Automatic drilling device for multi-standard pipe fittings

A drilling device and multi-specification technology, applied in the field of automatic drilling devices for multi-specification pipe fittings, can solve the problems of inability to realize automatic processing, cumbersome manual drilling operations, and complicated use, and achieve improved position accuracy, efficiency, and processing efficiency. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

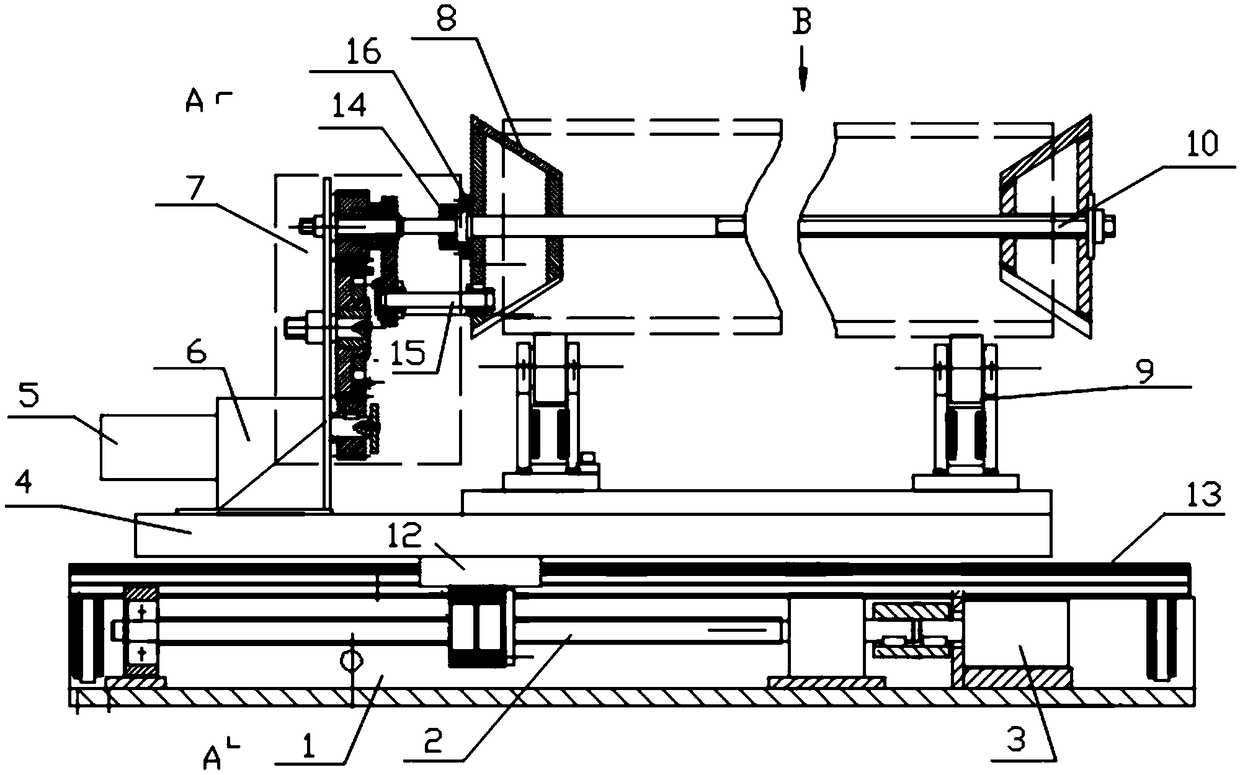

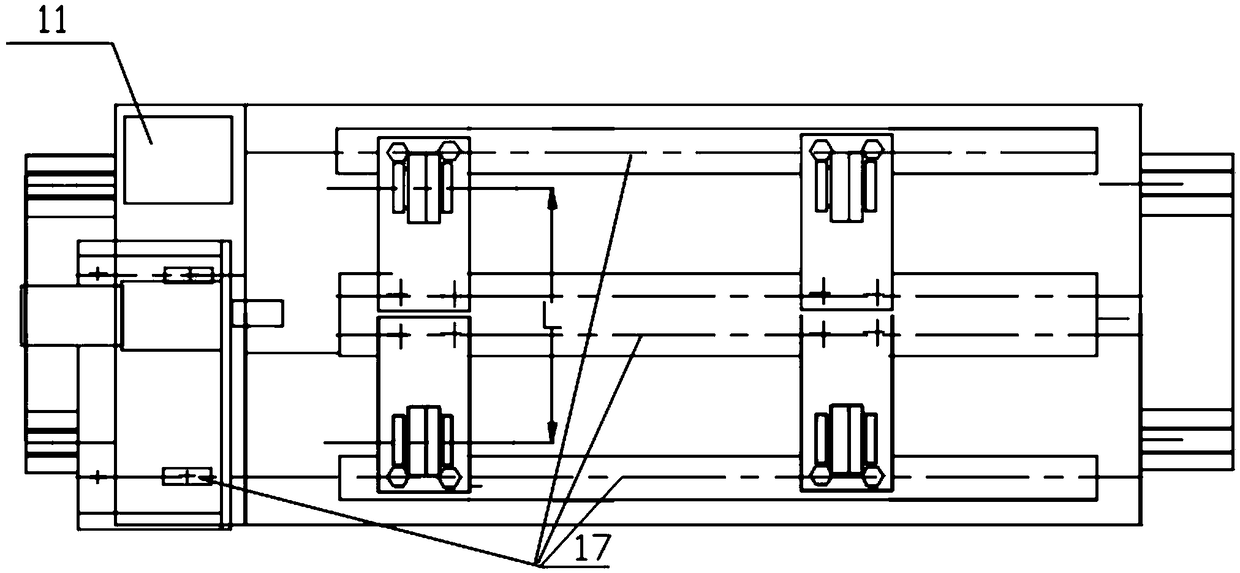

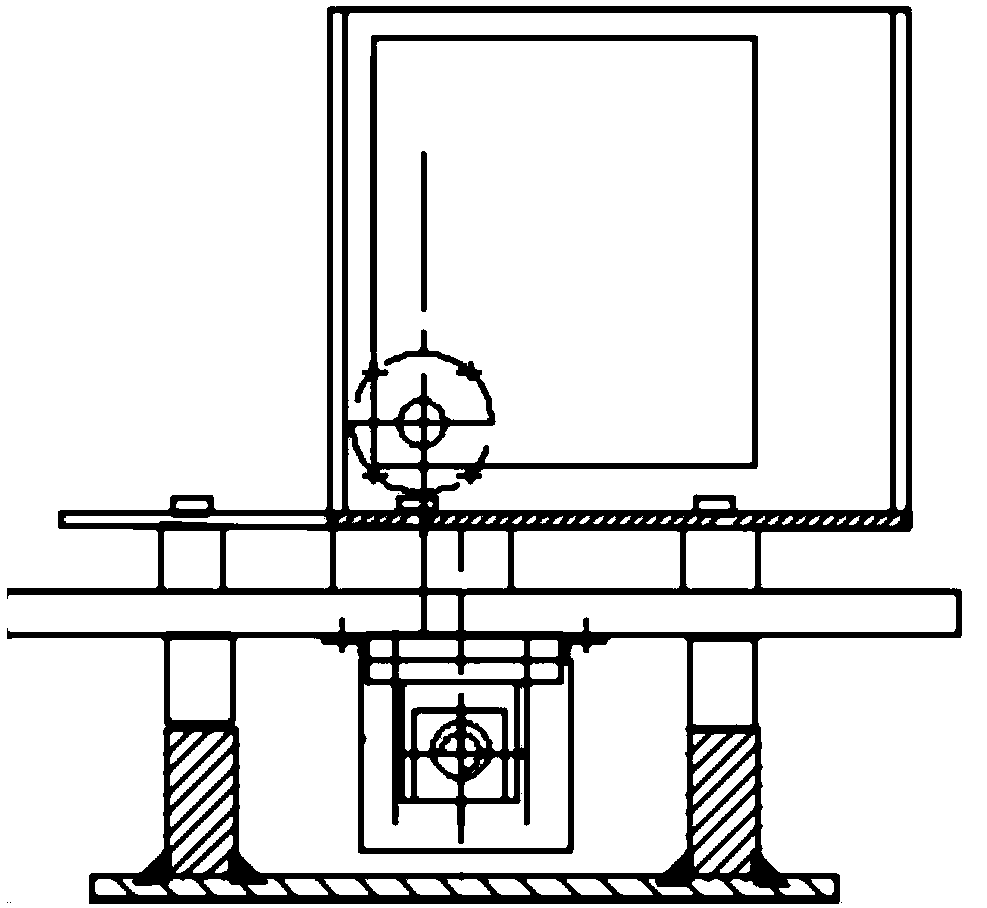

[0042] Such as Figures 1 to 3 , the output shaft of the longitudinal servo motor 3 is connected with the ball screw; the ball screw is supported by two bearings, installed on the base 1, and connected with the workbench 4 through the nut seat 12. When the vertical servo motor 3 drives the ball screw 2 to rotate, the nut seat 12 cannot rotate because it is fixed on the workbench 4, and the nut seat 12 will drive the workbench 4 to move longitudinally. A rolling guide rail 13 is provided between the workbench 4 and the base 1 , so that the workbench 4 can relatively move relatively easily and accurately on the base 1 . After drilling a hole, the digital control system 11 sends an instruction to make the longitudinal servo motor 3 drive the workbench 4 to move to the next drilling position.

[0043] The digital control system 11 is an accessory system specially designed for realizing the action of the device, and it controls the action of the device of the present invention and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com