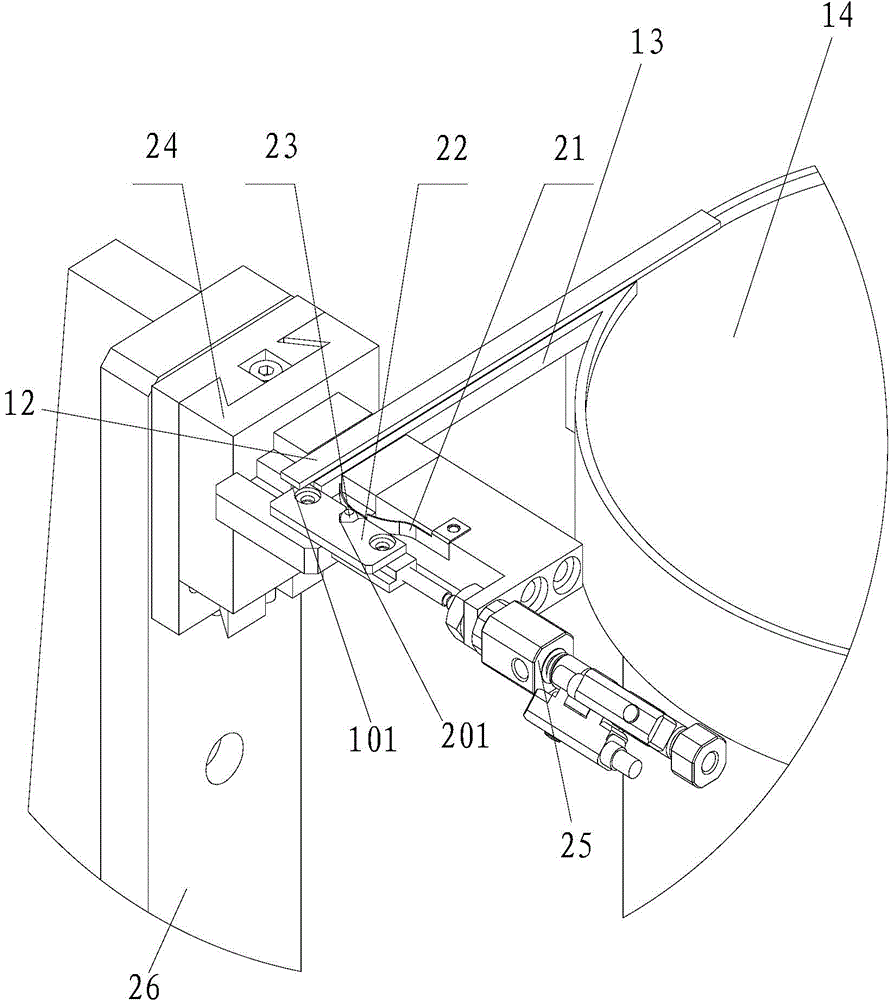

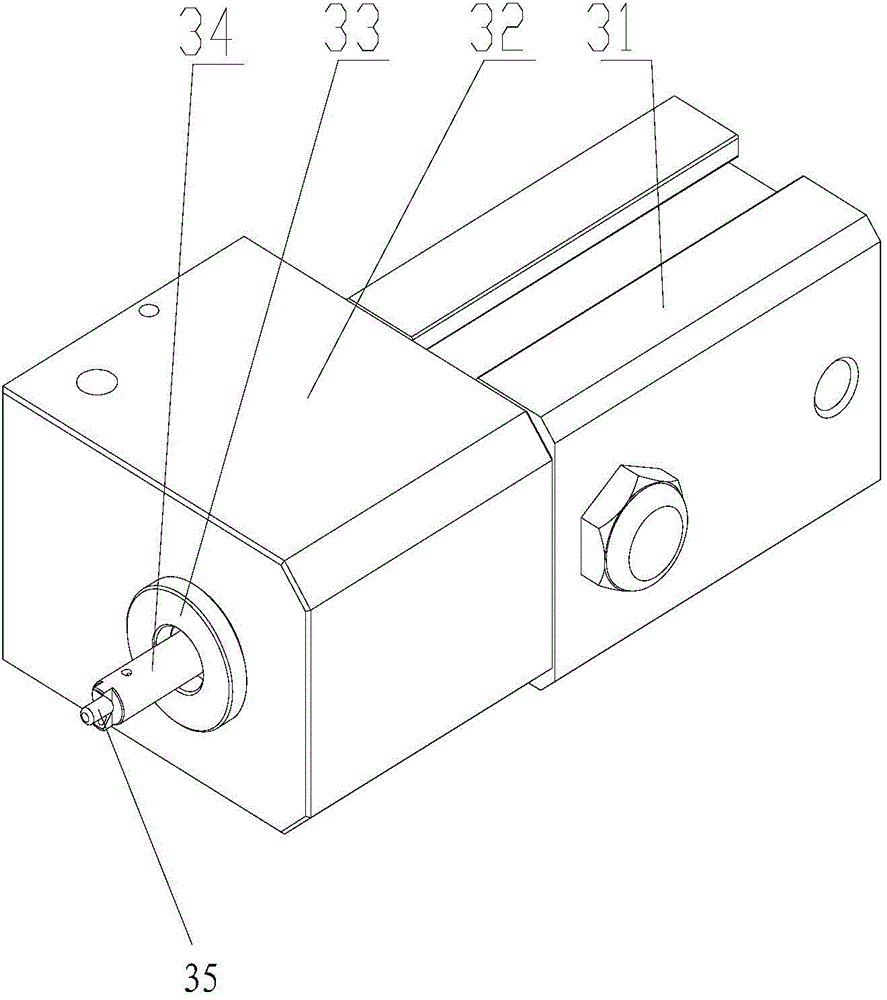

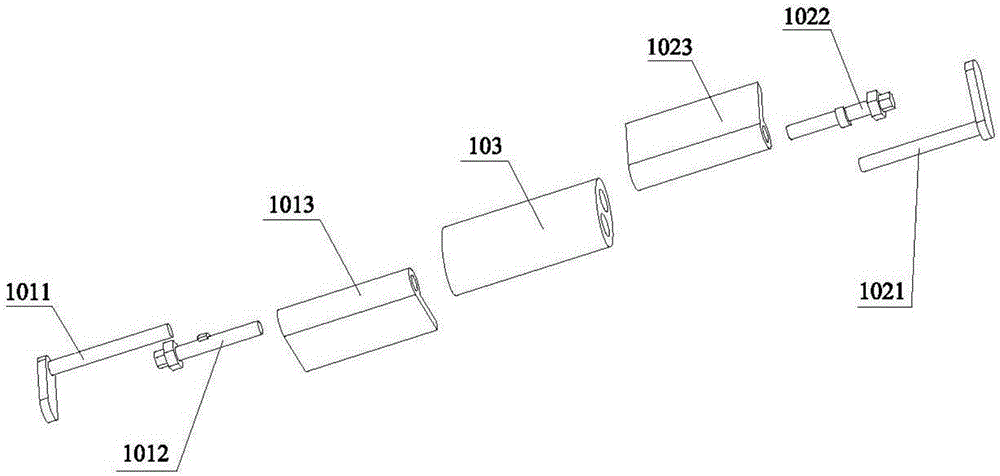

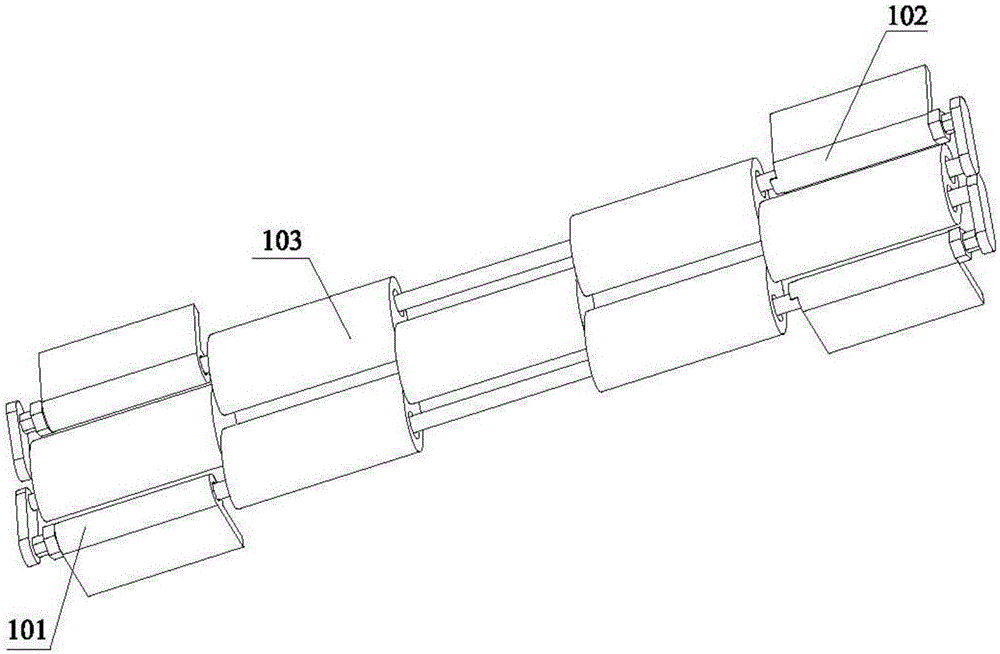

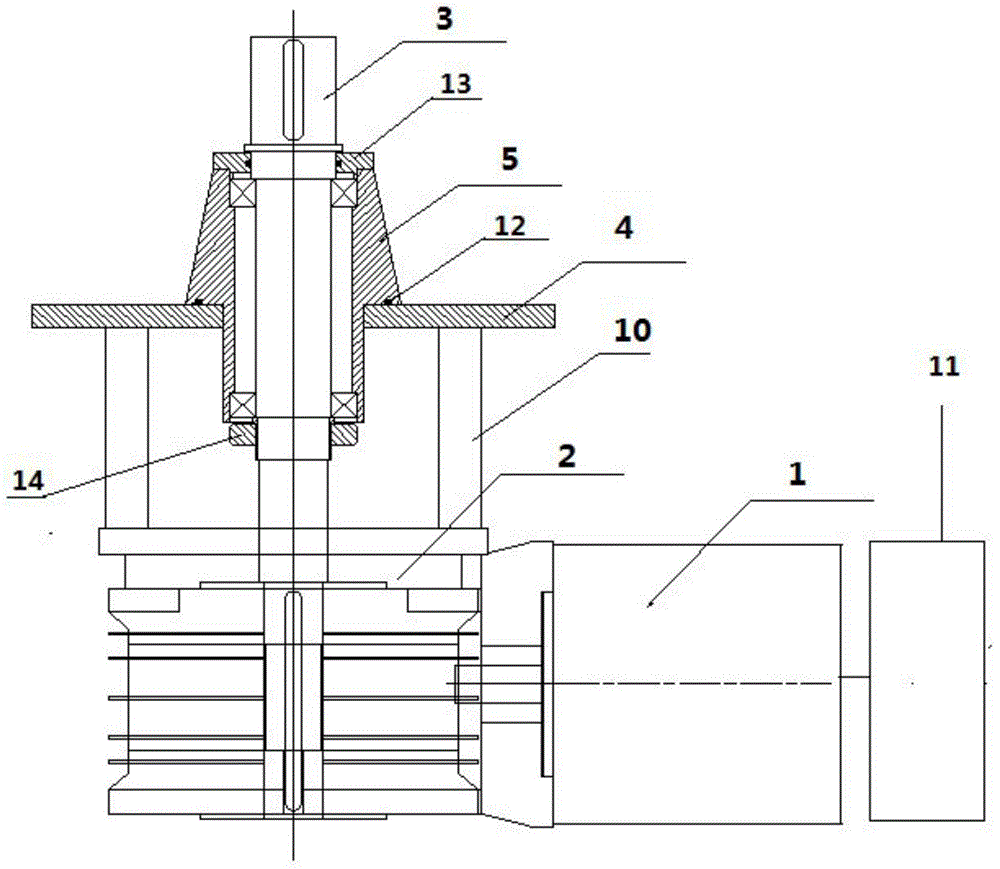

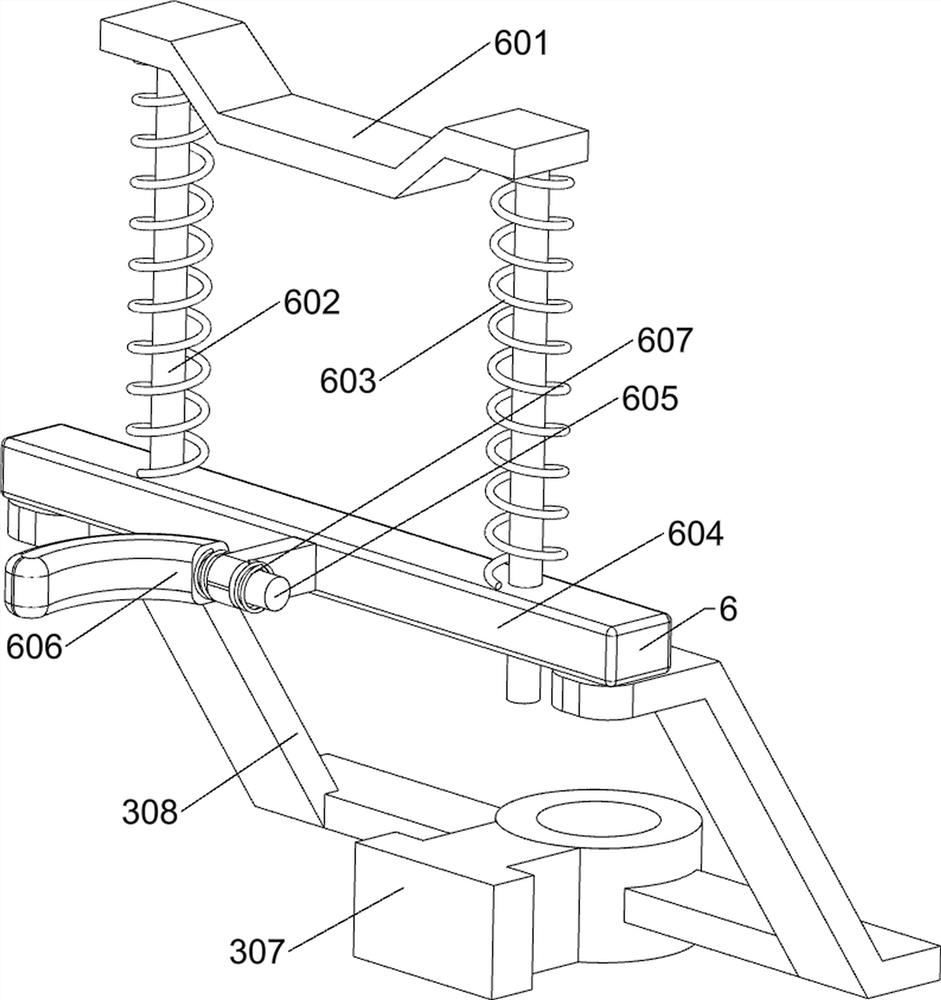

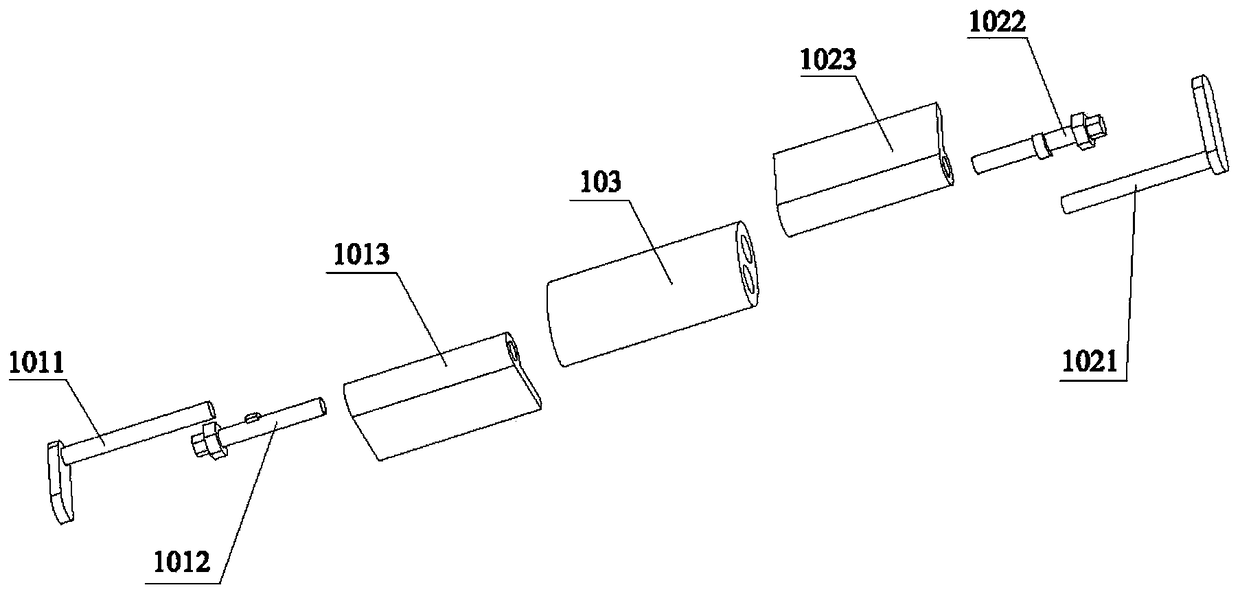

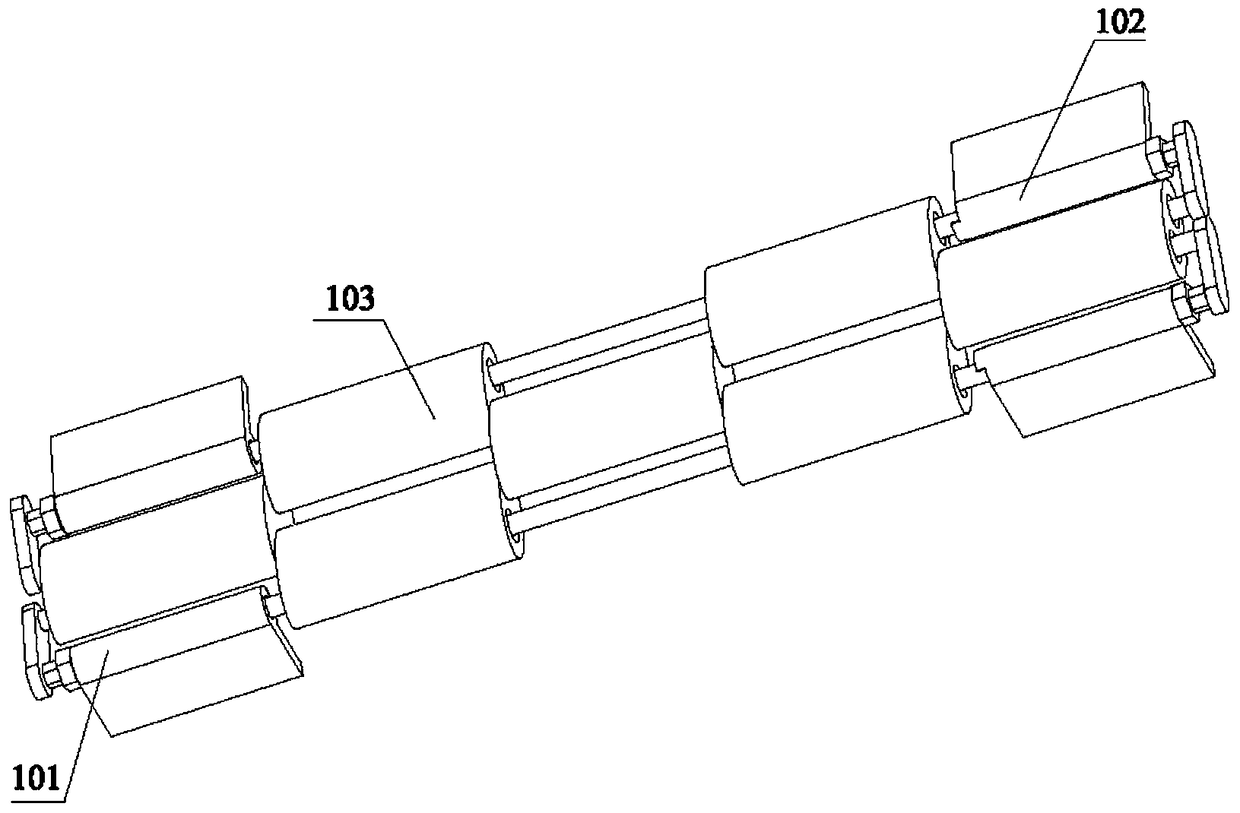

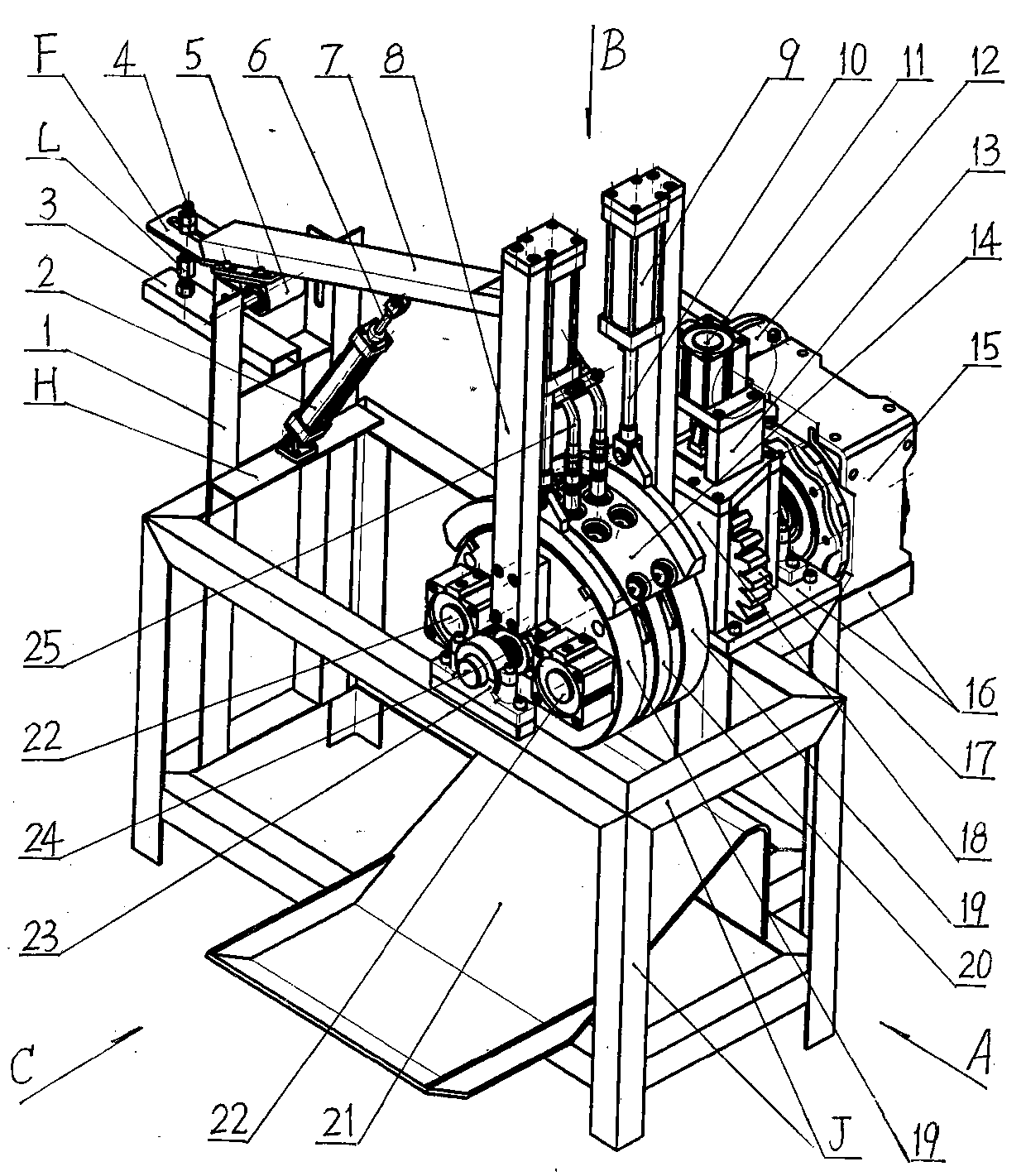

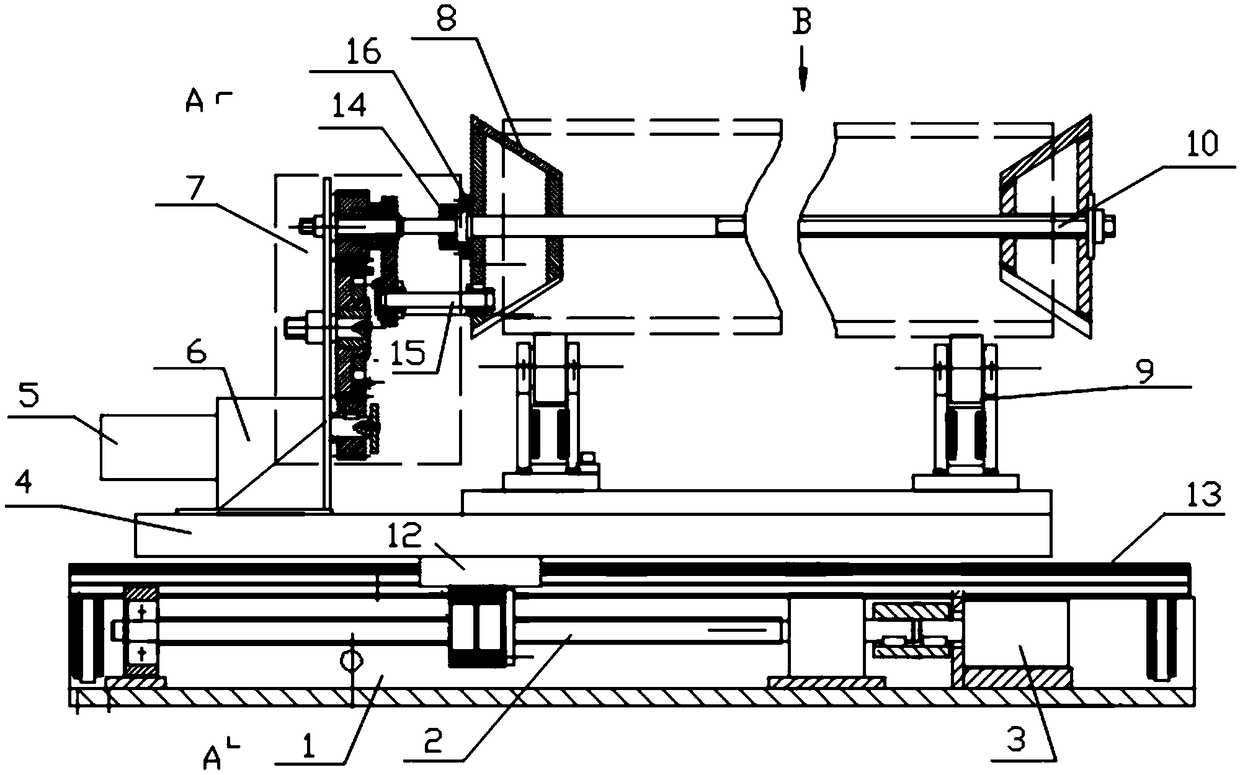

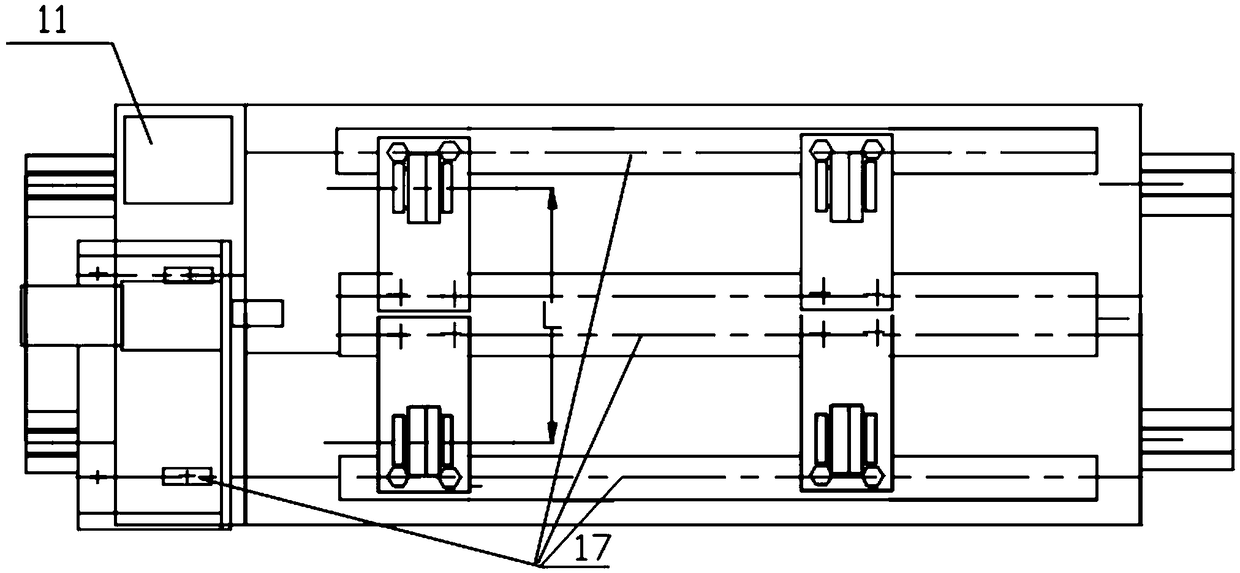

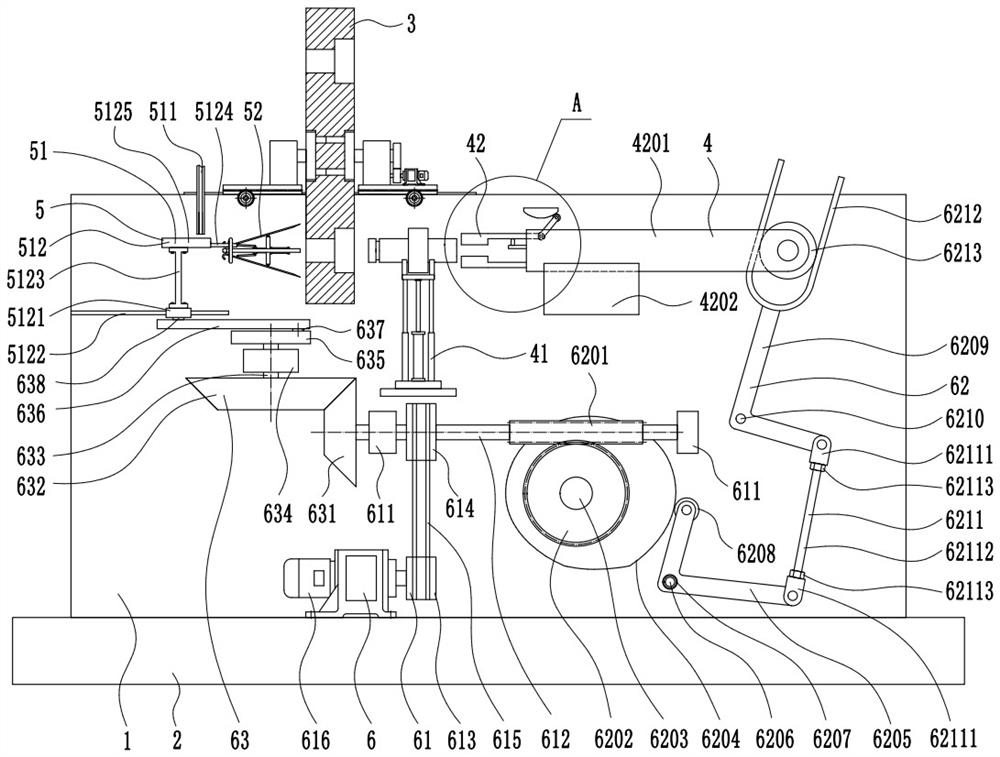

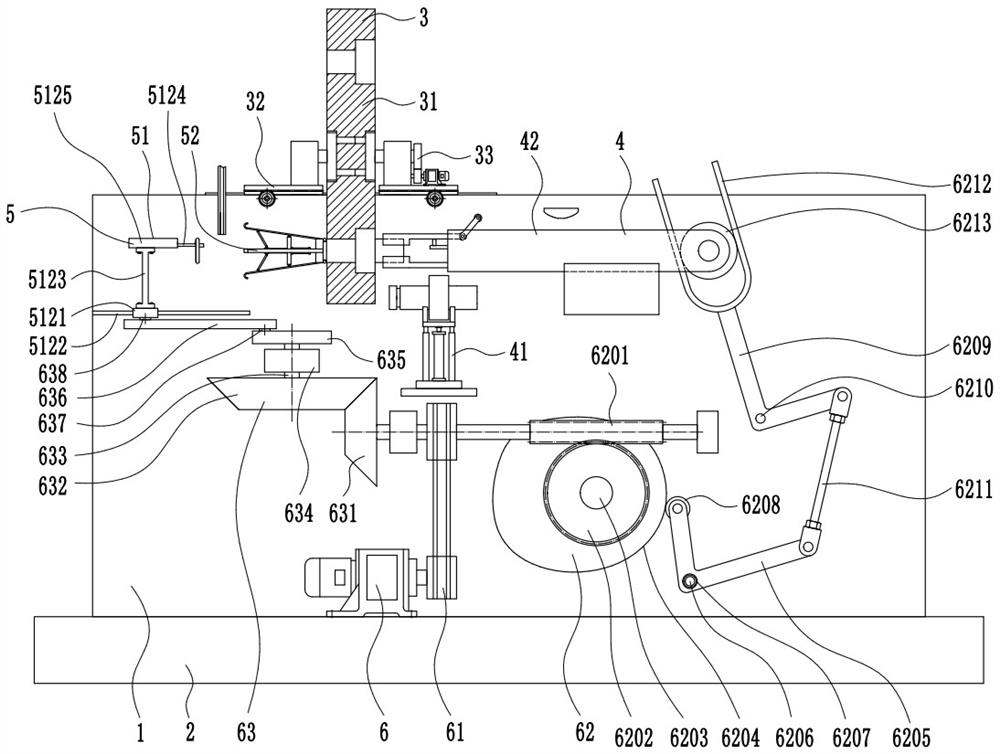

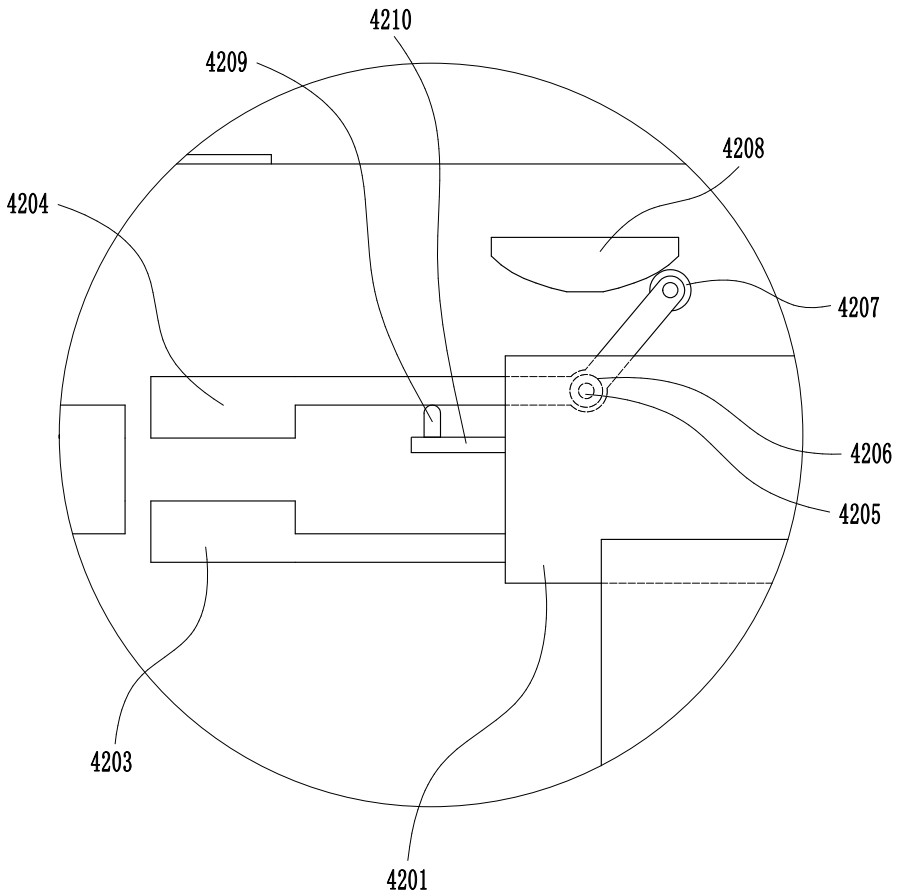

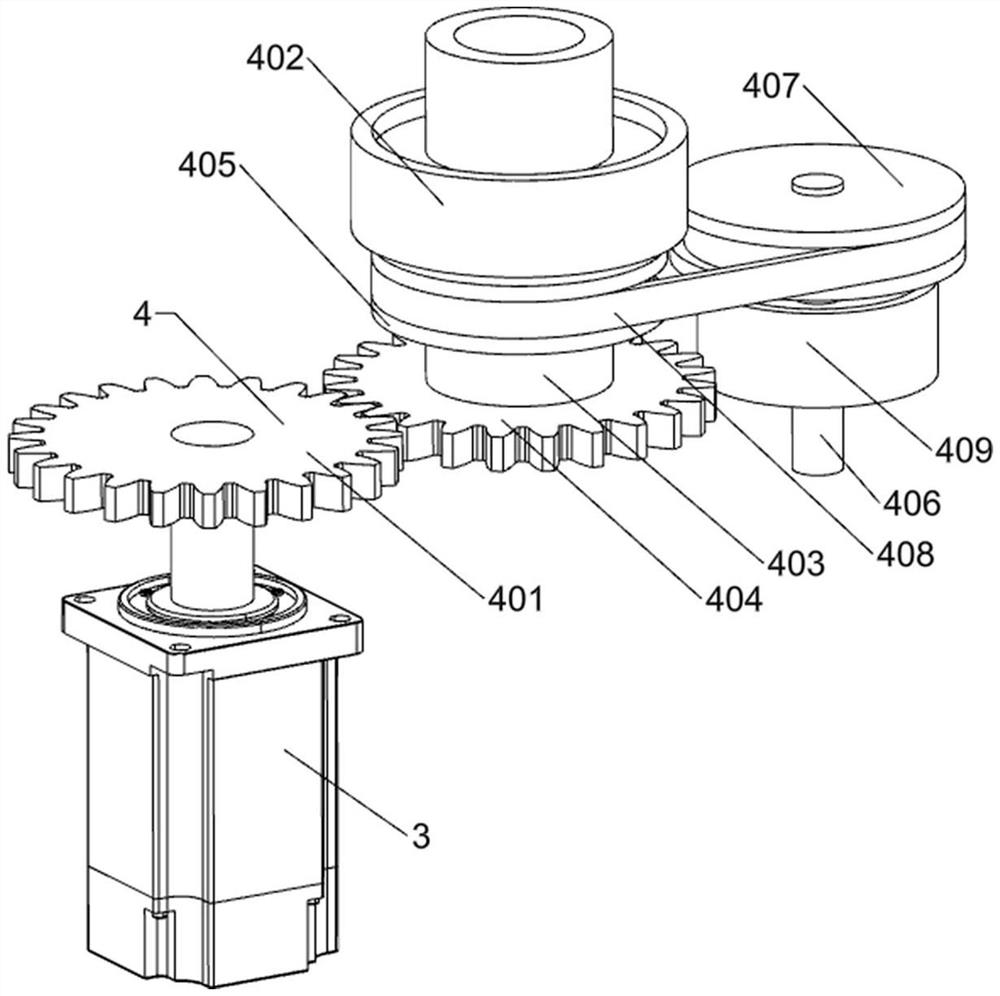

Automated drilling device for pipes of multiple specifications

ActiveCN106881472AReduce frictionPrecise rotational positionFeeding apparatusLarge fixed membersFriction reductionRolling resistance

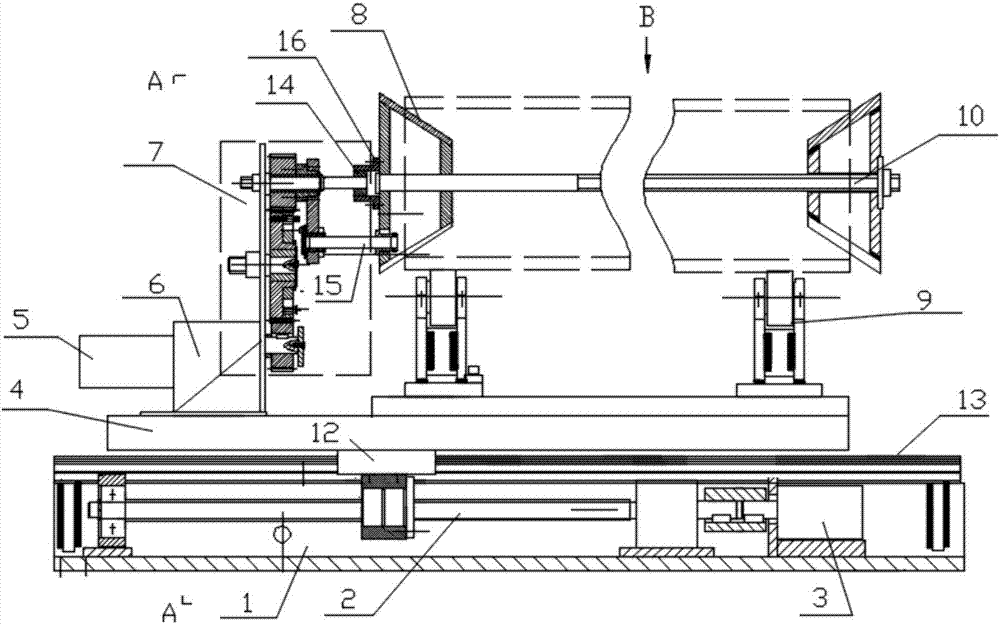

The invention discloses an automated drilling device for pipes of multiple specifications. The automated drilling device comprises a base. The automated drilling device is characterized in that an output shaft of a longitudinal servo motor is linked with a ball screw, and the ball screw is supported by bearings and assembled onto the base; a workbench is further arranged above the base; a rolling guide rail is arranged between the workbench and the base; a mechanism for driving a conical clamp to rotate is arranged on the workbench; and the mechanism comprises support frames, a rotating servo motor, a reducer and a center height adjusting device. The device is provided with multiple adjustment mechanisms, and multiple holes can be drilled in the circumferential faces of the pipes large in length and diameter change range; the pipes move and rotate in the form of rolling friction, friction is reduced, rotation positions and movement positions are precise, and positional precision of all the holes drilled in the pipes is obviously improved; mounting of the pipes is completed one time, and the pipes do not need to be loosened in the intermediate process; and automation is achieved in the whole drilling process, and efficiency is obviously improved.

Owner:江苏三升信电子工程有限公司

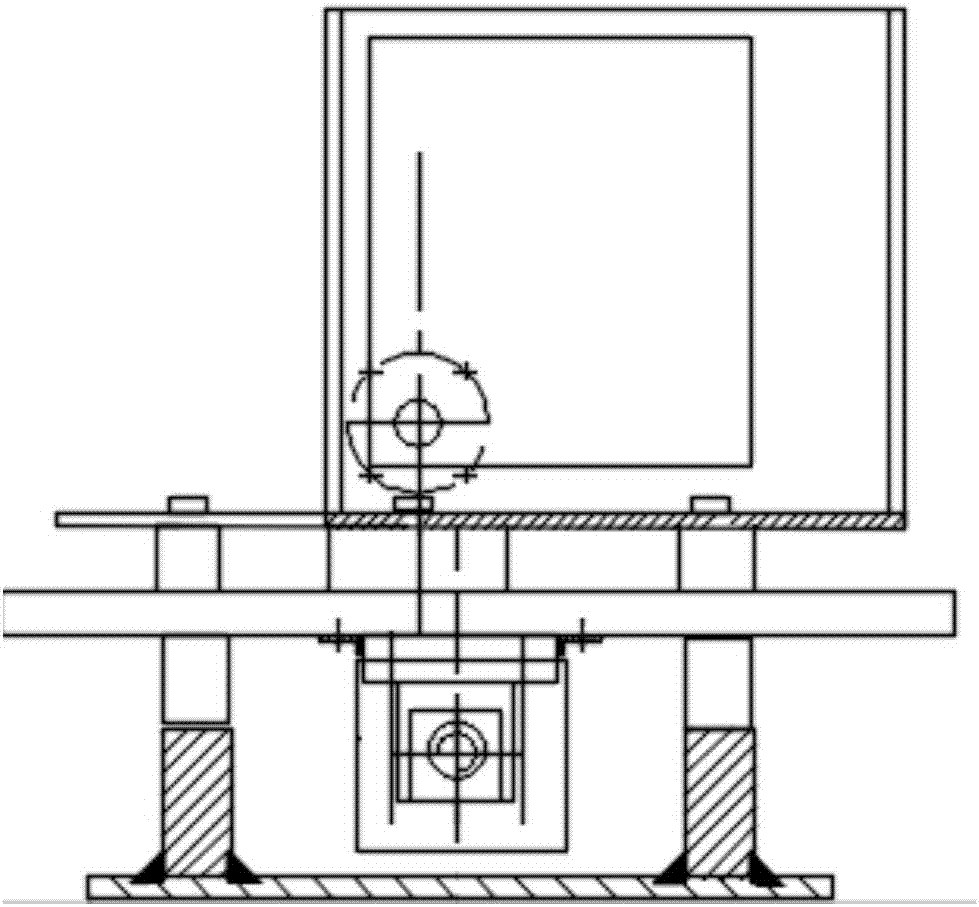

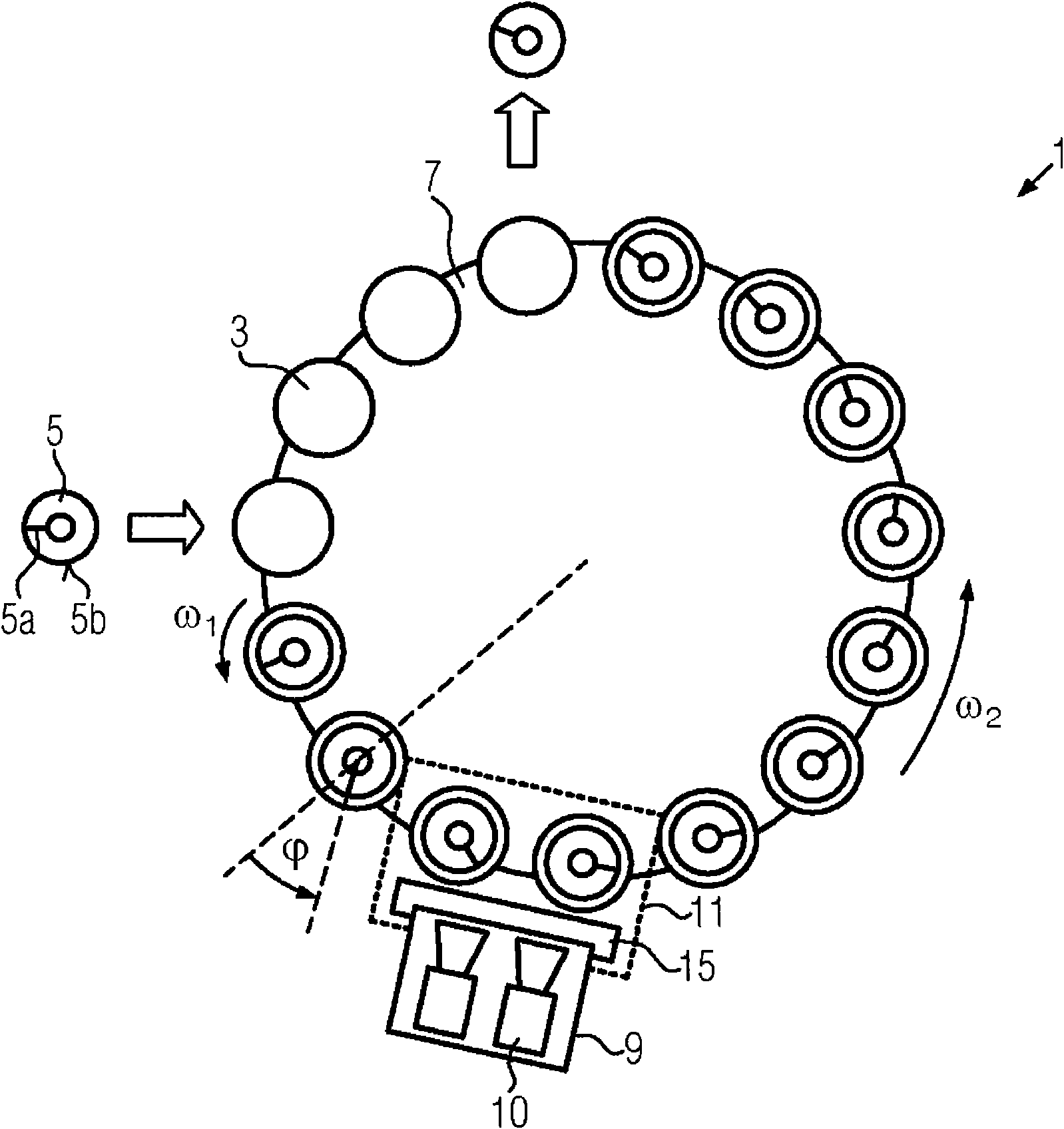

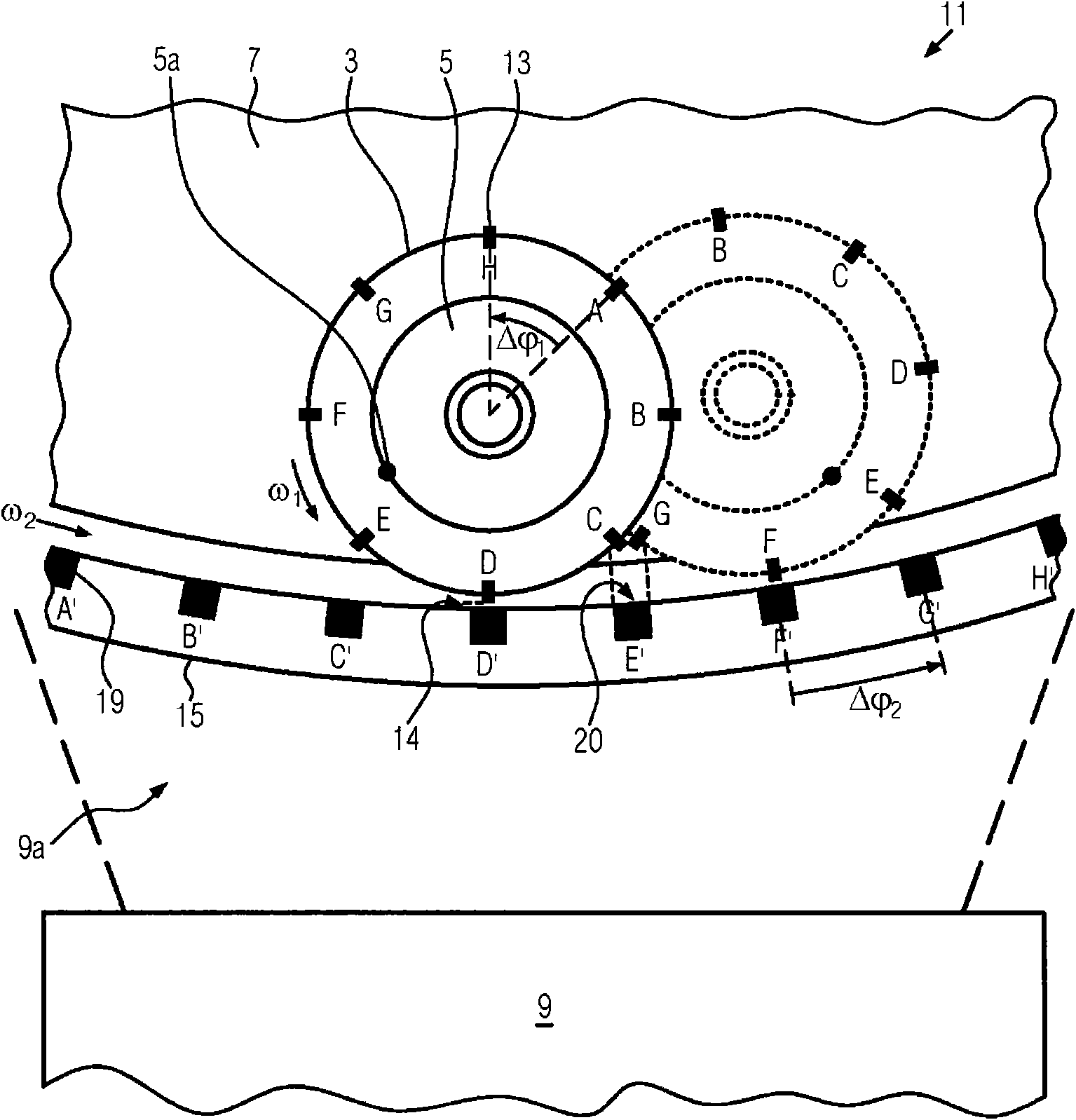

Device and method for aligning containers, in particular bottles, in a labelling machine

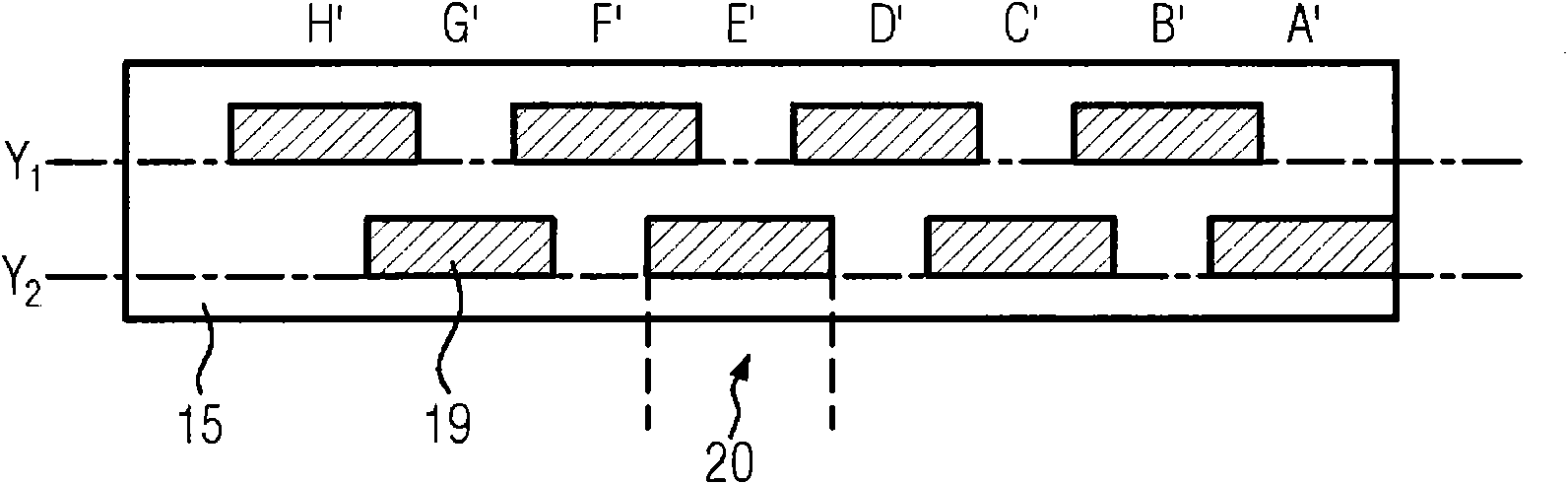

InactiveCN101885393APrecise rotational positionReduce time spentConveyor partsLabelling machinesEngineeringBottle

An apparatus and a method for aligning containers, in particular bottles, in a labeler, the apparatus having rotatable holders for containers to be aligned, and a camera unit for imaging the containers as well as a proximity switch for triggering an imaging function of the camera unit. This allows a precise alignment in combination with a reduced expenditure of time and reduced space requirements.

Owner:KRONES AG

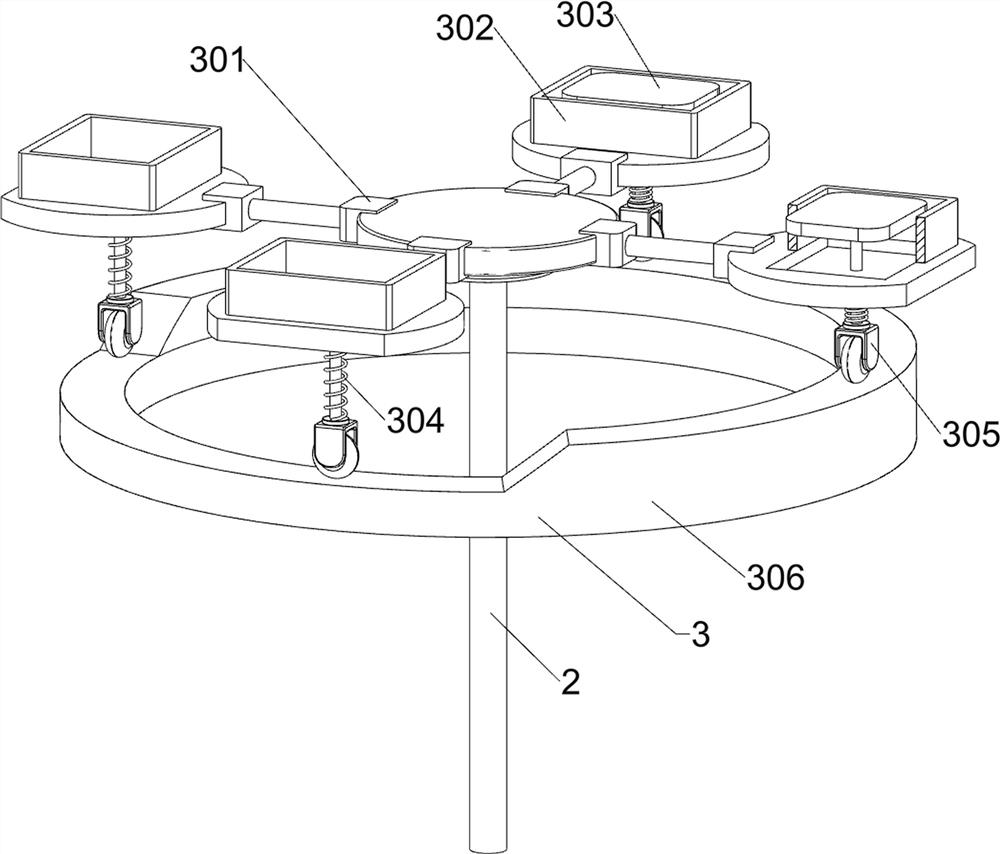

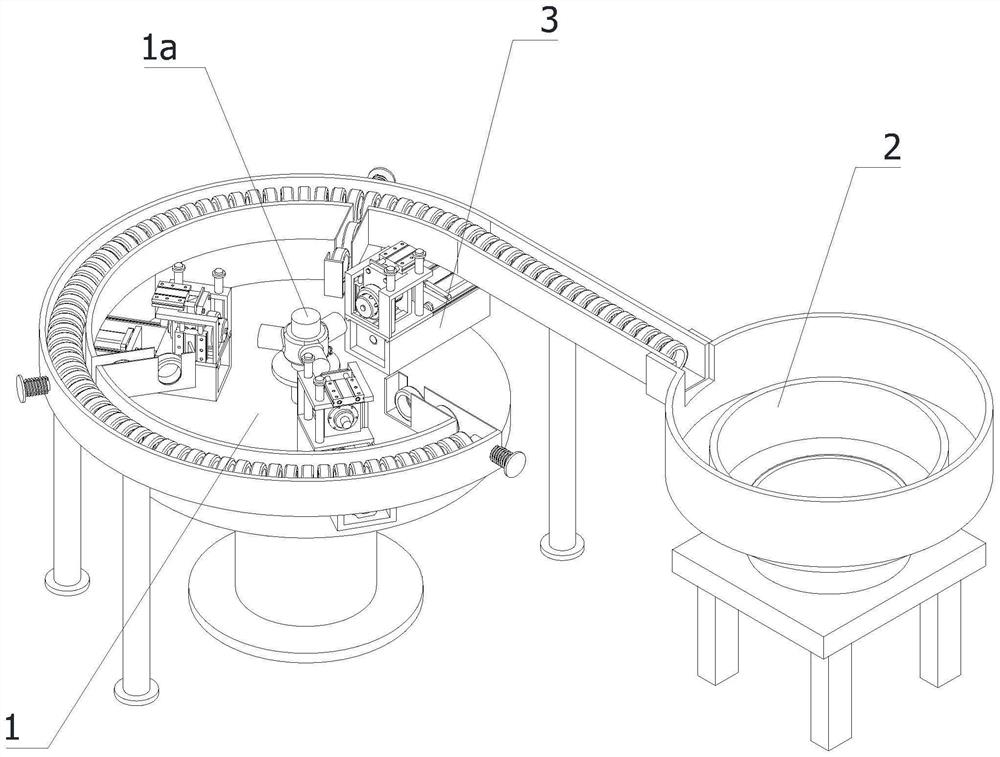

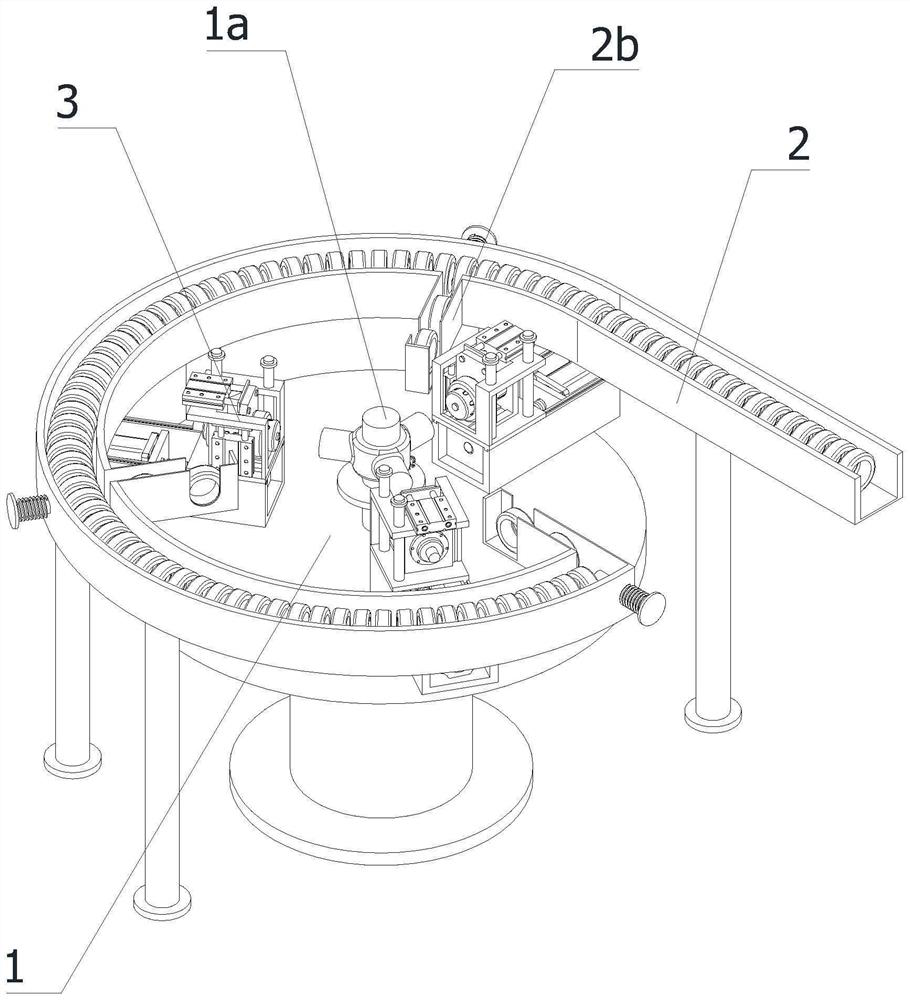

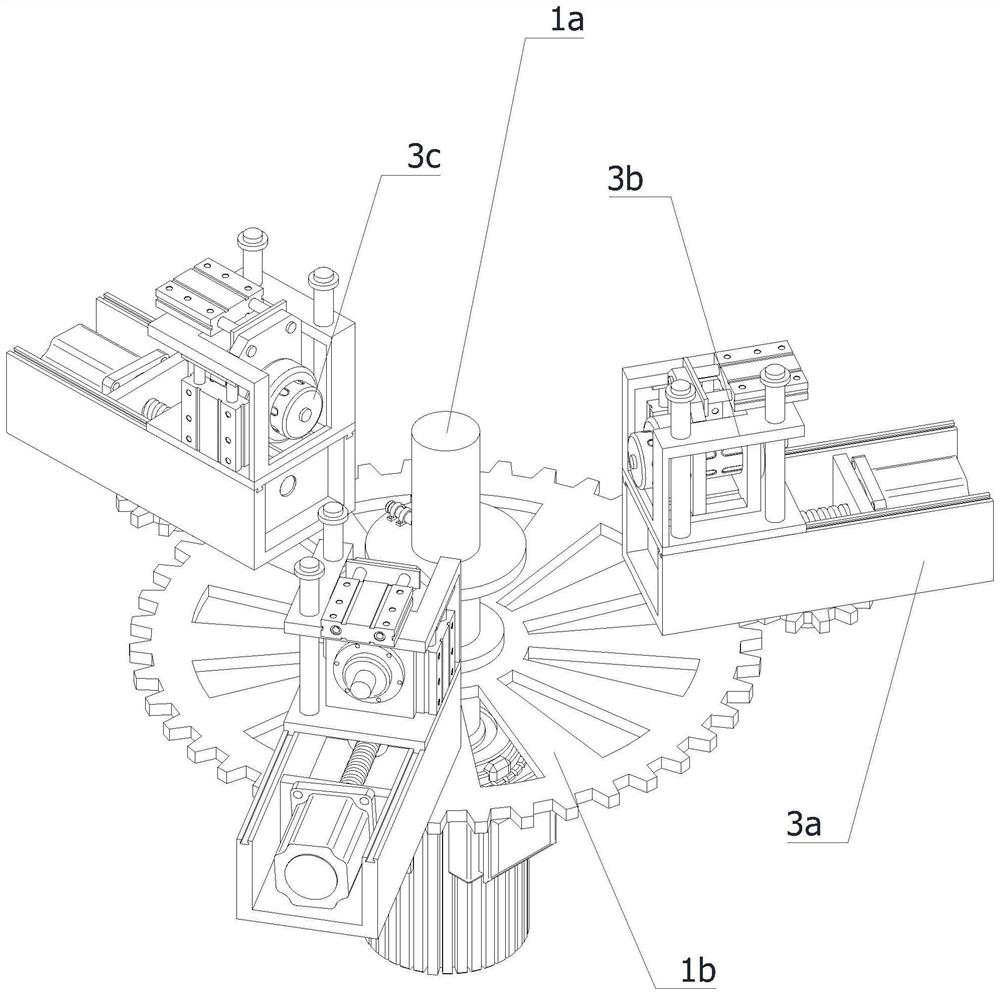

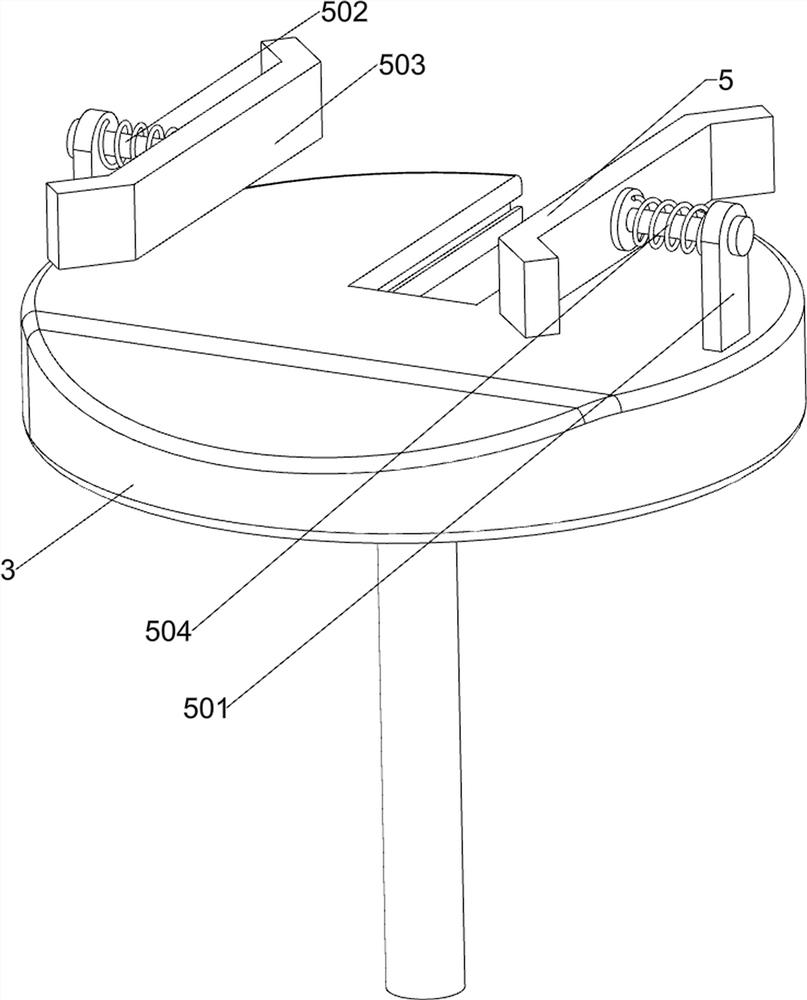

Automatic feeding device of spherical workpiece with axle hole

ActiveCN104475610AHigh degree of automationImprove transmission efficiencyMetal-working feeding devicesPositioning devicesEngineeringAutomation

The invention is applicable to the technical field of workpiece feeding, and discloses an automatic feeding device of the spherical workpiece with an axle hole. The device comprises a discharge component, a taking component and a driving component, wherein the discharge component is provided with a discharge hole and is used for conveying the workpiece to the discharge hole; the taking component is used for sucking or clamping the workpiece; the driving component is used for driving the taking component to handle the workpiece on the taking component to a next station; the discharge component is connected with a height limiting baffle plate for keeping the axle hole of the workpiece facing towards the taking component. The automatic feeding device of the spherical workpiece with the axle hole can realize accurate conveying of the spherical workpiece with the hole and has high degree of automation, the conveying process is accurate and reliable, the conveying efficiency is high, the equipment cost is low, and popularization and use are facilitated.

Owner:SHENZHEN INST OF ADVANCED TECH

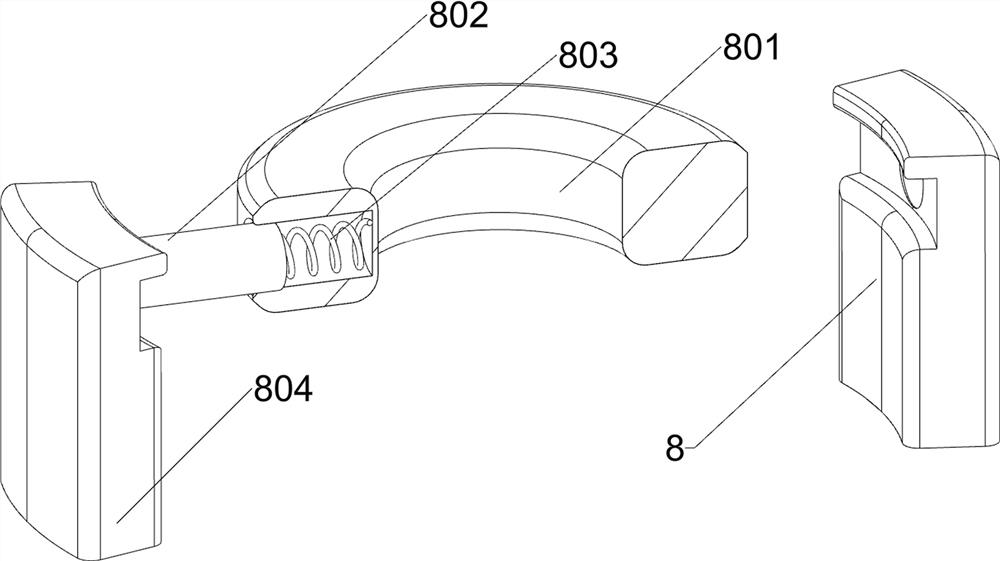

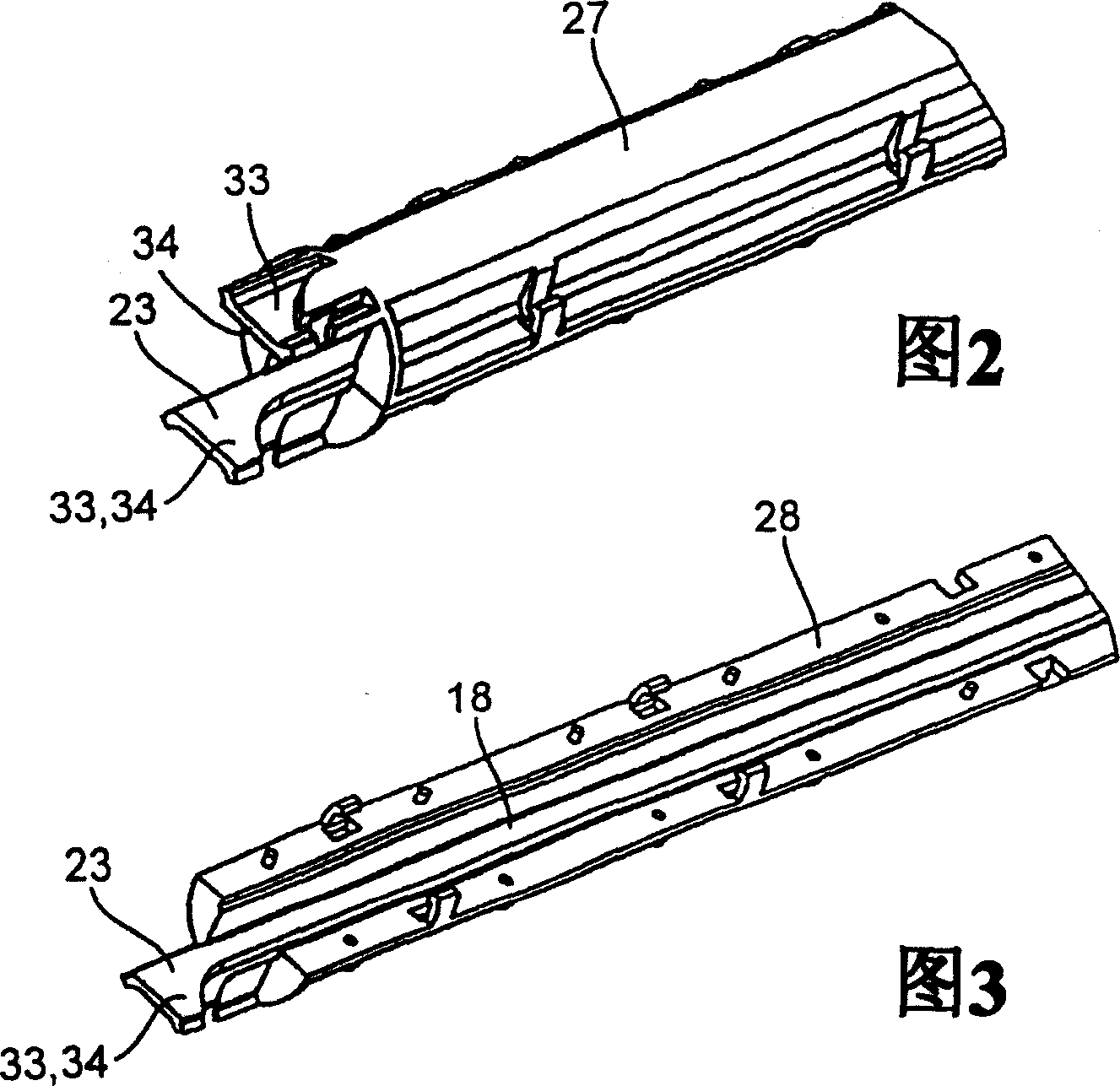

Hinge

ActiveCN105041843AReduce the number of gapsAvoid missingCasings/cabinets/drawers detailsPivotal connectionsMachiningElectronic equipment

The invention discloses a hinge. The hinge comprises a first rotary piece, a second rotary piece and a protective piece. The first rotary piece comprises a first connecting piece, a first rotary shaft and a first shaft sleeve. The second rotary piece comprises a second connecting piece, a second rotary shaft and a second shaft sleeve. The hinge is formed by splicing the first rotary piece, the second rotary piece and the protective piece. The protective piece of the proper length can be adopted for reducing the number of gaps between the first rotary piece, the second rotary piece and the protective piece, the gaps even can be prevented from being generated, and the technical effect that liquid matter in electronic equipment can be effectively prevented from leaking is achieved. Due to the fact that the hinge special for the electronic equipment can be composed of components which are lower in machining difficulty and simple in splicing manner, the technical effects that the production cost is effectively reduced and production and machining efficiency is improved are achieved.

Owner:LENOVO (BEIJING) CO LTD

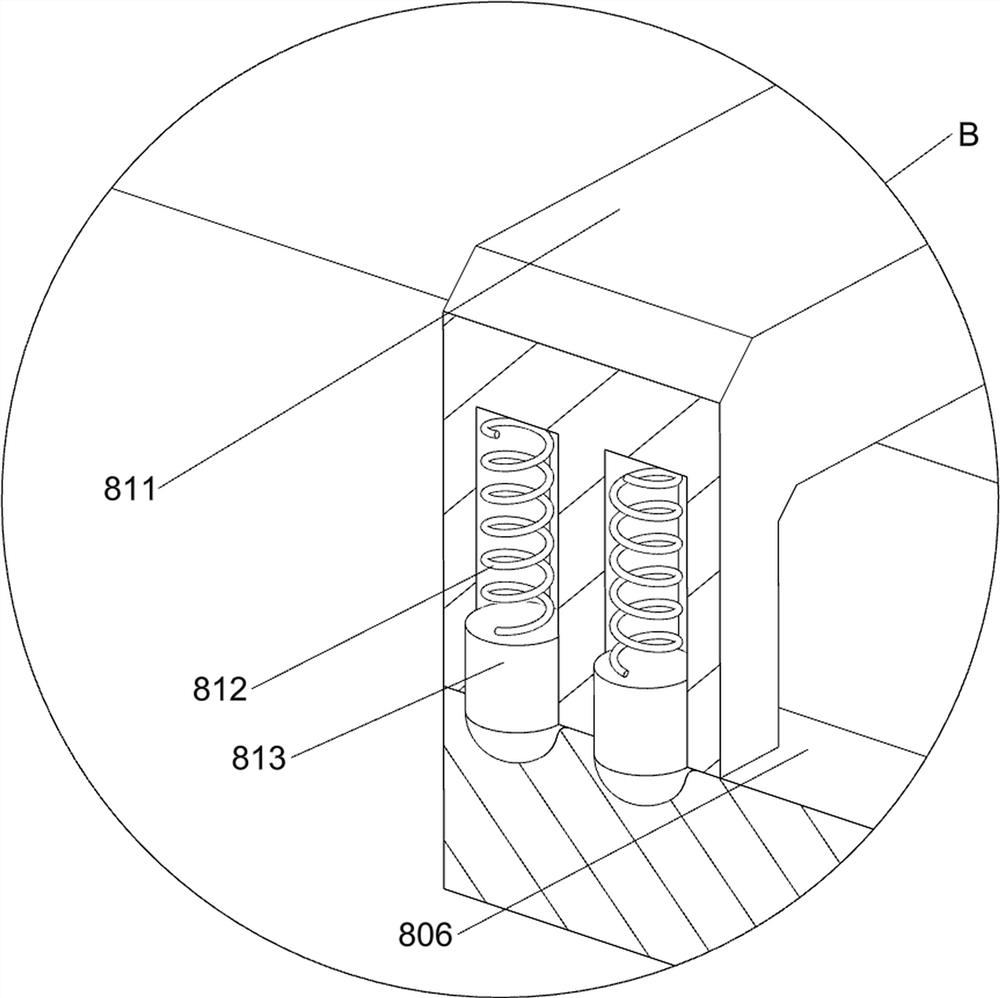

Cleaning device of biological culture dish for school teaching

InactiveCN112620275AImprove work efficiencyEasy to cleanDrying solid materials without heatHollow article cleaningPetri dishSprayer

The invention relates to cleaning equipment, in particular to a cleaning device of a biological culture dish for school teaching. The cleaning device of the biological culture dish for school teaching aims to achieve the technical effects of automatic cleaning, a good cleaning effect and convenient operation. According to the technical scheme, the cleaning device of the biological culture dish for school teaching comprises a base, a first supporting frame, a clamping assembly and a flushing assembly, wherein the first supporting frame is rotationally arranged in the middle of the lower side of the base, the clamping assembly is arranged on one side of the upper portion of the first supporting frame, and the flushing assembly is arranged on one side of the upper portion of the base. The cleaning device of the biological culture dish for school teaching has the beneficial effects that under the action of the flushing assembly, people press a second sliding rod downwards, a second spring is compressed, the second sliding rod can drive a third supporting frame and sprayers to move downwards, when the third supporting frame and the sprayers move to proper positions, people open the sprayers, the sprayers can clean a culture dish, and therefore the working efficiency of people is effectively improved.

Owner:周嫦娥

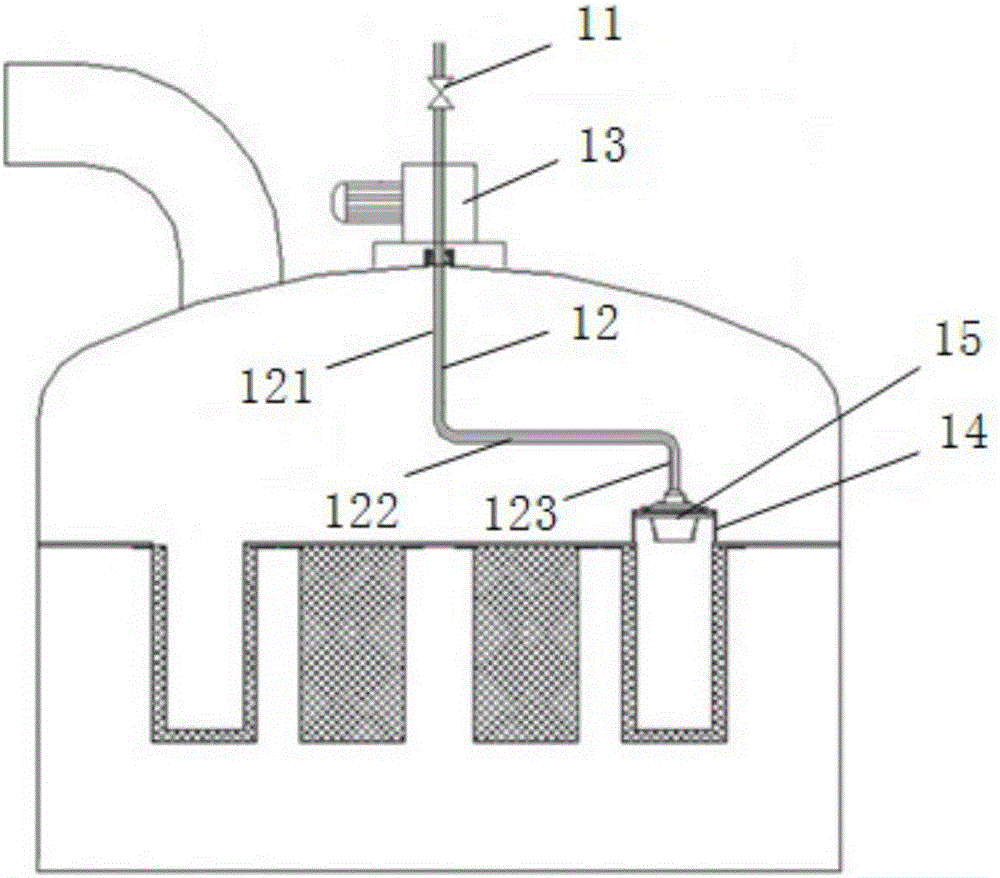

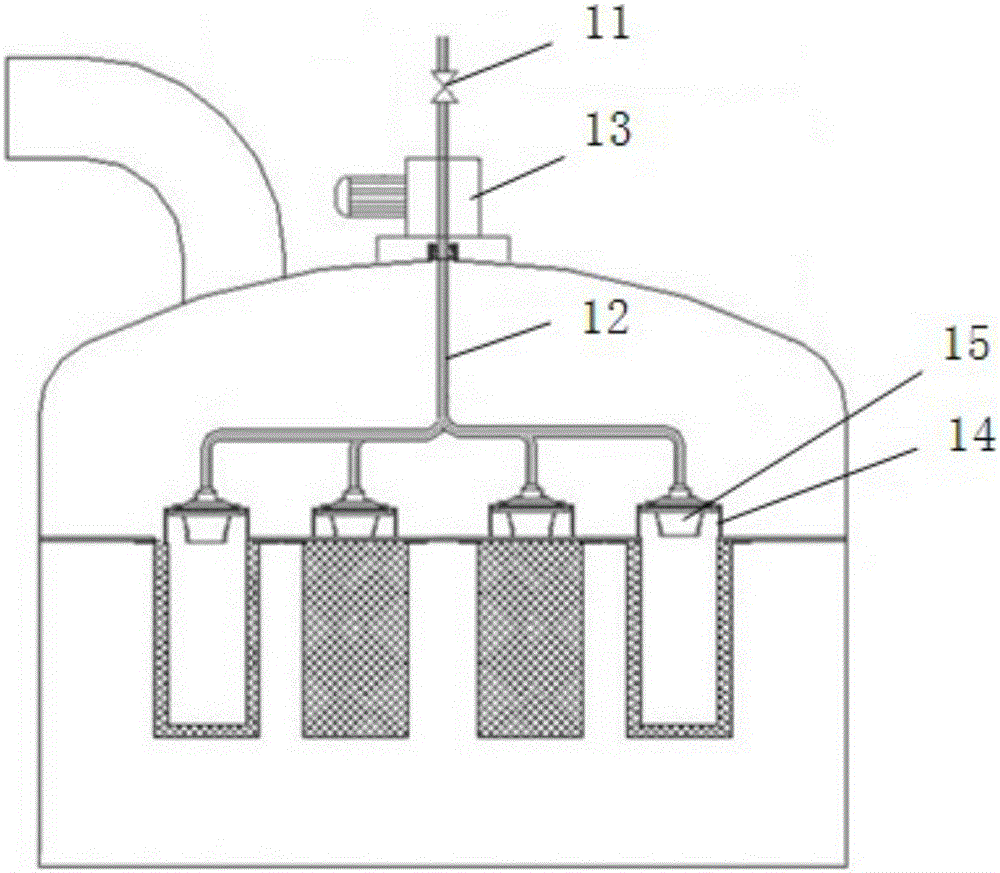

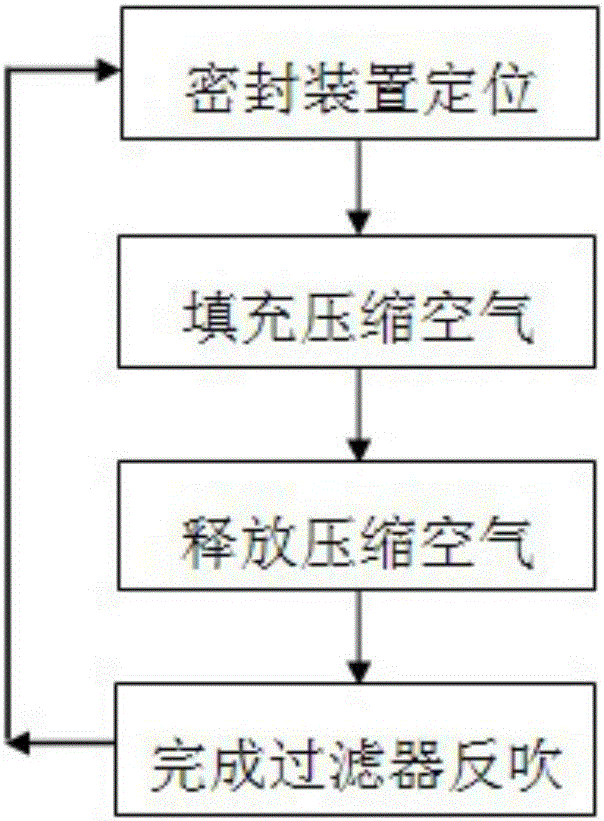

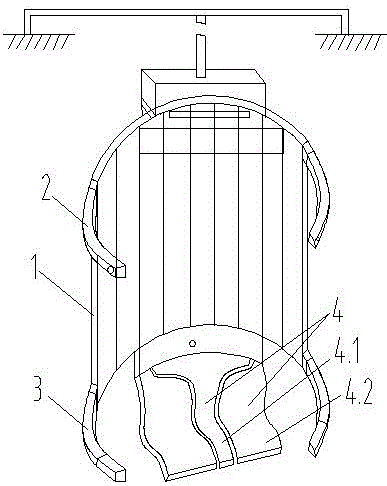

Back flushing device for fluidized granulator filter and back flushing method thereof

InactiveCN105903287AAchieve the effect of regenerationGuaranteed regeneration effectDispersed particle filtrationTransportation and packagingEngineeringControl valves

The invention provides a back flushing device for a fluidized granulator filter. The back flushing device comprises a compressed air control valve connected with a compressed air generating device, a compressed air pipeline, a rotating indexing motor and a sealing device, wherein the compressed air control valve is connected with a compressed air pipeline; the compressed air pipeline is controlled to rotate by the rotating indexing motor; the sealing device is driven to rotate by the compressed air pipeline; the sealing device is used for blocking the cavity of the filter. A back flushing method comprises the following steps of: (i) locating the sealing device; (ii) filling the compressed air; (iii) releasing the compressed air; and (iv) completing the back flushing of the filter. The rotating indexing motor of the back flushing device provided by the invention is used for driving the compressed air pipeline to rotate; the sealing device is driven to rotate by the compressed air pipeline; a plurality of sealing devices can be arranged, so that the purpose of simultaneously back flushing a plurality of filter cavities can be achieved; the discontinuous circulating back flushing process can be performed, so that the de-dusting effect is achieved.

Owner:TIANJIN YINUO PHARMA IND DESIGN CO LTD

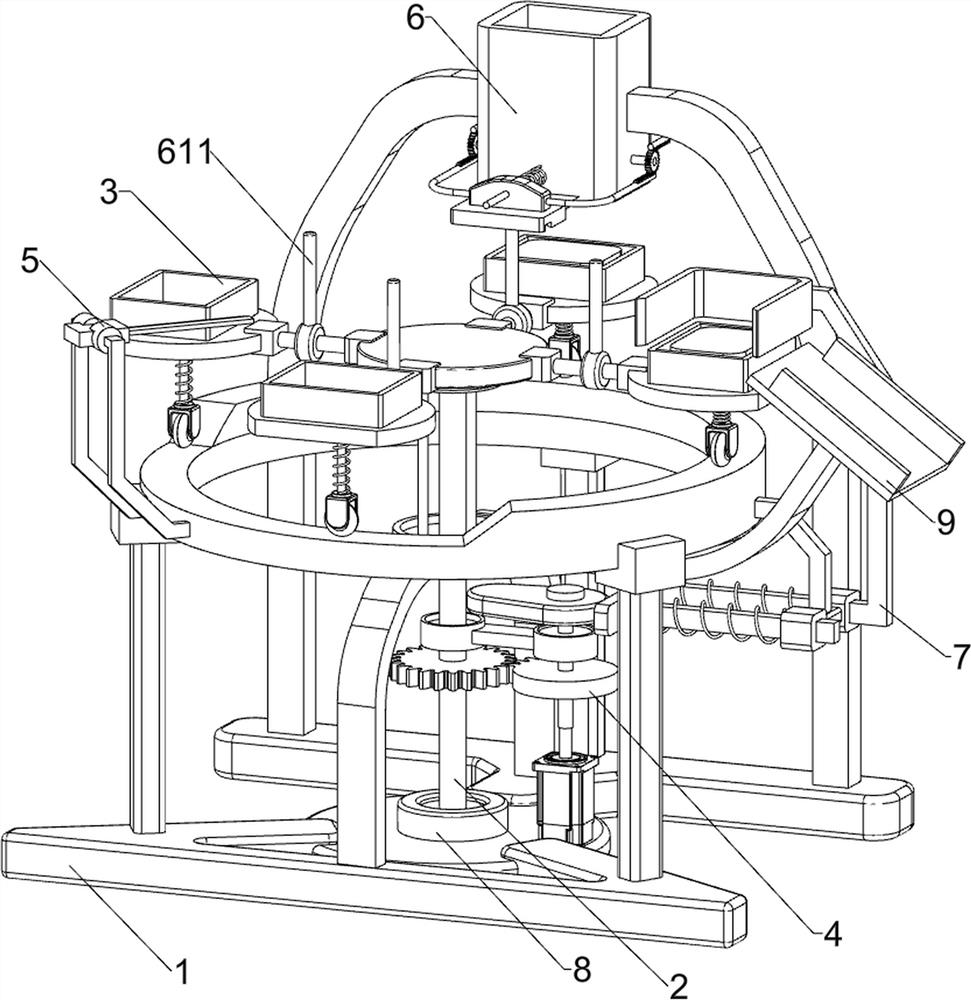

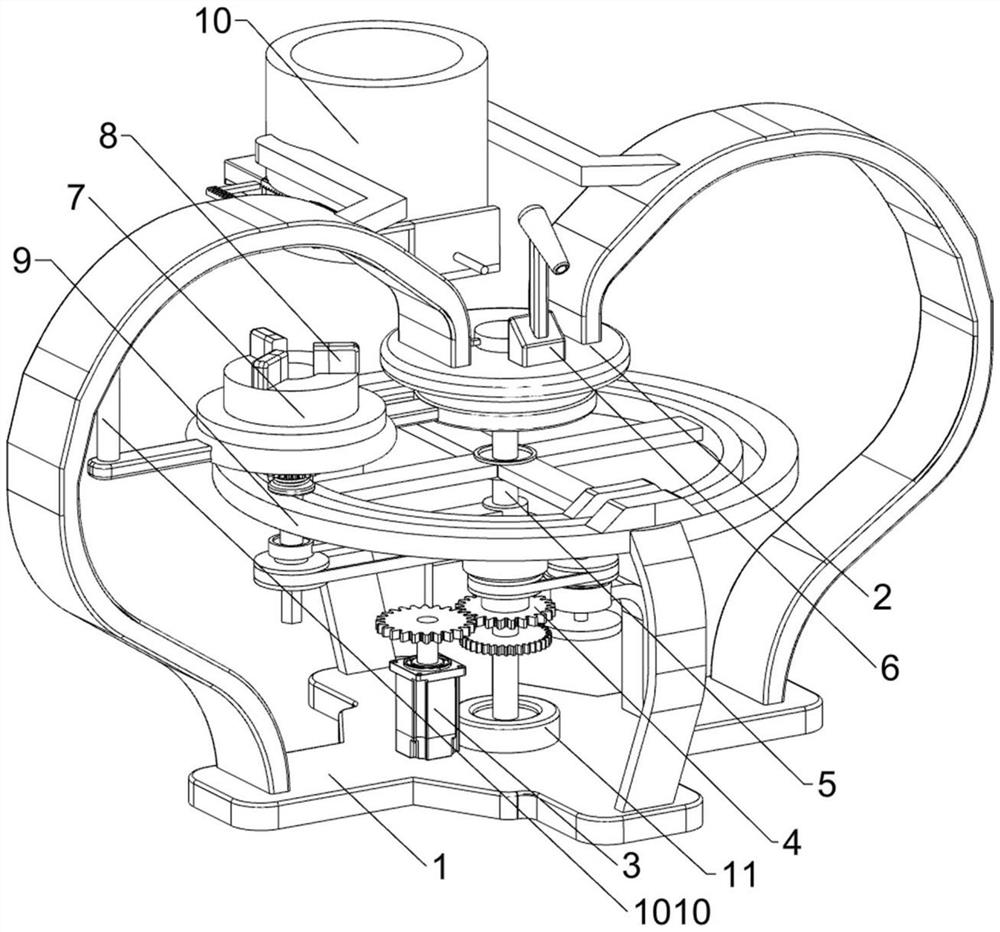

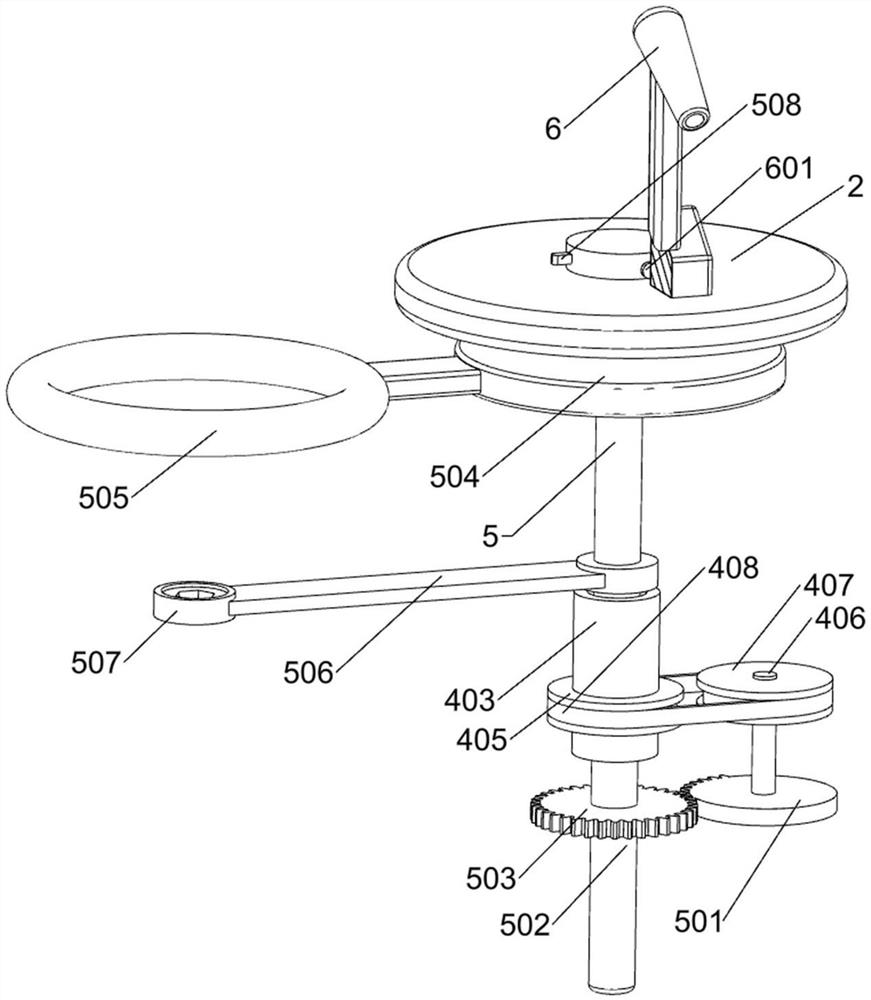

Polyurethane material shaping and cutting device for new energy automobile

ActiveCN112692899AEasy to operatePrecise rotational positionMetal working apparatusNew energyDrive shaft

The invention relates to a cutting device, and especially relates to a polyurethane material shaping and cutting device for a new energy automobile. The technical problem to be solved is to provide the polyurethane material shaping and cutting device for the new energy automobile, capable of realizing automatic cutting and automatic feeding, and convenient to operate. The technical scheme is as follows: the polyurethane material shaping and cutting device for the new energy automobile comprises a base, a first supporting frame, a charging assembly and a transmission assembly, wherein the first supporting frame is rotationally arranged at the middle part of the base; the charging assembly is arranged between the first supporting frame and the base; and the transmission assembly is arranged a one side of the middle part of the base. When people start a motor, an output shaft of the motor drives a transmission shaft to rotate, when a first gear rotates, the first supporting frame is driven to rotate, the first supporting frame drives a first connecting rod, a first baffle and a top plate to rotate around the first supporting frame, and meanwhile, the top plate drives a rolling wheel to move on a contact frame; and when a polyurethane material makes contact with a belt type cutter, the belt type cutter cuts the polyurethane material.

Owner:JIANGXI COLLEGE OF APPLIED TECH

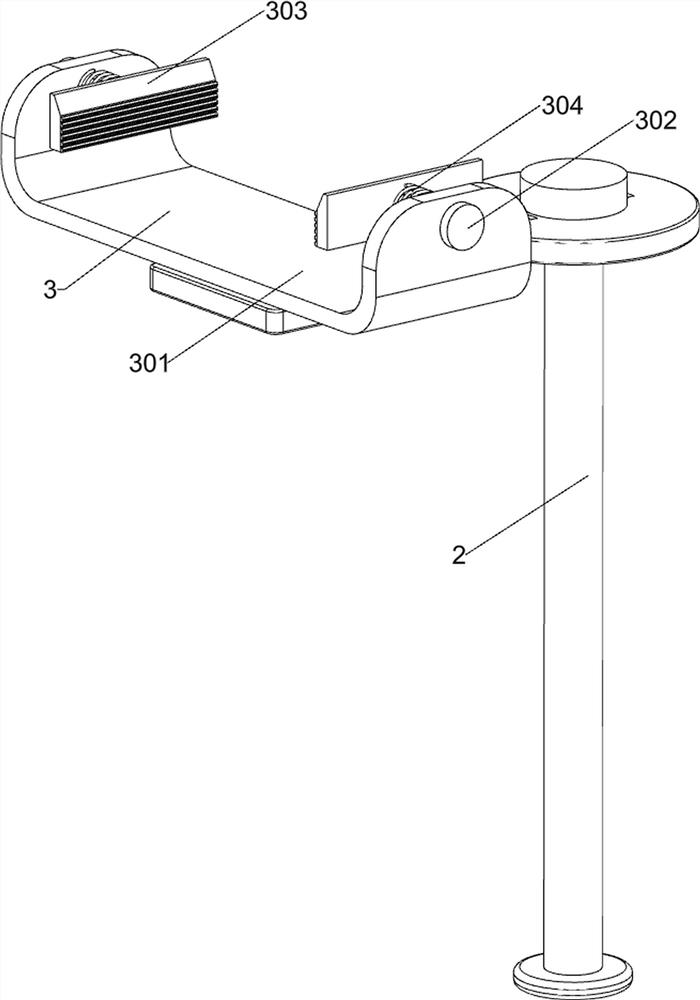

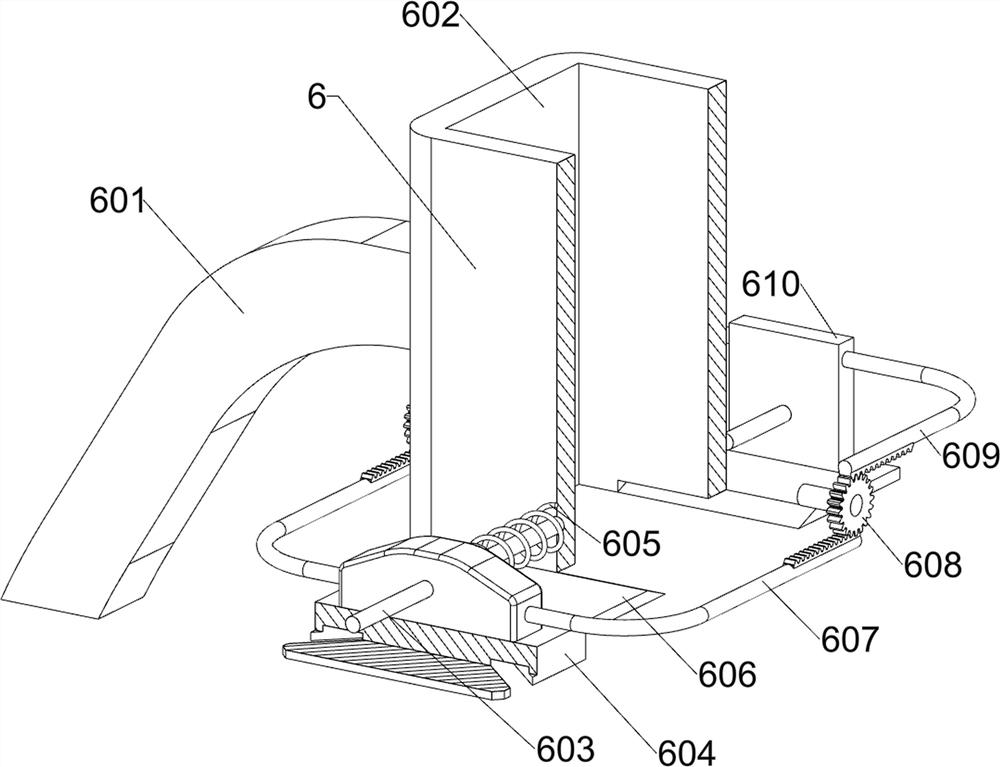

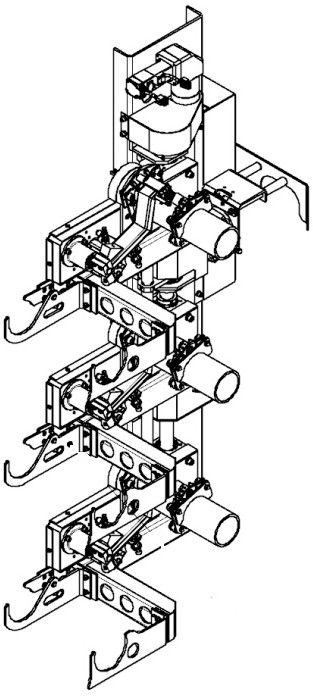

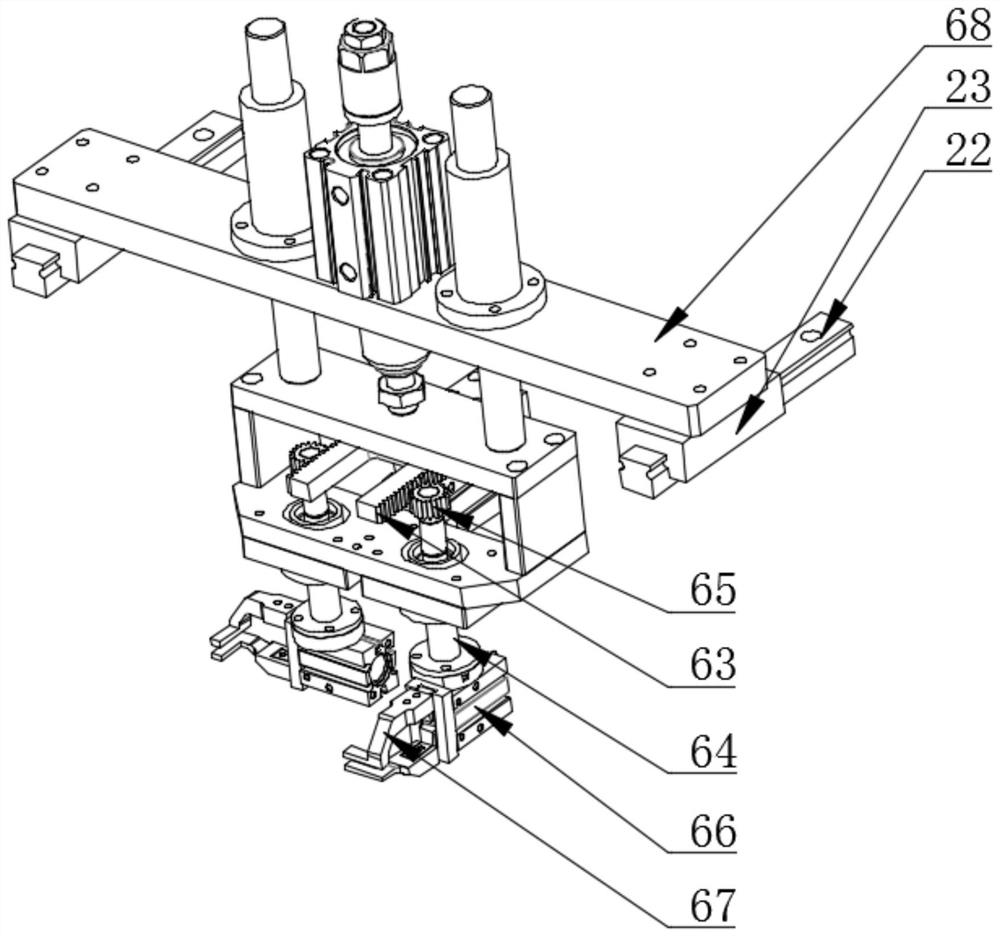

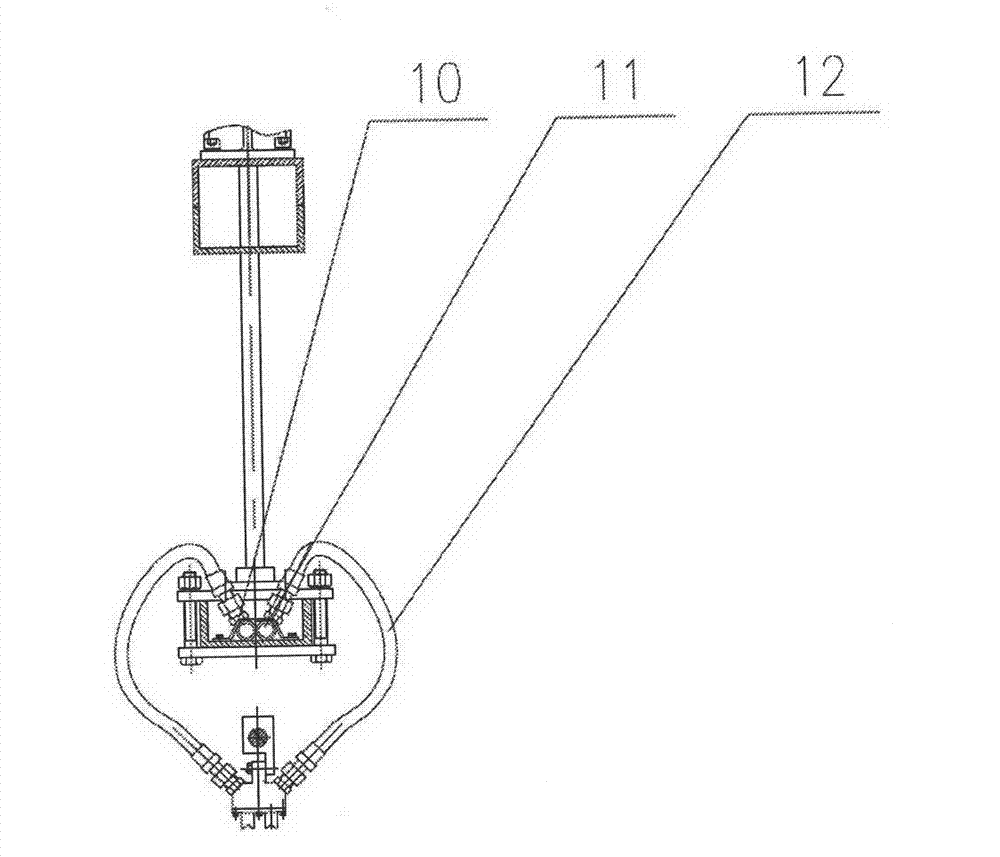

Loading and unloading manipulator of automatic doffing robot of elasticizer

The invention discloses a loading and unloading manipulator of an automatic doffing robot of an elasticizer. The loading and unloading manipulator comprises a back plate, a paper tube taking and placing device, an electrical box, a rotating device, a swing rod mechanism, a yarn ball taking and placing device and a swing limiting mechanism, wherein the paper tube taking and placing device and the yarn ball taking and placing device are fixed on the swing rod mechanism through connecting plates; the swing rod mechanism is fixed on the back plate through mounting seats at two ends; a rotating shaft of the swing rod mechanism penetrates through the rotating device and the swing limiting mechanism; the swing rod mechanism is mounted on the back plate through the mounting seats; a swing shaft ofthe swing rod mechanism is connected with a swing plate of the rotating device; and a sensing plate of the swing limiting mechanism is fixed on the rotating shaft. The loading and unloading manipulator is compact in structure and reasonable in layout; the rotating shaft of the swing rod mechanism can drive the paper tube taking and placing device and the yarn ball taking and placing device to swing simultaneously, and the rotating device can drive the swing shaft of the swing rod mechanism to swing independently, so that action switching among a yarn ball taking posture, a paper tube loadingposture and a yarn ball placing and paper tube taking posture is realized.

Owner:苏州澳钍智能科技有限公司

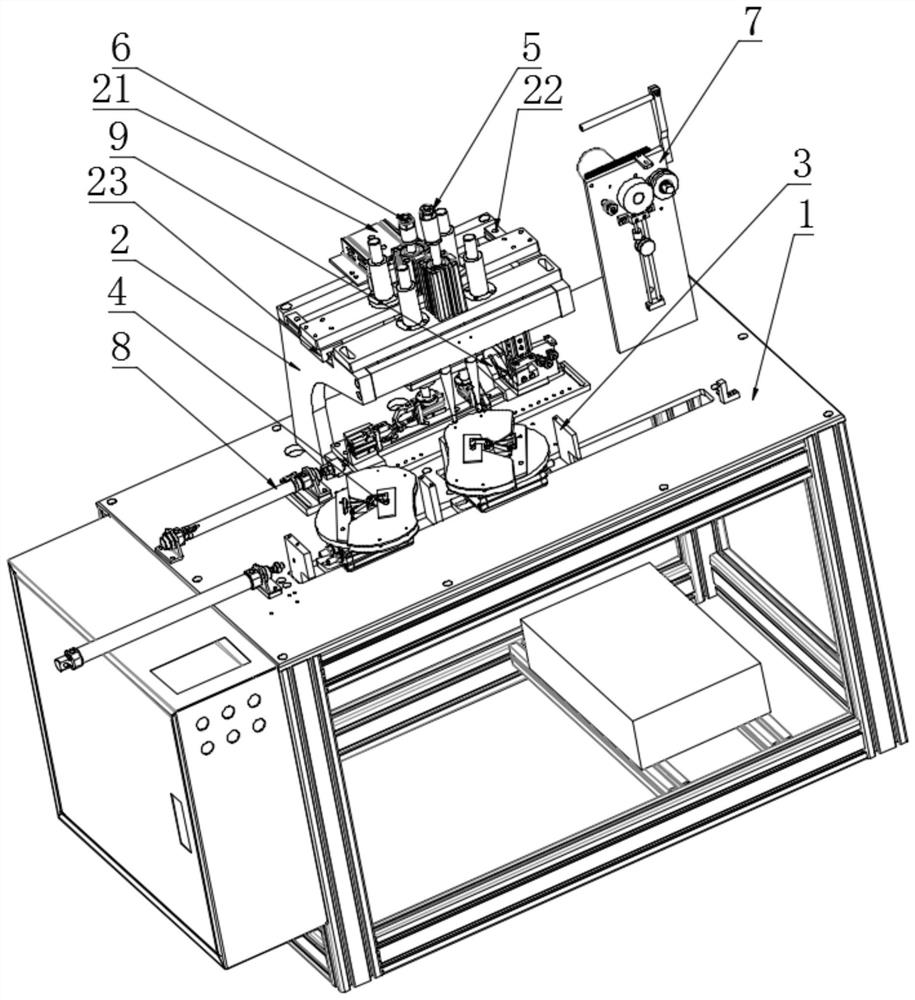

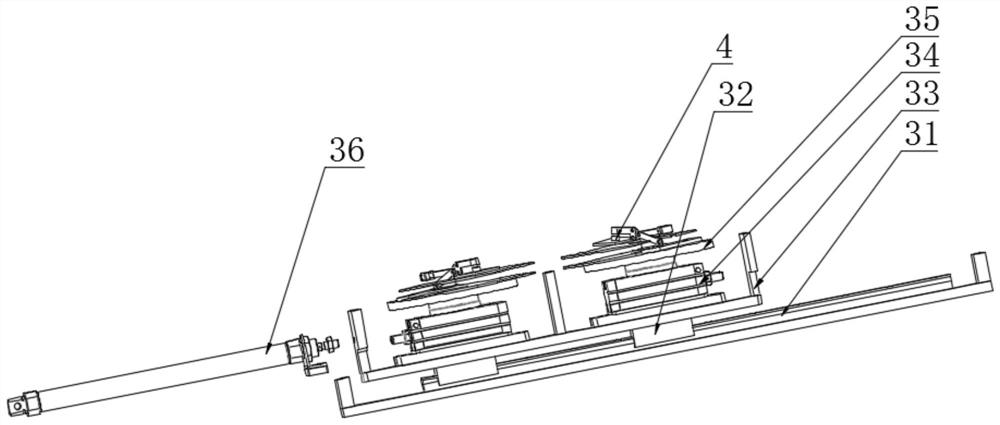

N95 mask double-station strap spot welding machine

PendingCN111907067AReduce equipment costsReduce labor costsDomestic articlesProtective garmentEngineeringSpot welding

The invention relates to an N95 mask double-station strap spot welding machine, and belongs to the field of N95 mask strap spot welding machines. The device comprises a workbench, a support and a positioning device which are fixedly connected are arranged on the workbench; a welding device and a movable strap clamping device are arranged on the support, and a strap pulling device connected with the workbench is arranged below the strap clamping device; and the positioning device comprises a first sliding guide rail fixed to the workbench, a first sliding block which is slidably connected is arranged on the first sliding guide rail, a supporting frame is arranged on the first sliding block, two rotating air cylinders which are parallel are arranged on the supporting frame, and positioning tools which are fixedly connected are arranged on the rotating air cylinders. Compared with the prior art, the machine has the beneficial effects that firstly, two welding stations are arranged on onepositioning device, that is, two welding stations are arranged on one strap welding machine, and only one person is needed for one welding station, so that the equipment cost and the labor cost of anenterprise are reduced, and the efficiency is improved.

Owner:烟台思壮智能科技有限公司

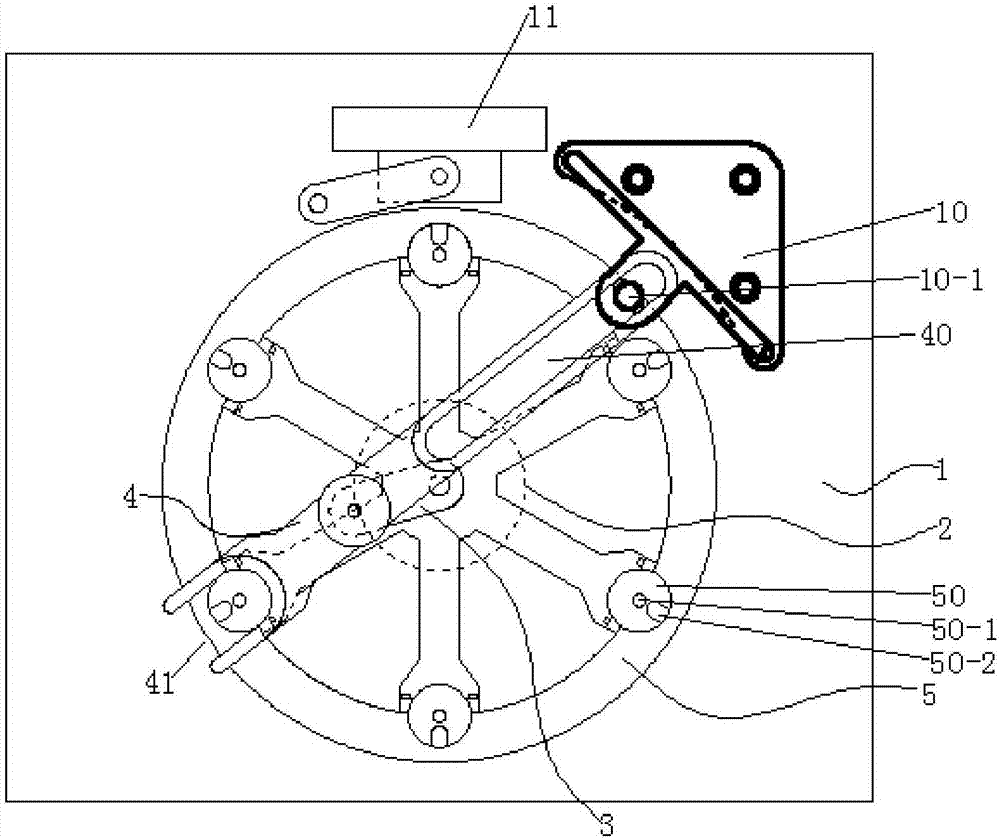

Stepping tapping device for ear tag injection molded part

ActiveCN107999897AImprove coherenceStepping wire implementationPrecision positioning equipmentThread cutting feeding devicesEar tagEngineering

The invention discloses a stepping tapping device for an ear tag injection molded part. The stepping tapping device comprises a base plate, a motor, a rocker, a driving rod and a turntable frame; a limiting guide support is arranged at the corner of the base plate; a guide column is arranged on the limiting guide support; a pneumatic tapping machine is arranged in the middle of the edge of the base plate; the motor is connected to the lower end of the base plate through bolts; one end of the rocker is connected to an output shaft of the motor, and the other end of the rocker is hinged to the lower part of the drive rod; a long groove is formed in the driving rod and can slide under the limit of the guide column; and the turntable frame is connected to the base plate in a rotating mode. Thestepping tapping device has the advantages that the stepping tapping operation can be carried out after a male ear tag body is subjected to injection molding, the tapping efficiency is high, the thread consistency is good, and the adjustment of changing the thickness of a tag pole of the male ear tag body can be facilitated.

Owner:HEBEI BOCHEN HUSBANDRY TECH CO LTD

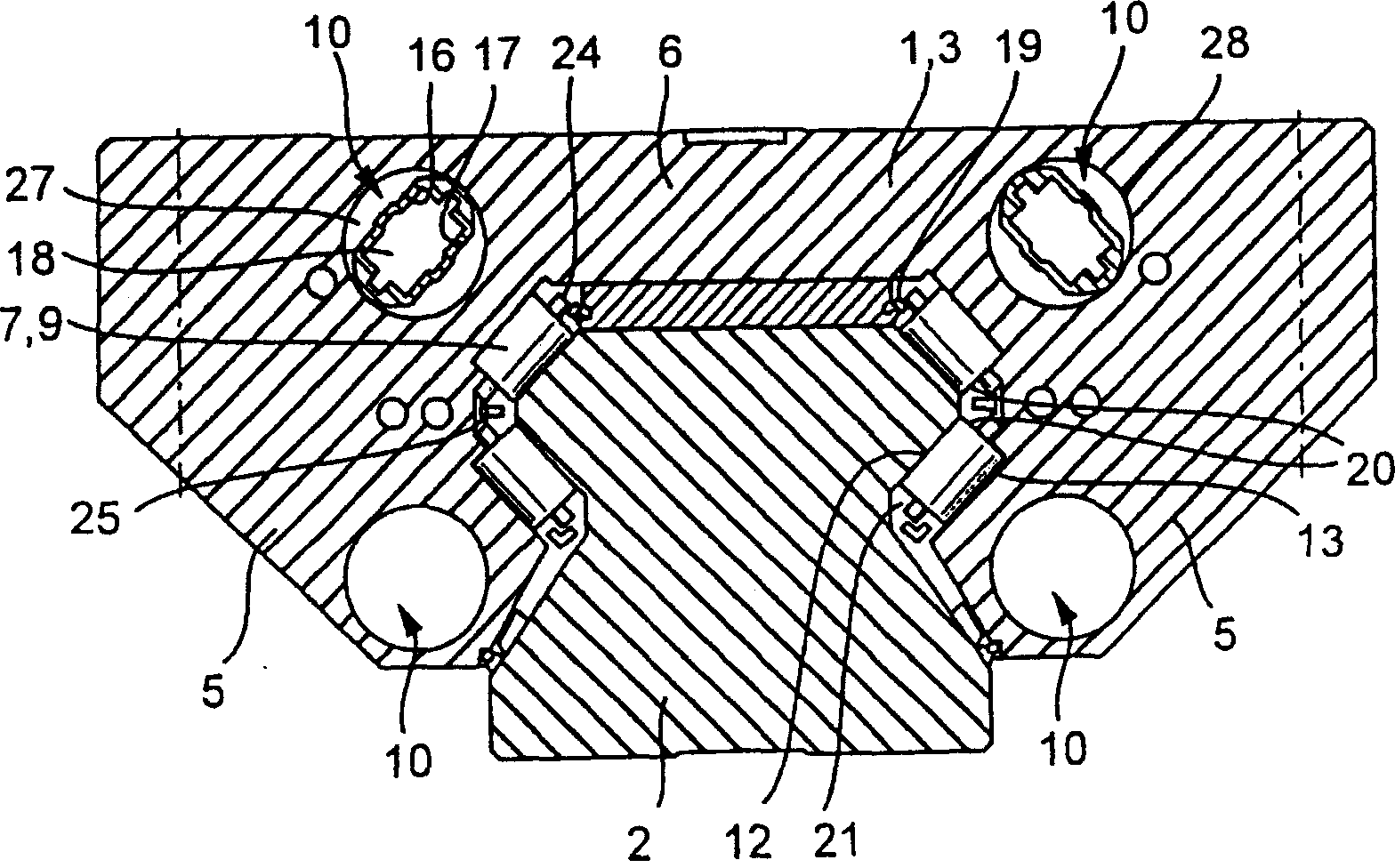

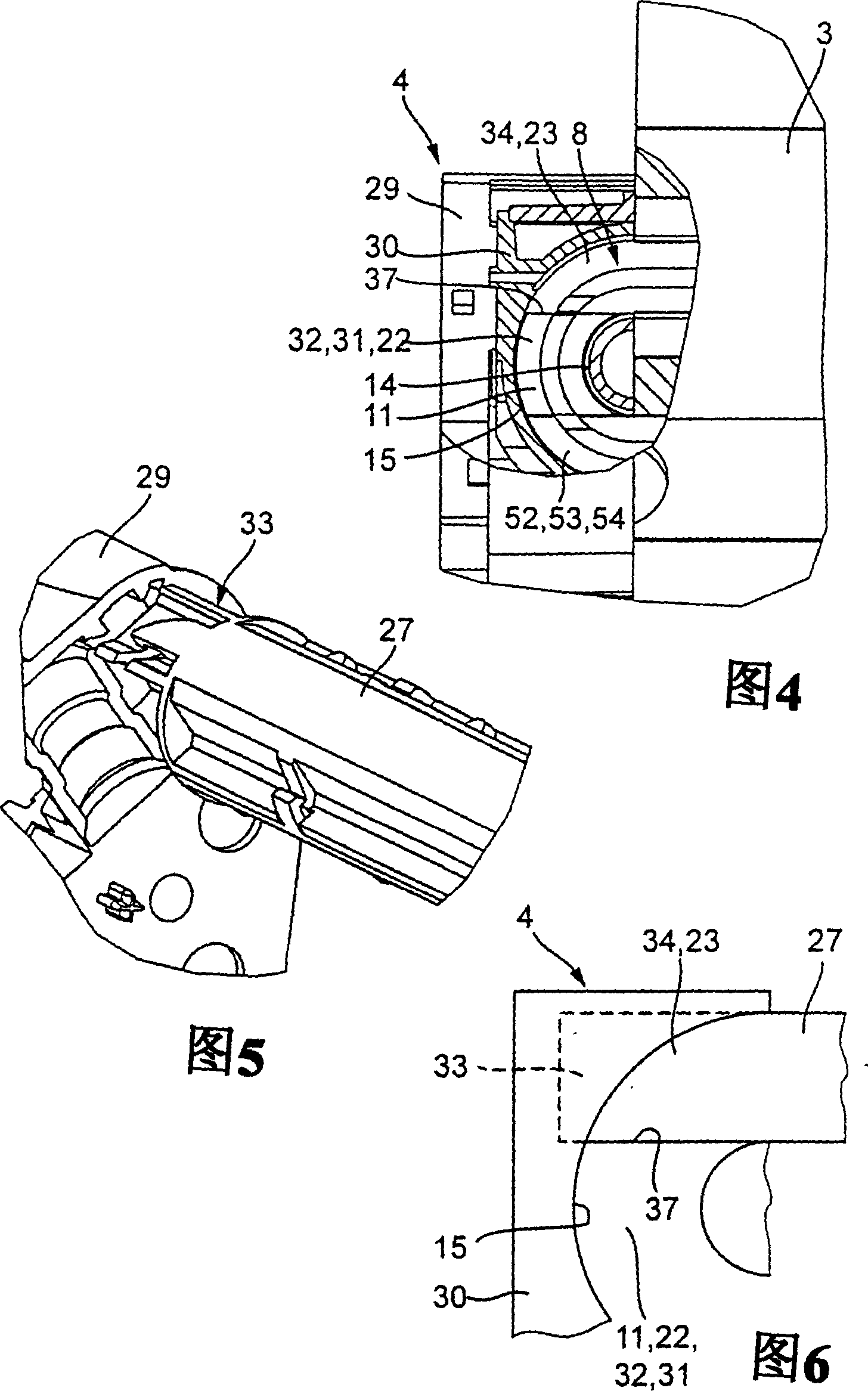

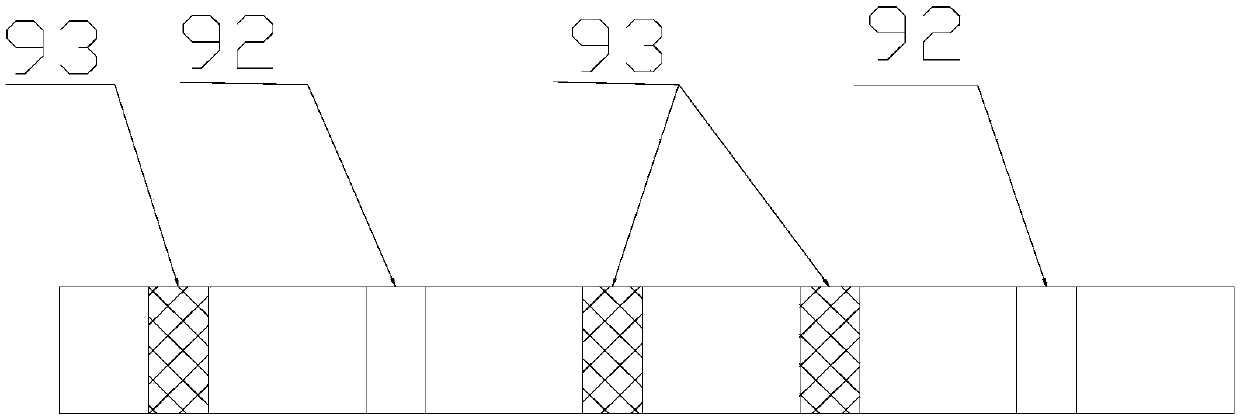

Linear roller bearing

InactiveCN1662750ASize has no effectPrecise rotational positionLinear bearingsRolling-element bearingEngineering

The invention relates to a linear roller bearing comprising a guiding carriage (1) which can be mounted on a guiding rail (2) by means of rolls (7) and comprises at least one continuous roll channel (8) for the rolls (7). Said roll channel (8) comprises a carrier channel (9) for carrying rolls (7), a return channel (10) for returning rolls (7), and two deviation channels (11) which interconnect the carrier channel (9) and the return channel (10). The guiding carriage (1) comprises a carrier body (3) containing the return channel (10) and the carrier channel (9), and end parts (4) which contain the deviation channels (11) and are arranged on both front sides of the carrier body (3). The return channel (7) comprises a return pipe (11), the ends of said pipe being connected to the end parts (10). The roll channel comprises tracks for the rolls and lateral surfaces for laterally defining the roll channel. The return pipe (11) is provided with tongues (33) which engage in the end part (4), the facing tongue surfaces (34) forming the lateral surfaces (22) of the deviation channel (11). A separation joint (37) is arranged between each tongue (33) and the end limb (4) at least parallel to the return pipe (11).

Owner:SCHAEFFLER TECH AG & CO KG

Underground rescue robot

InactiveCN105904464AReduce shakingIncrease chances of survivalBreathing protectionManipulatorRescue robotSurvival probability

The invention discloses an underground rescue robot. The underground rescue robot comprises a main body, upper arms and lower arms. The upper arms are horizontally mounted on the two sides of the upper portion of the main body. The lower arms are horizontally mounted on the two sides of the lower portion of the main body. Supporting arms are rotatably mounted at the bottom of the main body. A lifting device is mounted at the top of the main body. An energy storage device is mounted on a body of the main body. The energy storage device is connected with the main body, the upper arms, the lifting device, the lower arms and the supporting arms. By adopting the underground rescue robot provided by the invention, a child falling into a well can be rescued quickly; well digging is avoided, the rescue efficiency is higher, the rescue time is shortened, and accordingly the survival probability of the child falling into the well is increased.

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

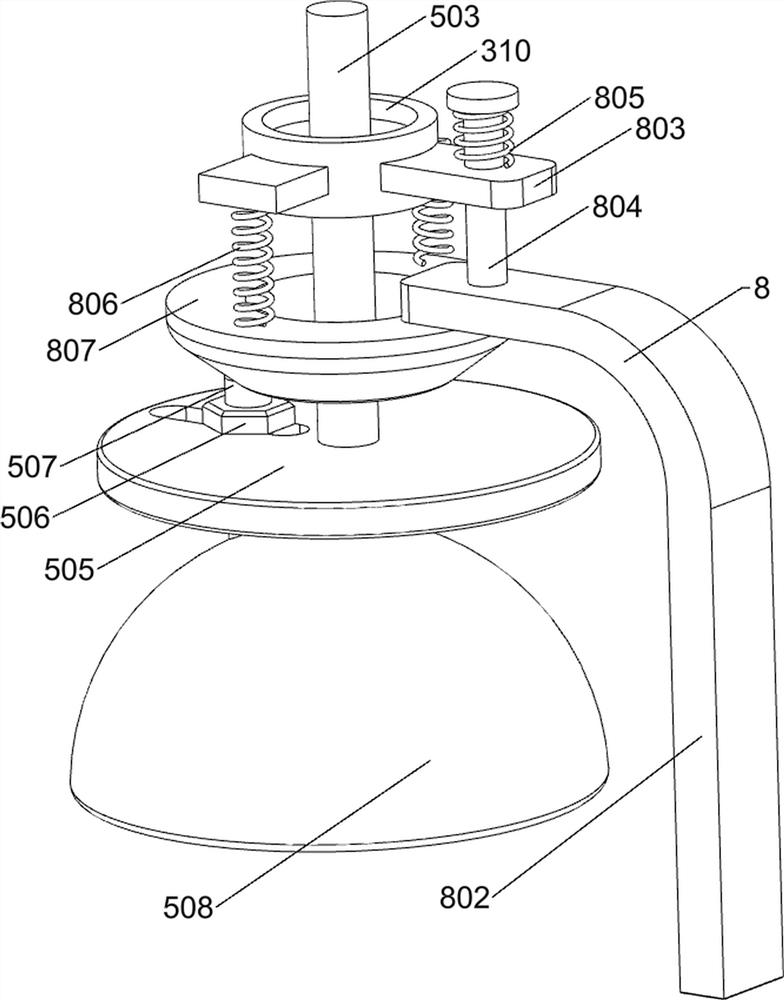

High-reflectivity powder coating spraying equipment for lamp production

ActiveCN112808545AImprove work efficiencyEasy to unloadLiquid surface applicatorsCoatingsHigh reflectivityTouch switch

The invention relates to spraying equipment, in particular to high-reflectivity powder coating spraying equipment for lamp production. The high-reflectivity powder coating spraying equipment for lamp production aims at achieving the technical effects that automatic lamp spraying is achieved, the spraying effect is good, and the operation is easy. According to the technical scheme, the high-reflectivity powder coating spraying equipment for lamp production comprises a base; a first supporting plate arranged on the upper middle portion of the base; a motor arranged on one side of the upper middle portion of the base; and a transmission assembly arranged on one side of the upper middle portion of the base. The high-reflectivity powder coating spraying equipment has the beneficial effects that under the action of an intermittent rotating assembly, people place a lamp on a storage rack, a motor is started, through a series of transmission, a third transmission rod can drive a first contact rod to rotate by 90 degrees, the first contact rod makes contact with a touch switch, a spray head can spray paint to the lamp, and the working efficiency of people is effectively improved.

Owner:济南汇金电器有限公司

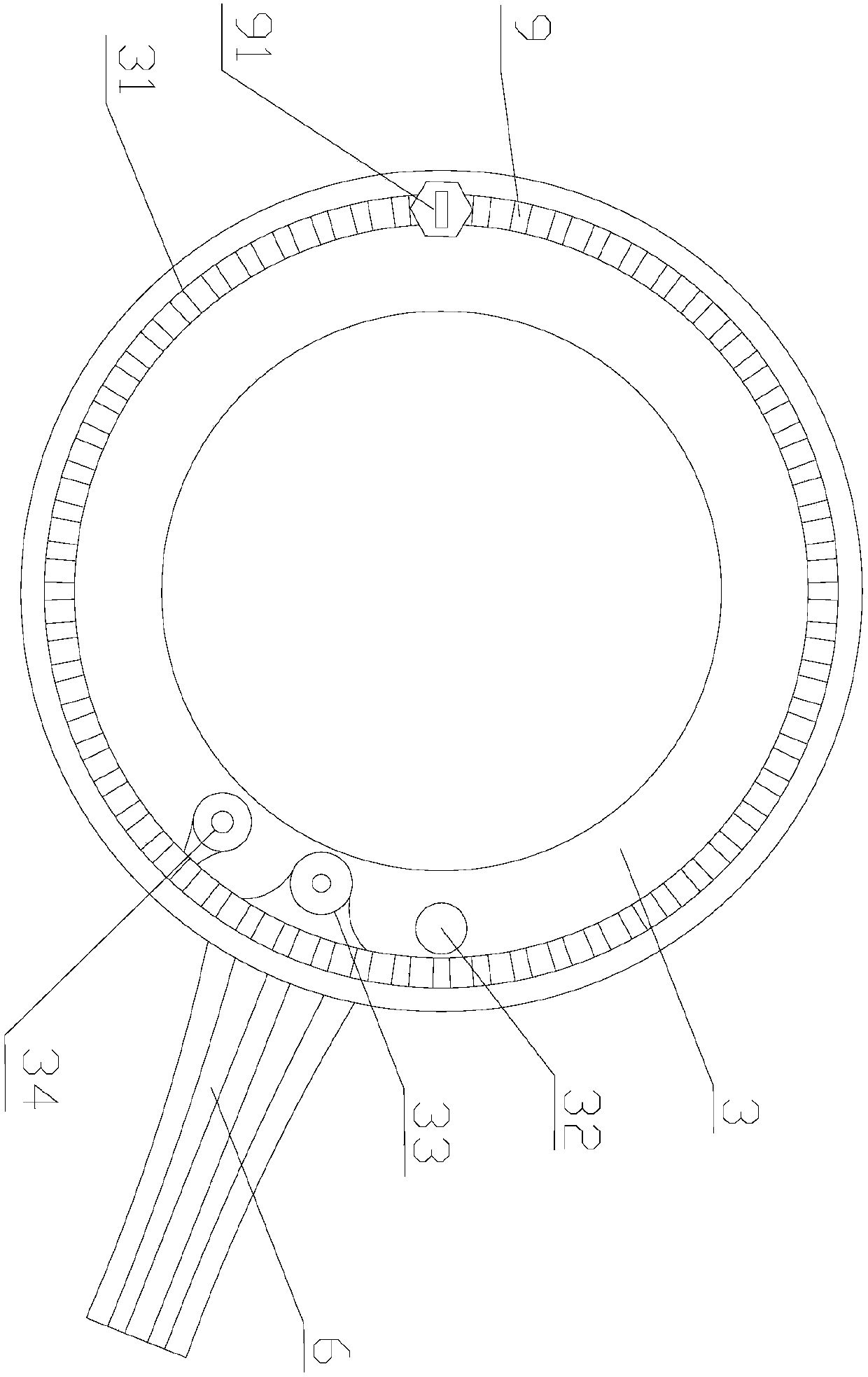

Angular displacement coding sensor

The invention relates to the field of electronic components, and more particularly to an angular displacement coding sensor, which comprises a base and a sealing cover, wherein the space formed by thebase and the sealing cover is internally provided with an annular rotating brush supporting plate and an annular fixing piece; the side, close to the rotating brush supporting plate, of the fixing piece is provided with an annular coder track with an opening; a joint at one end of the opening of the coder track is connected with a wire group and is slidably contacted with a first brush; the firstbrush is connected with a first brush holder fixed on one side of the rotating brush supporting plate; the rotating brush supporting plate is slidably contacted with a second brush; the fixing plateis provided with a second brush holder supporting the second brush; the coder track is uniformly provided with a plurality of coder scales; the first brush is provided with a sensing element corresponding to the coder scale; and the sensing element reads the coder scale to convert the reading to a coder output signal. The effective electric stroke range of the angular displacement sensor is large,a full circumference of 360 DEG can be achieved, the linear precision is high, and stable pulse coding signals can be outputted.

Owner:WENZHOU OCLOUD TECH CO LTD

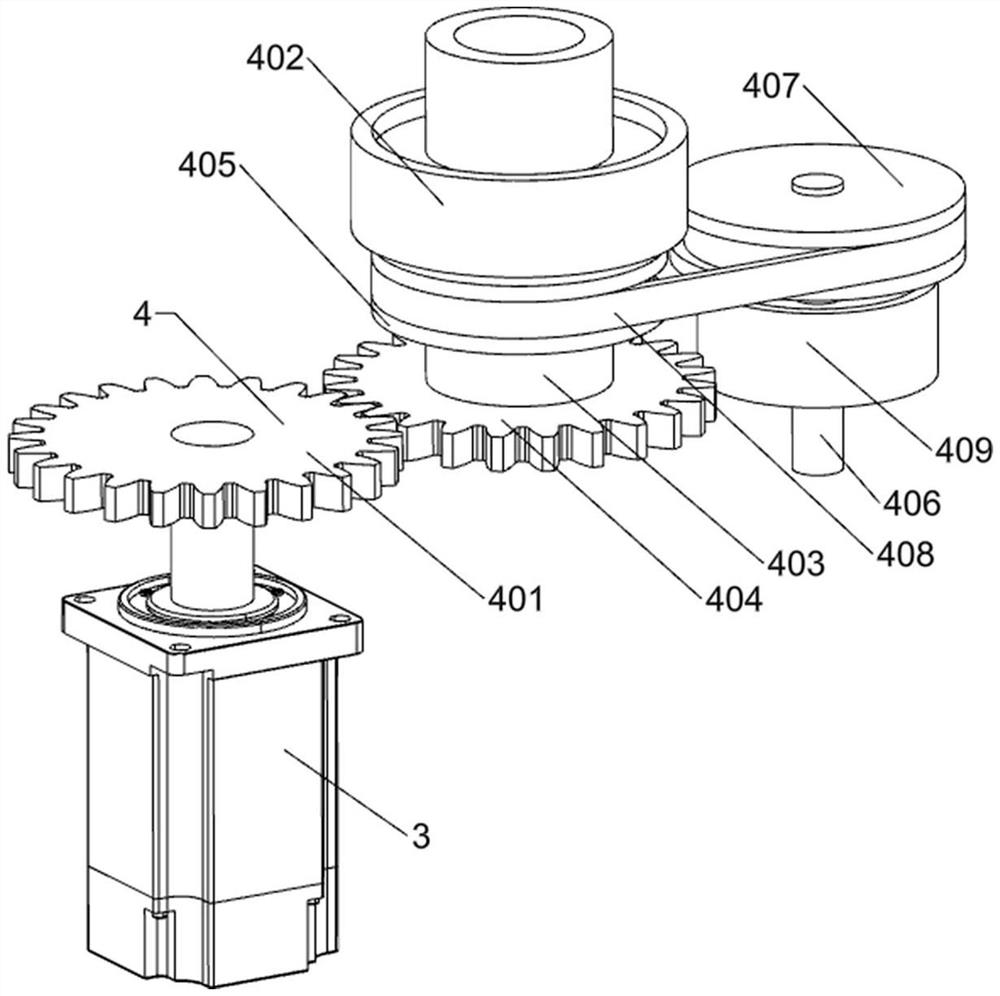

Automatic tripod pin machining device based on intelligent manufacturing

PendingCN114770092AReduce cumbersomeSimple stepsAssembly machinesMetal working apparatusMachiningWorkbench

The invention relates to the technical field of tripod machining, in particular to an intelligent manufacturing-based tripod automatic machining device which comprises a workbench, a feeding assembly and three material moving mechanisms, and the three material moving mechanisms are arranged on the workbench in a surrounding mode with the axis of the workbench as the axis. A rotating assembly used for driving all the material moving mechanisms to rotate is arranged below the workbench, a feeding frame matched with the three material moving mechanisms is arranged on the feeding assembly, each material moving mechanism comprises a material pushing assembly, a lifting assembly and a fixing assembly, the material pushing assembly is located on the workbench, a sliding table is arranged on the material pushing assembly, and the lifting assembly is located on the sliding table; the lifting assembly is provided with a lifting frame, the fixing assembly is located on the lifting frame, the fixing assembly is provided with an expansion shaft and a push plate, the three material moving mechanisms are arranged, meanwhile, the three shafts of the three-pin frame are sleeved with rollers, the tedious and optimized steps of sequentially sleeving the three-pin frame with the rollers are reduced, and the working efficiency is improved.

Owner:魏帅起

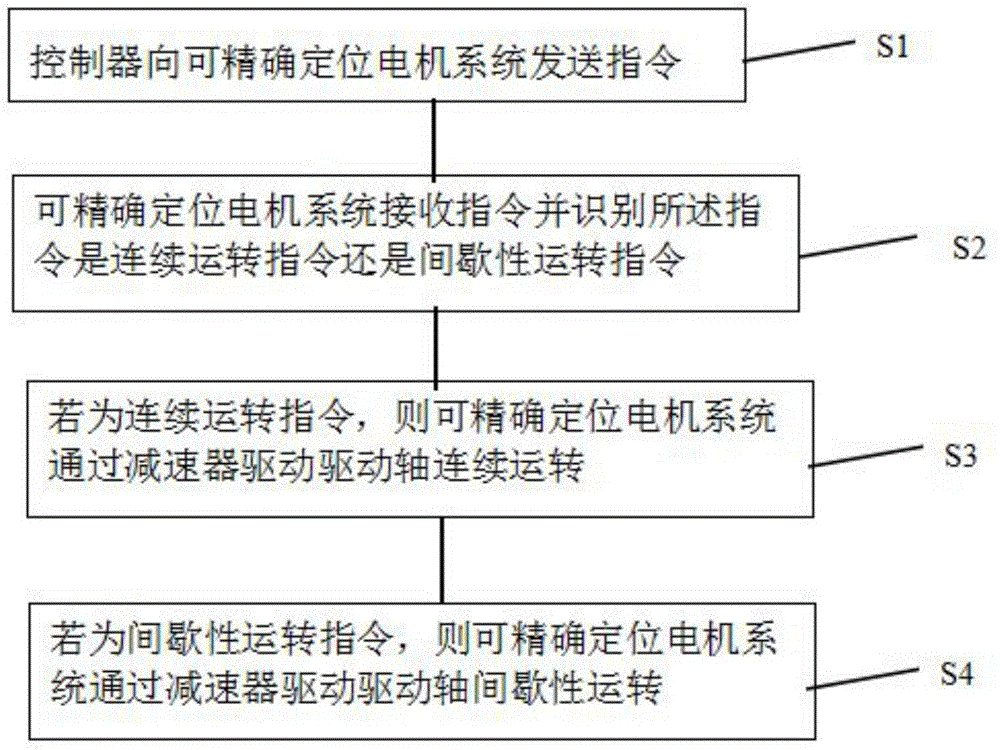

Drive method for mechanical drive device and mechanical drive device

The invention provides a drive method for a mechanical drive device and the mechanical drive device. The drive method comprises the following steps that a controller sends a command to a motor system capable of realizing accurate positioning; the motor system capable of realizing accurate positioning receives the command and identifies whether the command is a continuous running command or an intermittent running command; if the command is the continuous running command, the motor system capable of realizing accurate positioning drives a drive shaft to continuously run through a reducer; and if the command is the intermittent running command, the motor system capable of realizing accurate positioning drives the drive shaft to intermittently run through the reducer. With adoption of the drive method for the mechanical drive device and the mechanical drive device, the features of intermittent rotation and continuous rotation of a mechanical device can be shared by same equipment, thus intermittent rotation and continuous rotation coexist on one device, and electromechanical integration control is applied to mechanical equipment.

Owner:欧体自动化技术(上海)有限公司

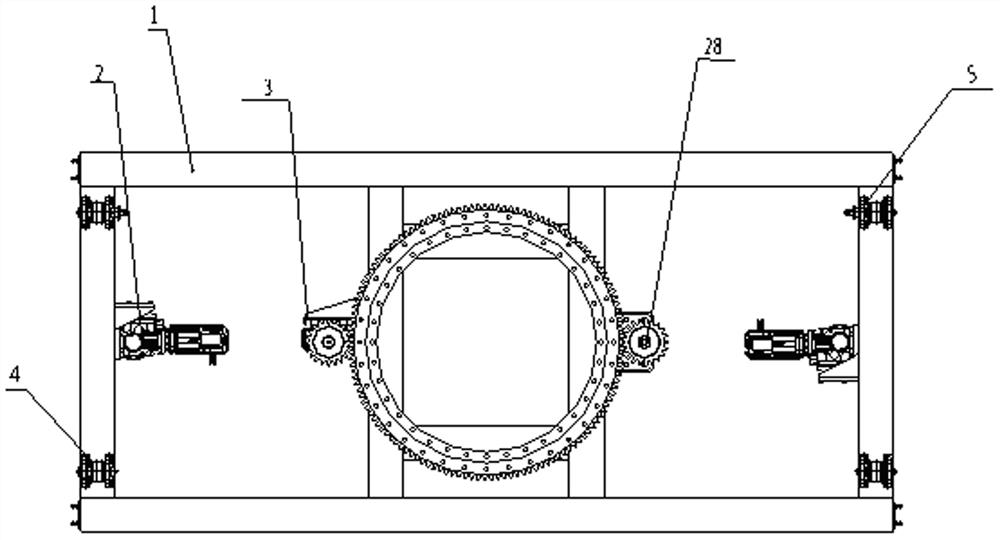

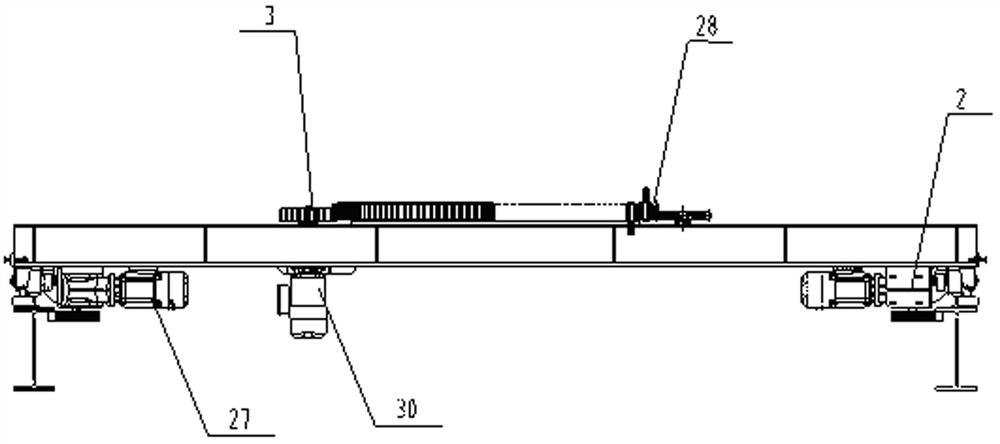

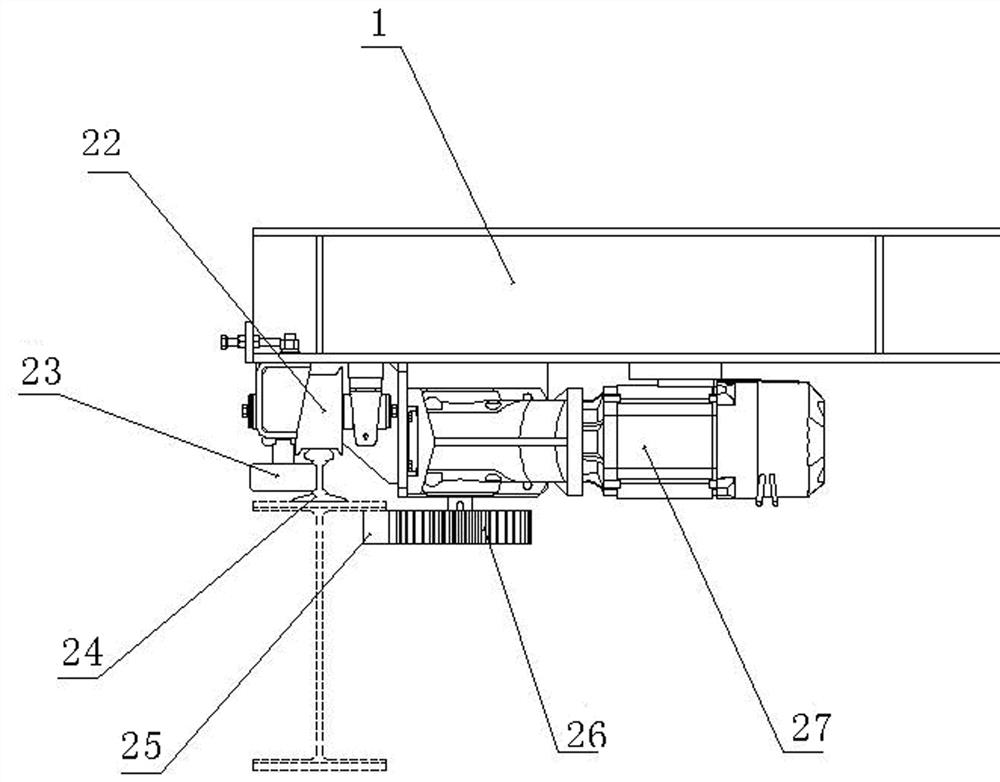

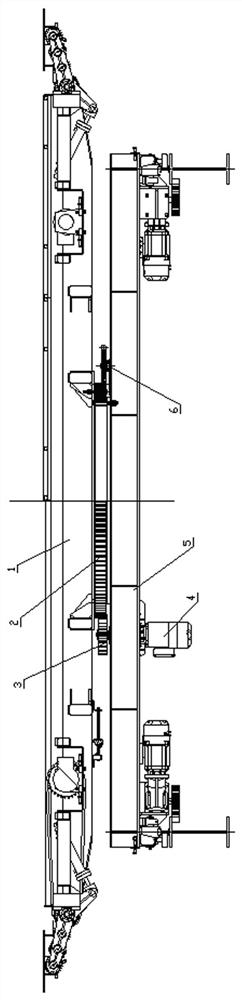

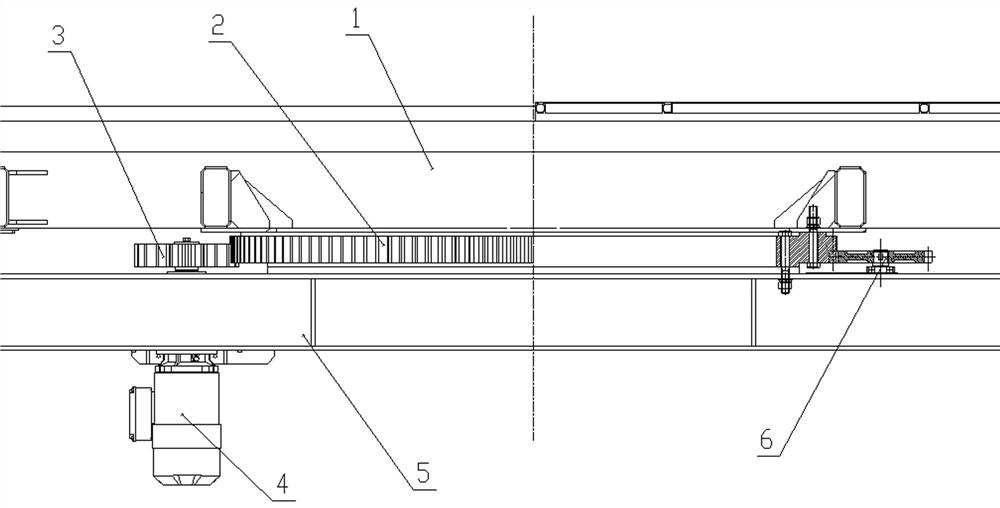

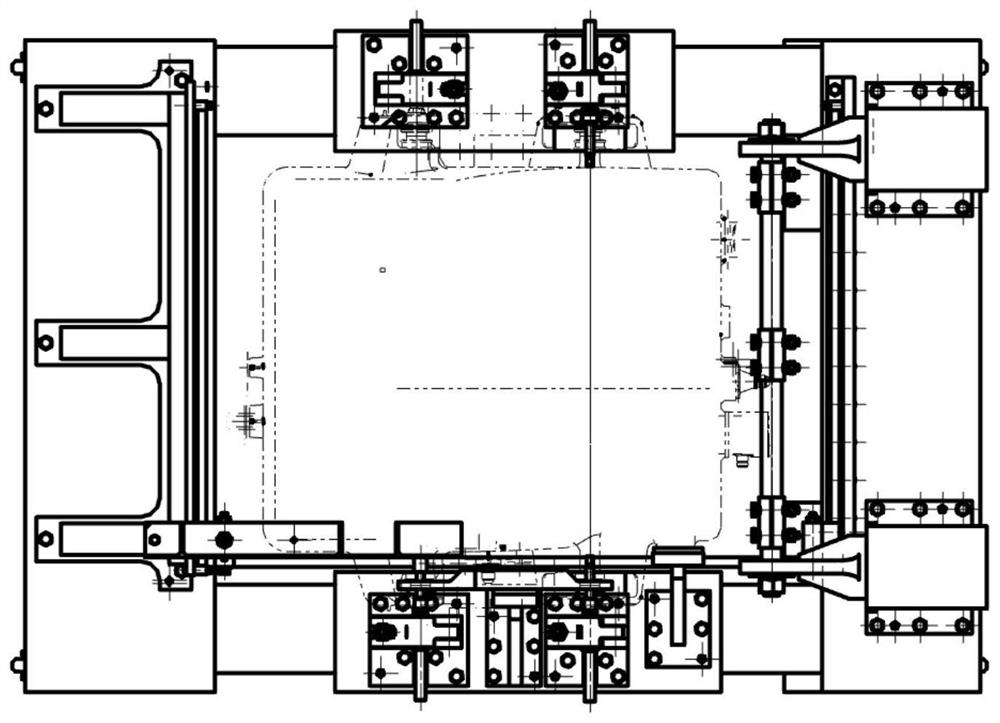

Transverse moving vehicle set for mechanical three-dimensional parking garage

PendingCN112196338APrecise control of rotational positionPrecise positioningParkingsGear wheelElectric machinery

The invention discloses a transverse moving vehicle set for a mechanical three-dimensional parking garage. The transverse moving vehicle set comprises a transverse moving vehicle steel frame, a rotating power unit, transverse moving wheel sets and transverse moving power units; the transverse moving wheel sets are arranged at the four corners of the transverse moving vehicle steel frame correspondingly, the rotating power unit is arranged on a center mounting plate of the transverse moving vehicle steel frame, and the transverse moving power units are arranged on the two sides of the transverse moving vehicle steel frame; the rotating power unit comprises a speed reducing motor, a driving gear, a transverse moving limiting wheel, a transverse moving guide rail and a transverse moving rack;transverse moving vehicle supporting wheels are installed at the bottom of the transverse moving vehicle steel frame, the transverse moving vehicle supporting wheels are matched with the rail face ofthe transverse moving guide rail in an abutting mode, and transverse moving limiting wheel is arranged at the bottom of the transverse moving vehicle steel frame; the outer edge of the transverse moving limiting wheel is embedded in the side surface of the transverse moving guide rail; and the transverse moving power units each comprise a slewing bearing, an encoder unit and a driving gear, and outer edge teeth of the slewing bearings are meshed with the encoder units and the driving gears correspondingly. According to the transverse moving vehicle set, safe and reliable conveying and receiving of vehicles are ensured, so that carrying of the three-dimensional parking garage is safer.

Owner:湖南天桥利亨停车装备有限公司

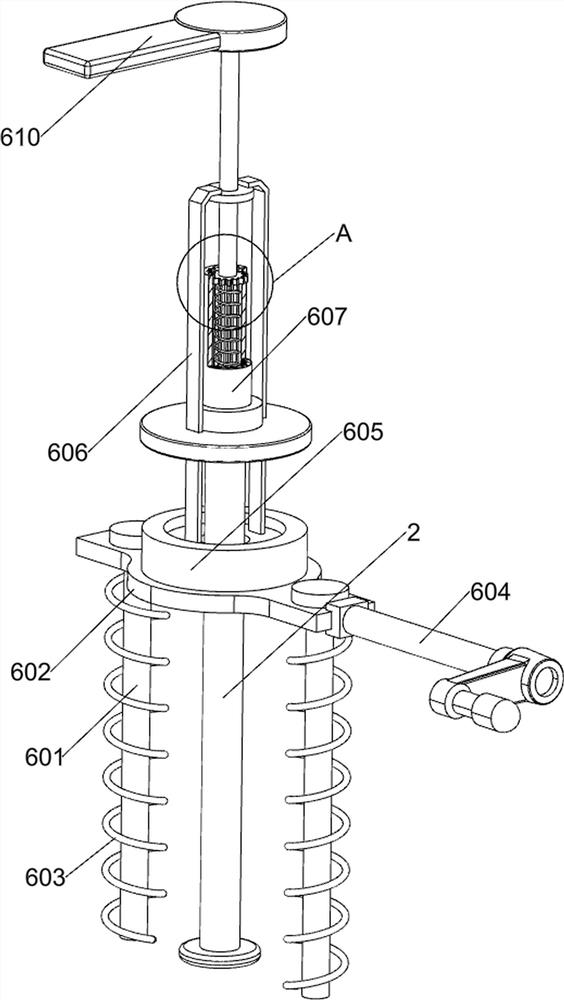

Neck myodynamia movement trainer

PendingCN112618260AImprove the effect of activitiesThe effect of the activity is goodChiropractic devicesPhysical medicine and rehabilitationElectric machinery

The invention relates to trainers and particularly relates to a neck myodynamia movement trainer. The neck myodynamia movement trainer provided by the invention is applicable to different people, enables a neck to move automatically and is convenient in operation. A technical embodiment of the invention is as follows: the neck myodynamia movement trainer comprises a base; a first bracket, wherein the first bracket is arranged at one side of the base; a lifting assembly, wherein the lifting assembly is arranged at the middle of one side of the base; a motor, wherein the motor is arranged at one side of the top of the lifting assembly; and a turning assembly, wherein the turning assembly is arranged at the upper side of the lifting assembly. The motor is started up by a person under the action of the turning assembly, an output shaft of the motor will drive a second screw rod to rotate, a first turntable will drive a first contact lever of a sliding clamp splice and a retaining cap to rotate under the action of transmission, thus, the retaining cap drives the head and neck of the person to move, the person can adjust the amplitude of turning of the retaining cap through the moving sliding clamp splice, and thus, the movement effect of the neck is better.

Owner:赖国文

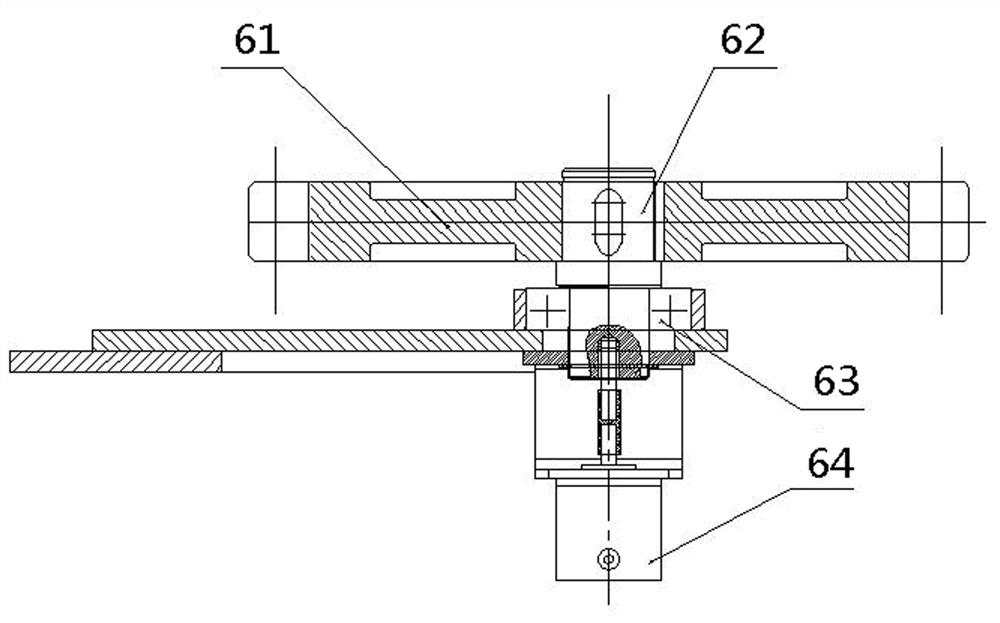

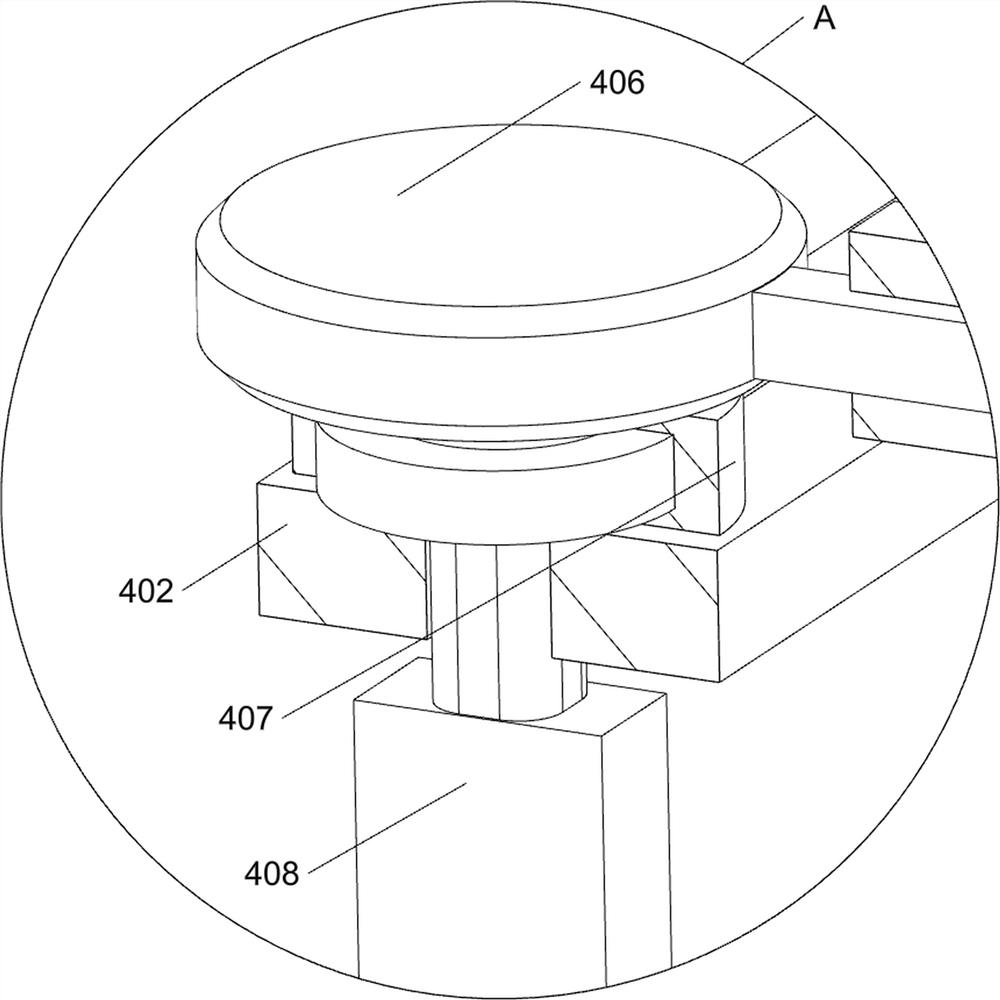

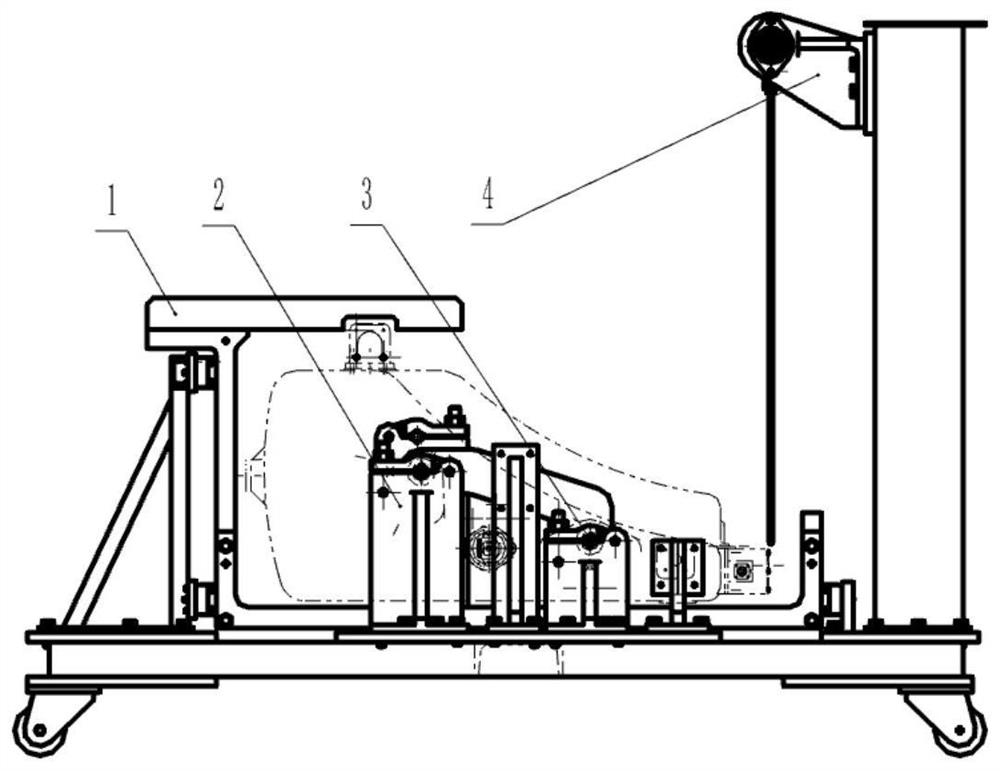

Carrier rotating device of mechanical three-dimensional parking garage

The invention discloses a carrier rotating device of a mechanical three-dimensional parking garage. The carrier rotating device comprises a carrier, a rotary slewing bearing, a rotary gear, a rotary gear motor, a transverse moving vehicle frame and a rotary encoder assembly; the carrier is installed on the upper installation face of the rotary slewing bearing, the lower installation face of the rotary slewing bearing is connected with the transverse moving vehicle frame through bolts, the rotary gear motor is installed on the transverse moving vehicle frame, and the rotary gear is installed onan output shaft of the gear motor; the rotary gear is meshed with outer edge teeth of the rotary slewing bearing to drive the rotary slewing bearing to rotate, and the rotation of the carrier can berealized; and the rotary encoder assembly is meshed with the outer edge teeth of the rotary slewing bearing to control the rotating position. The device is accurate in rotating position, the rotatingposition of the carrier can be accurately controlled through counting of the rotary encoder, safe and reliable conveying and receiving of the vehicle are guaranteed, and carrying of the three-dimensional parking garage is safer.

Owner:湖南天桥利亨停车装备有限公司

Burr removing equipment for junction box production

The invention relates to burr removing equipment, in particular to burr removing equipment for junction box production. According to the burr removing equipment for the junction box production, burrs are automatically scraped, the scraping effect is uniform, and operation is convenient. According to the technical solution, the burr removing equipment for the junction box production comprises a base, a first bracket arranged at the upper part of one side of the base, an object storage rack rotationally arranged on one side of the upper part of the first bracket, a scraping assembly arranged on one side of the upper middle part of the base, and a clamping assembly arranged at the top of the object storage rack. Under the action of the scraping assembly, the junction box is placed in the middle of the top of the object storage rack, a first connecting rod is moved to the rear side, the first connecting rod can drive a first sliding block, a first supporting frame and a first sliding sleeve to move to the rear side, the first sliding sleeve can drive a chamfering tool to move, when the chamfering tool makes contact with the junction box, the burrs on one side of the junction box can be removed, and the efficiency of people is improved.

Owner:肖琼

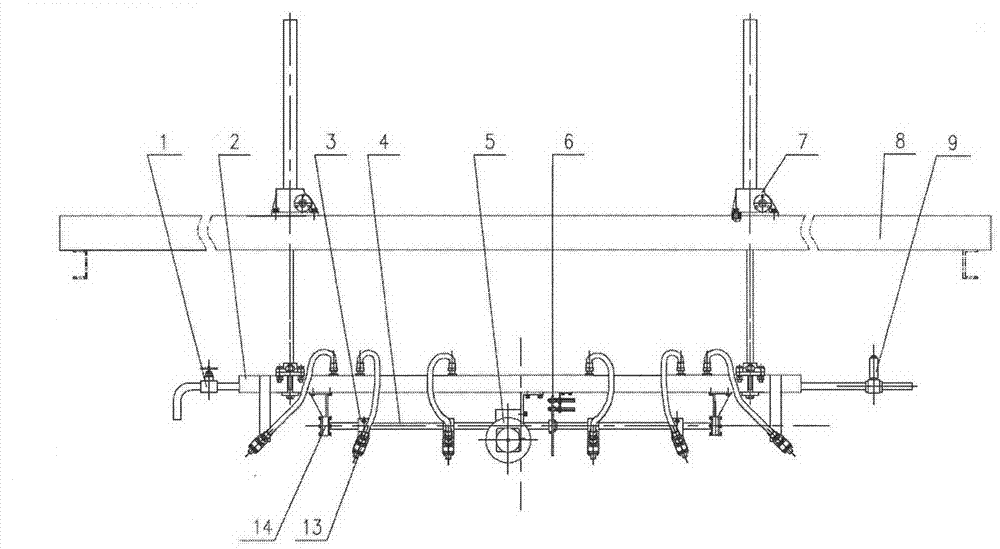

Vertically lifting type antifreeze solution spraying device and use method thereof

ActiveCN102266827BOptimize locationEfficient and uniform sprayingLiquid surface applicatorsLiquid spraying apparatusControl systemSpray nozzle

Owner:TAIYUAN UNIV OF TECH

a shaft

ActiveCN105041843BReduce the number of gapsAvoid missingCasings/cabinets/drawers detailsPivotal connectionsEngineeringMachining

The invention discloses a hinge. The hinge comprises a first rotary piece, a second rotary piece and a protective piece. The first rotary piece comprises a first connecting piece, a first rotary shaft and a first shaft sleeve. The second rotary piece comprises a second connecting piece, a second rotary shaft and a second shaft sleeve. The hinge is formed by splicing the first rotary piece, the second rotary piece and the protective piece. The protective piece of the proper length can be adopted for reducing the number of gaps between the first rotary piece, the second rotary piece and the protective piece, the gaps even can be prevented from being generated, and the technical effect that liquid matter in electronic equipment can be effectively prevented from leaking is achieved. Due to the fact that the hinge special for the electronic equipment can be composed of components which are lower in machining difficulty and simple in splicing manner, the technical effects that the production cost is effectively reduced and production and machining efficiency is improved are achieved.

Owner:LENOVO (BEIJING) LTD

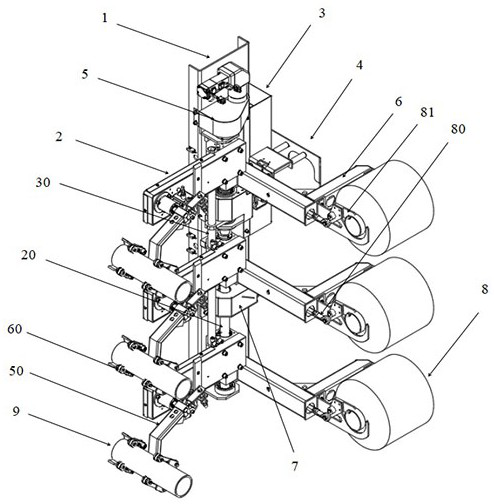

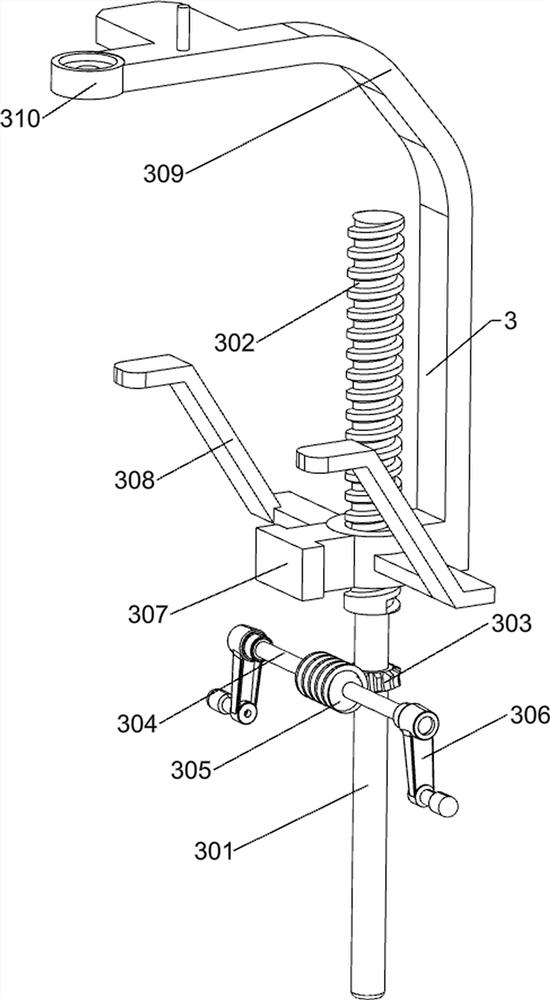

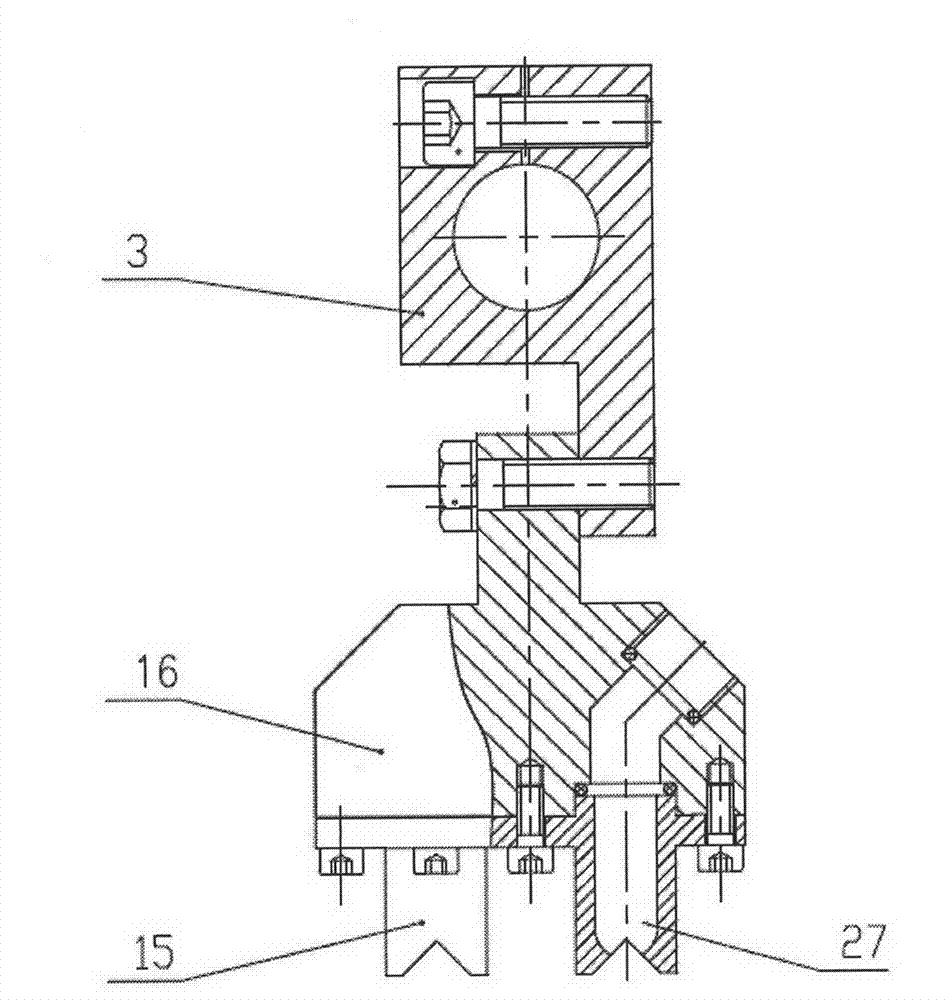

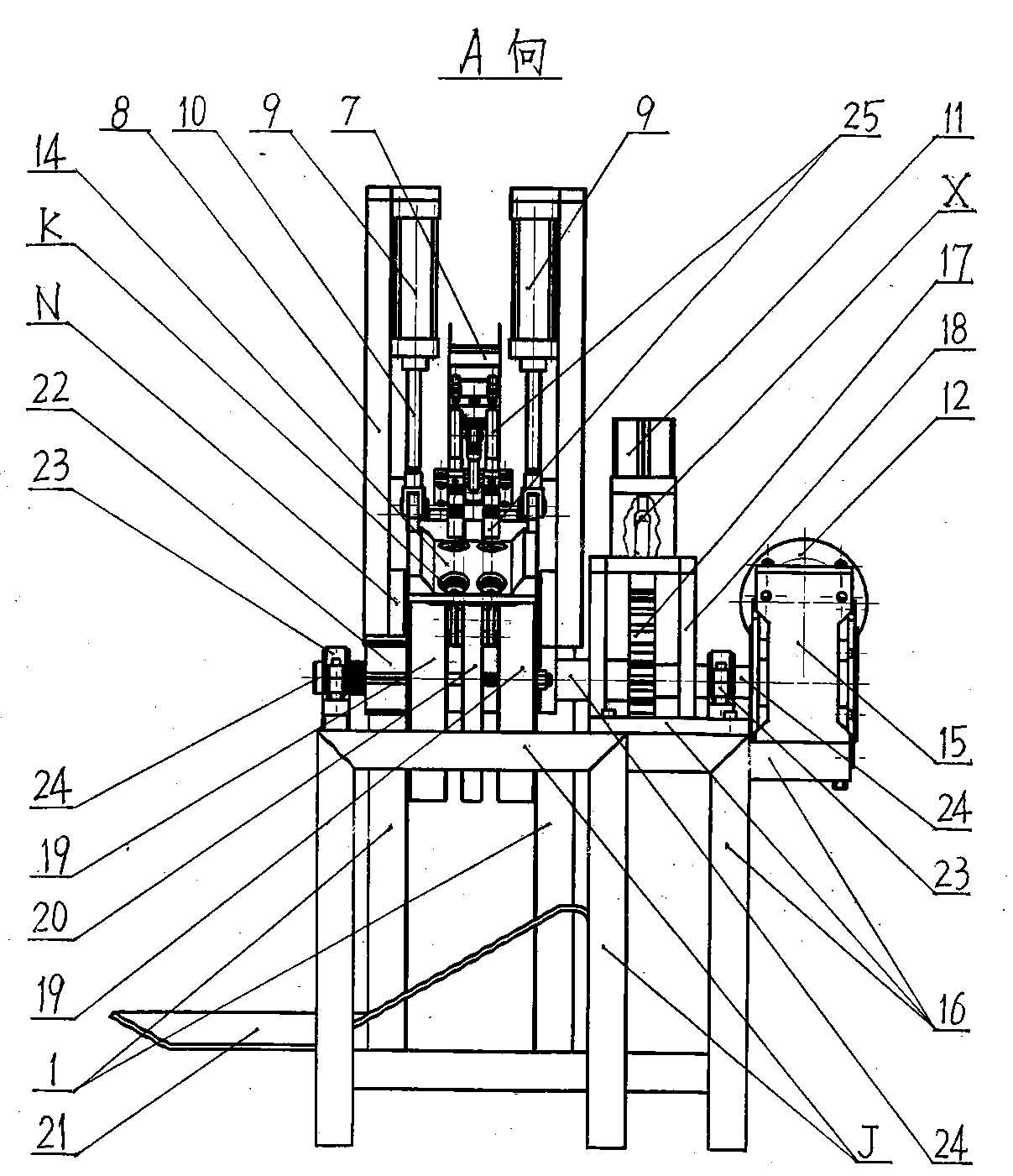

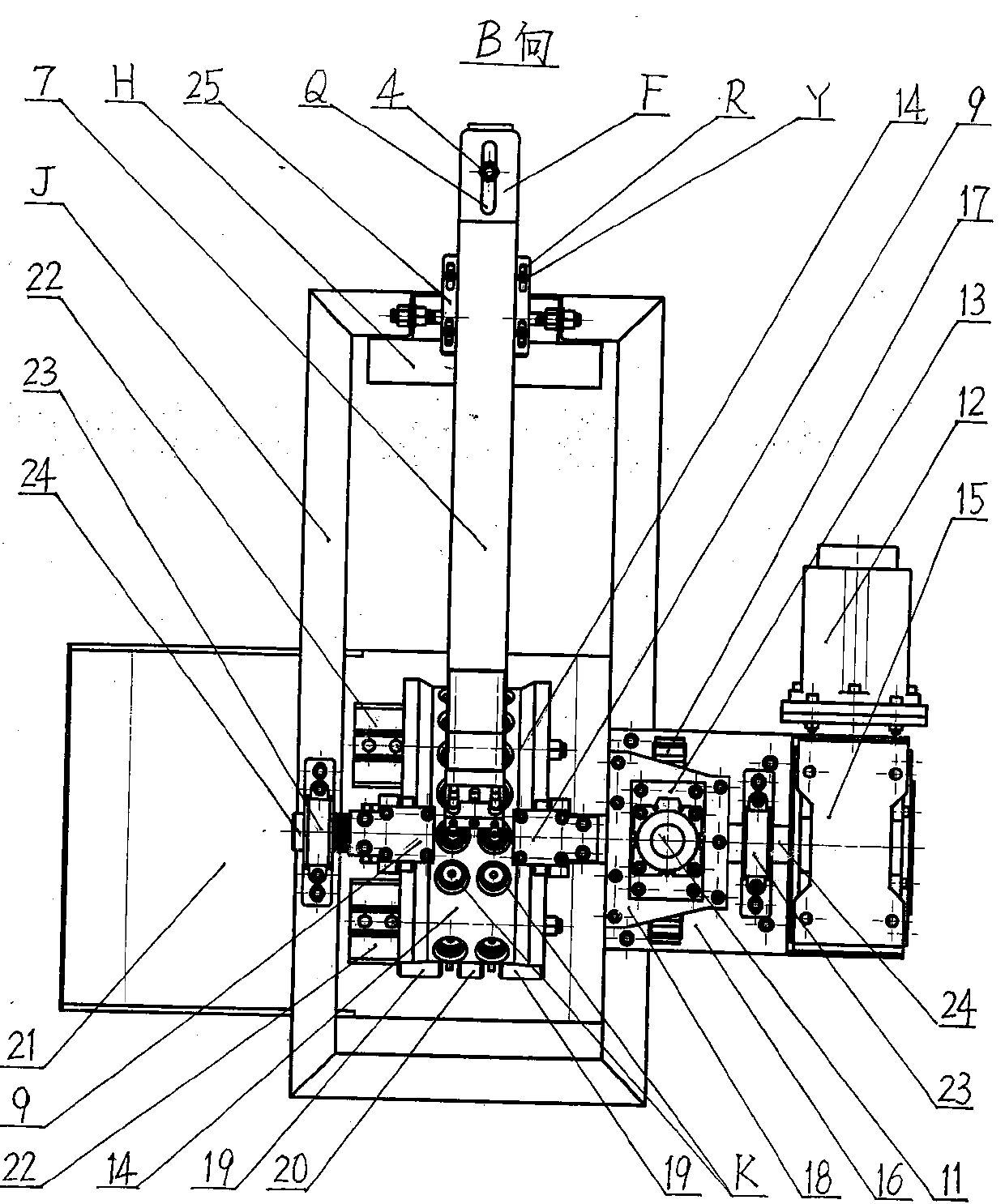

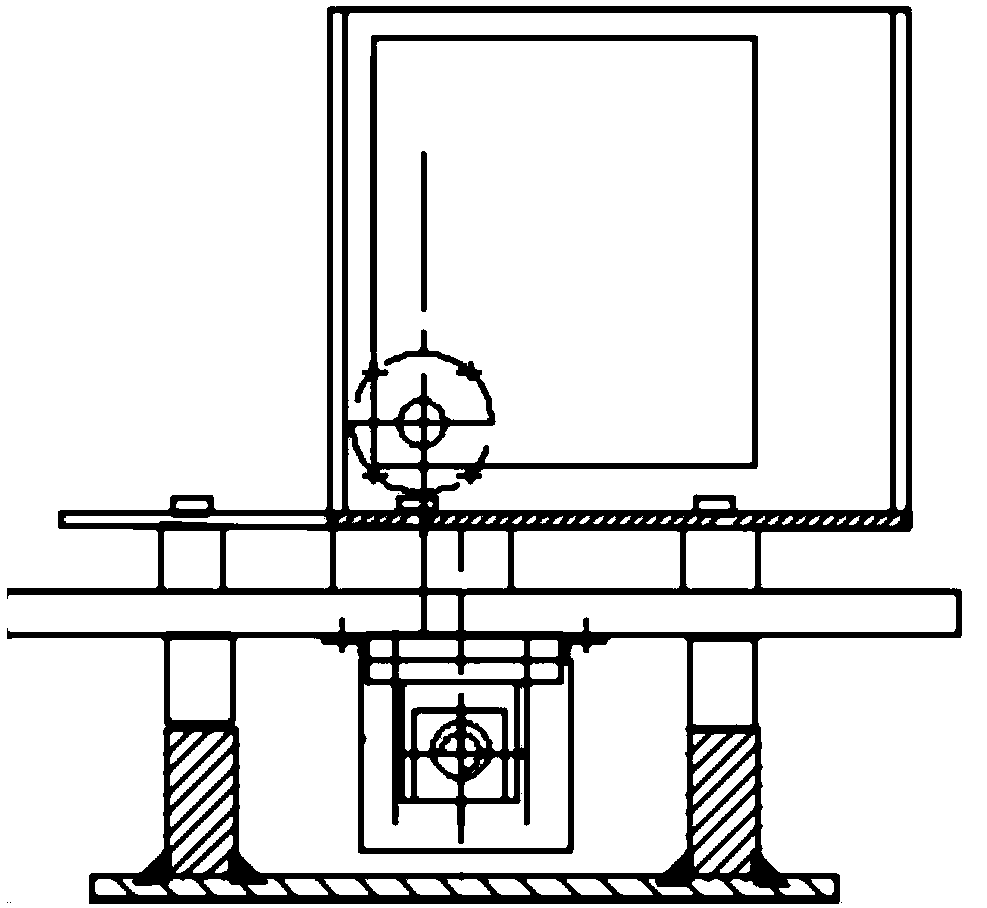

Plug welding hole welding device for stamping and welding shoe for automobile brake

PendingCN107866654APrecise rotational positionEliminate relative position errorsWelding/cutting auxillary devicesAuxillary welding devicesBump bondingBrake shoe

The invention relates to a plug welding hole welding device for a stamping and welding shoe for an automobile brake. A gland cylinder (9) is arranged on a gland cylinder frame (8), and a gland cylinder rod (10) is connected downwards with a gland (14) to compress a panel workpiece; two clamping cylinders (22) are arranged side by side on the left end face of a workpiece clamping wheel; a speed reducer (15) is connected with a motor (12) and is arranged on a speed reducer support (16); a main shaft (24) connected with the speed reducer (15) is fixedly provided with a pilot gear (17) and the workpiece clamping wheel in a sleeving way, and the pilot gear (17) is arranged in a gear protection holder (18); a pilot pin (X) arranged on a cylinder rod of a pilot cylinder (11) is matched with the pilot gear (17); a welding gun rack (7) is vertically erected on a welding gun rack support (1) and a welding gun rack cylinder (2); a welding gun (25) corresponds to the gland (14). The plug welding hole welding device provided by the invention is controlled by an electronic control pneumatic system to weld a plug welding hole (K) of the panel workpiece. The plug welding hole welding device provided by the invention has the advantages of high degree of automation, low noise, low energy consumption, reduced pollution, reduced cost and high production efficiency.

Owner:山东力得汽车科技股份有限公司

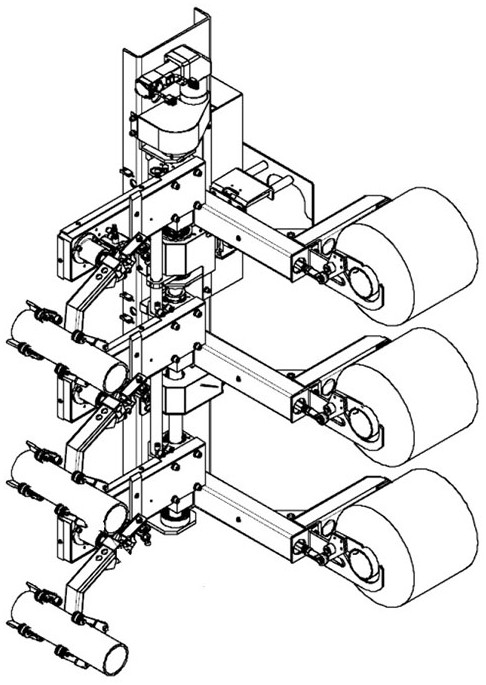

Automatic drilling device for multi-standard pipe fittings

ActiveCN106881472BReduce frictionPrecise rotational positionFeeding apparatusLarge fixed membersFriction reductionRolling resistance

The invention discloses an automated drilling device for pipes of multiple specifications. The automated drilling device comprises a base. The automated drilling device is characterized in that an output shaft of a longitudinal servo motor is linked with a ball screw, and the ball screw is supported by bearings and assembled onto the base; a workbench is further arranged above the base; a rolling guide rail is arranged between the workbench and the base; a mechanism for driving a conical clamp to rotate is arranged on the workbench; and the mechanism comprises support frames, a rotating servo motor, a reducer and a center height adjusting device. The device is provided with multiple adjustment mechanisms, and multiple holes can be drilled in the circumferential faces of the pipes large in length and diameter change range; the pipes move and rotate in the form of rolling friction, friction is reduced, rotation positions and movement positions are precise, and positional precision of all the holes drilled in the pipes is obviously improved; mounting of the pipes is completed one time, and the pipes do not need to be loosened in the intermediate process; and automation is achieved in the whole drilling process, and efficiency is obviously improved.

Owner:江苏三升信电子工程有限公司

Inspection device and method for quickly eliminating size error and quickly clamping large lubricating oil tank

ActiveCN113432508AGuaranteed movement accuracyEliminate the effect of size errorMechanical counters/curvatures measurementsControl engineeringProcess engineering

The invention discloses an inspection device and method for quickly eliminating size errors and quickly clamping a large lubricating oil tank, and the inspection device uses four positioning pin shafts to cooperate with four fixed clamping supports to convert a positioning surface to the outer side of a semi-enclosed structure, and uses the four positioning clamping supports to quickly align an installation position, and then a detection sample plate assembly and a sample plate are pushed to realize contour dimension detection in two directions of linear translation and rotation. The problems that a large lubricating oil tank product is heavy in weight and large in size are solved, positioning is simple and reliable, the influence caused by position tolerance (errors) of mounting holes in the large lubricating oil tank is effectively eliminated, and operation is easy and convenient.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

A step-by-step wire tapping device for earmarking plastic parts

ActiveCN107999897BImprove coherenceStepping wire implementationPrecision positioning equipmentThread cutting feeding devicesEar tagElectric machinery

The invention discloses a stepping tapping device for an ear tag injection molded part. The stepping tapping device comprises a base plate, a motor, a rocker, a driving rod and a turntable frame; a limiting guide support is arranged at the corner of the base plate; a guide column is arranged on the limiting guide support; a pneumatic tapping machine is arranged in the middle of the edge of the base plate; the motor is connected to the lower end of the base plate through bolts; one end of the rocker is connected to an output shaft of the motor, and the other end of the rocker is hinged to the lower part of the drive rod; a long groove is formed in the driving rod and can slide under the limit of the guide column; and the turntable frame is connected to the base plate in a rotating mode. Thestepping tapping device has the advantages that the stepping tapping operation can be carried out after a male ear tag body is subjected to injection molding, the tapping efficiency is high, the thread consistency is good, and the adjustment of changing the thickness of a tag pole of the male ear tag body can be facilitated.

Owner:HEBEI BOCHEN HUSBANDRY TECH CO LTD

Method and device for tracking control of solar electrical energy generation

InactiveCN101592969BSimple and fast operationPrecise rotational positionPhotovoltaic supportsControl using feedbackAutomatic controlElectrical battery

Owner:SHENZHEN NENGLIAN ELECTRONICS +1

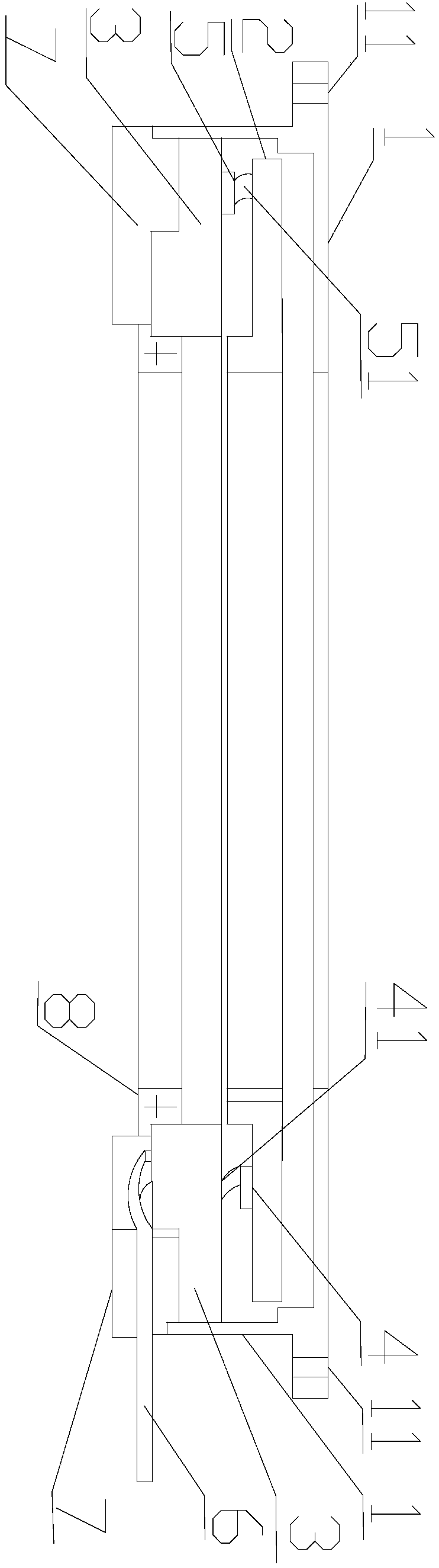

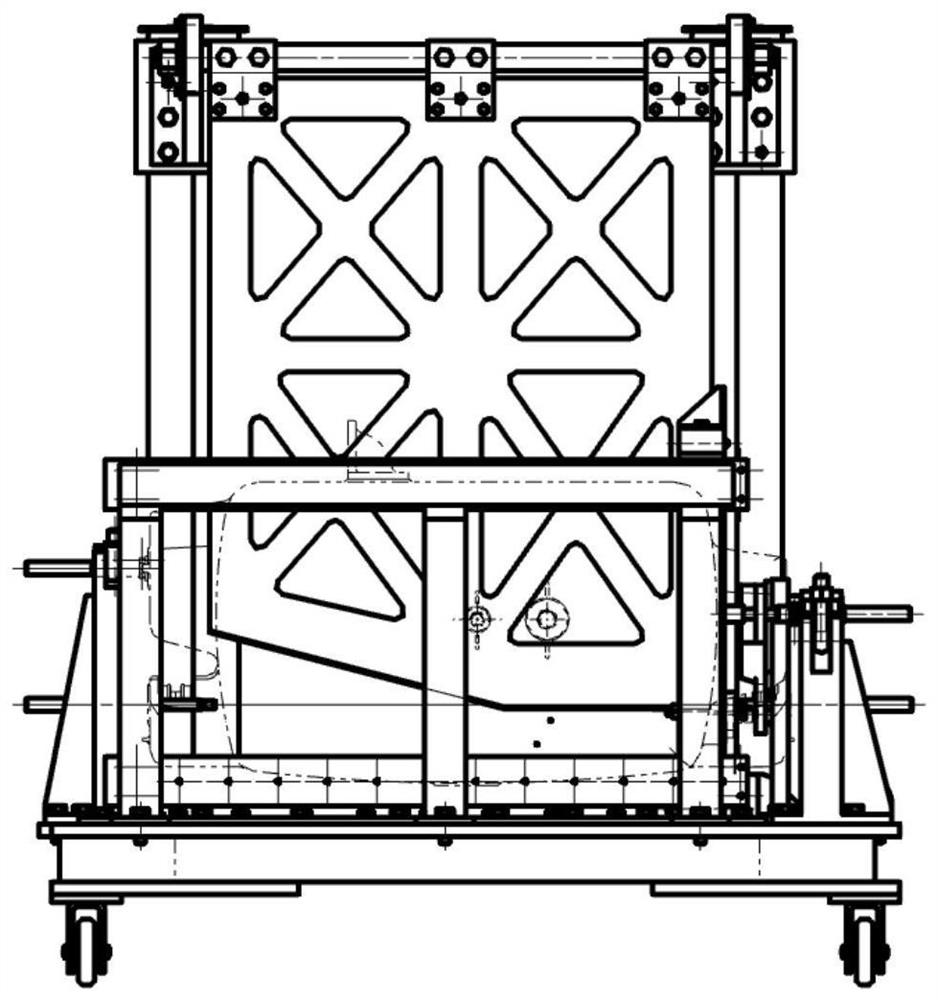

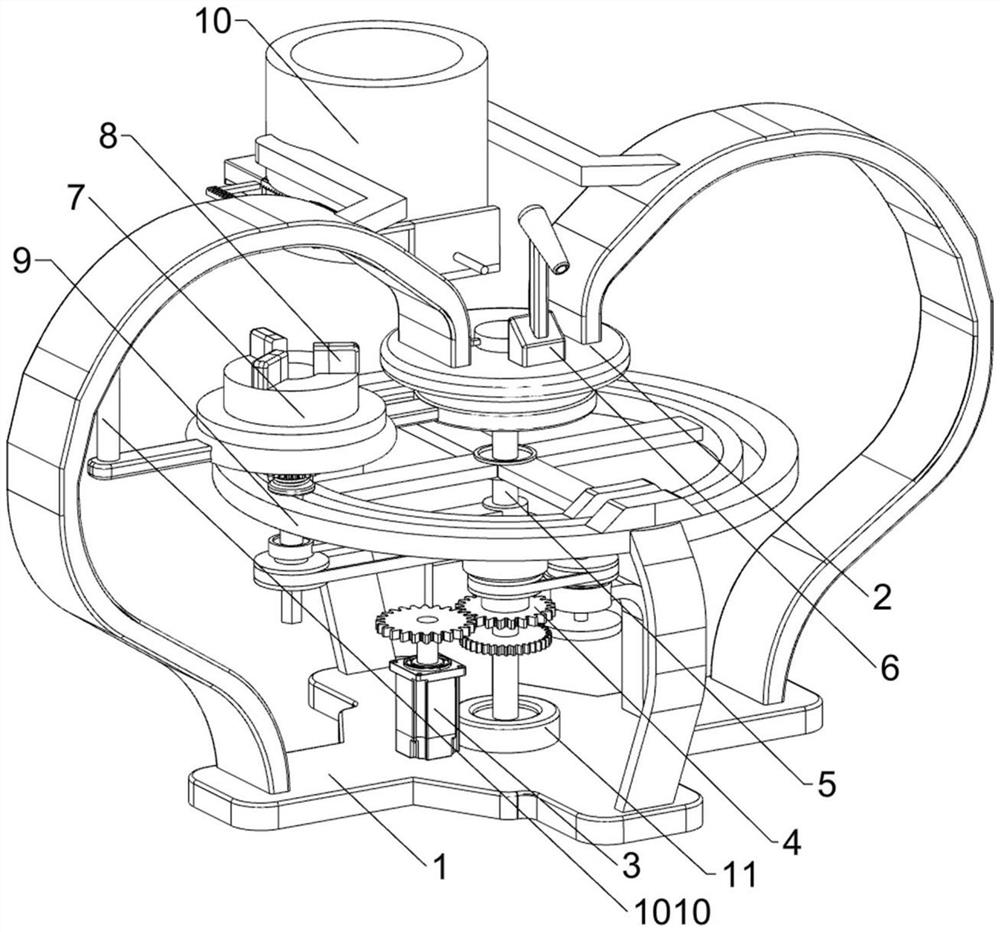

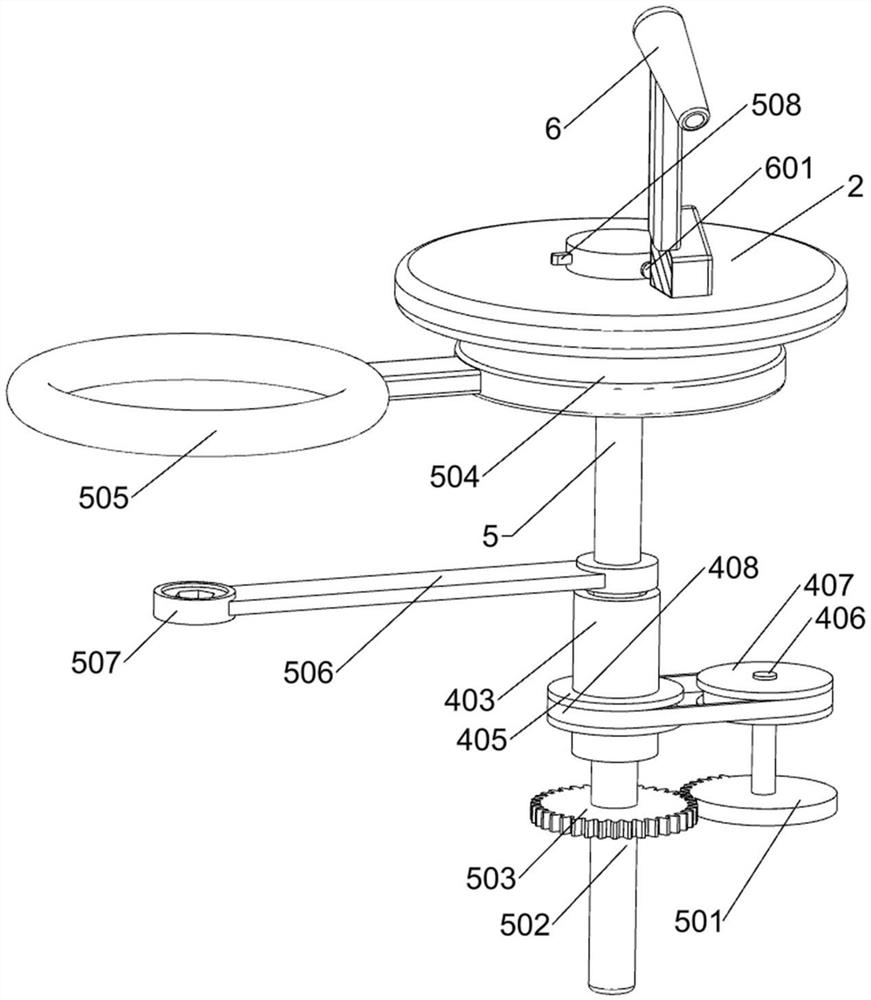

Automatic stair table installing equipment

ActiveCN111633425AGood linkageHigh degree of automationAssembly machinesMetal working apparatusEngineeringStructural engineering

The invention provides automatic stair table installing equipment, and belongs to the technical field of mechanical assembling. The automatic stair table installing equipment comprises an end cover disc clamping rotation device, a stair table plug press device, an O-shaped ring clamping sleeving device and a linkage device. The end cover disc clamping rotation device comprises an end cover disc, an end cover disc left clamping mechanism and an end cover disc right clamping rotation mechanism. The stair table plug press device comprises a stair table supply mechanism and a stair table plug press mechanism. The O-shaped ring clamping sleeving device comprises an O-shaped ring supply mechanism and an O-shaped ring sleeving mechanism. The linkage device comprises a linkage drive mechanism, a plug press linkage mechanism and an O-shaped ring supply linkage mechanism. By means of the automatic stair table installing equipment, a stair table can be automatically plugged into a stair table installing groove in an end cover disc, an O-shaped ring can be automatically sleeved with an O-shaped ring installing groove in the end portion of the stair table, automatic stair table installation isfinished, linkage performance is good, the automation degree is high, and the assembling efficiency is greatly improved.

Owner:胡佳威

A high-reflectivity powder coating spraying equipment for lamp production

ActiveCN112808545BImprove work efficiencyEasy to unloadLiquid surface applicatorsCoatingsElectric machineEngineering

The invention relates to a spraying equipment, in particular to a high-reflectivity powder coating spraying equipment for lamp production. The technical problem of the present invention is to provide an automatic spraying lamp, a high-reflectivity powder coating spraying equipment for lamp production with good spraying effect and simple operation. The technical solution of the present invention is a high-reflectivity powder paint spraying equipment for lamp production, including: a base; a first support plate, the first support plate is provided in the upper middle of the base; a motor is provided on one side of the upper middle of the base; The transmission assembly is provided with a transmission assembly on one side of the upper middle part of the base. The beneficial effect is: under the action of the intermittent rotating component, people place the lamp on the shelf, start the motor, and after a series of transmissions, the third transmission rod will drive the first contact rod to rotate 90 degrees, and the first contact rod will rotate 90 degrees. When in contact with the touch switch, the nozzle will spray the paint onto the lamp, which effectively improves people's work efficiency.

Owner:济南汇金电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com