Polyurethane material shaping and cutting device for new energy automobile

A polyurethane material and new energy vehicle technology, applied in metal processing and other fields, can solve problems such as injuries, reduced work efficiency, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

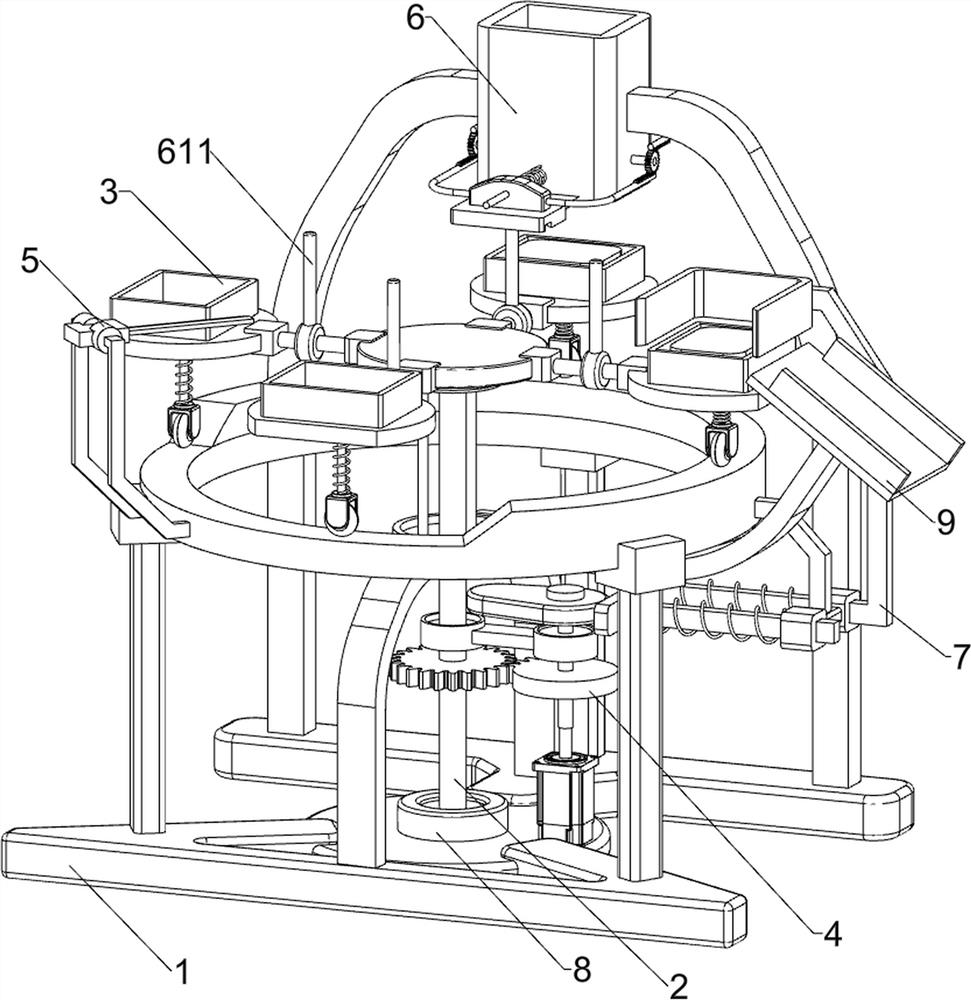

[0029] A polyurethane material shaping cutting device for new energy vehicles, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a first support frame 2, a charging assembly 3, a transmission assembly 4 and a belt cutter 5. The middle part of the base 1 is rotatably provided with a first support frame 2, and the first support frame 2 and the base 1 A charging assembly 3 is arranged between them, a transmission assembly 4 is arranged on the right side of the middle part of the base 1, and a belt cutter 5 is arranged on the left front side of the upper part of the charging assembly 3.

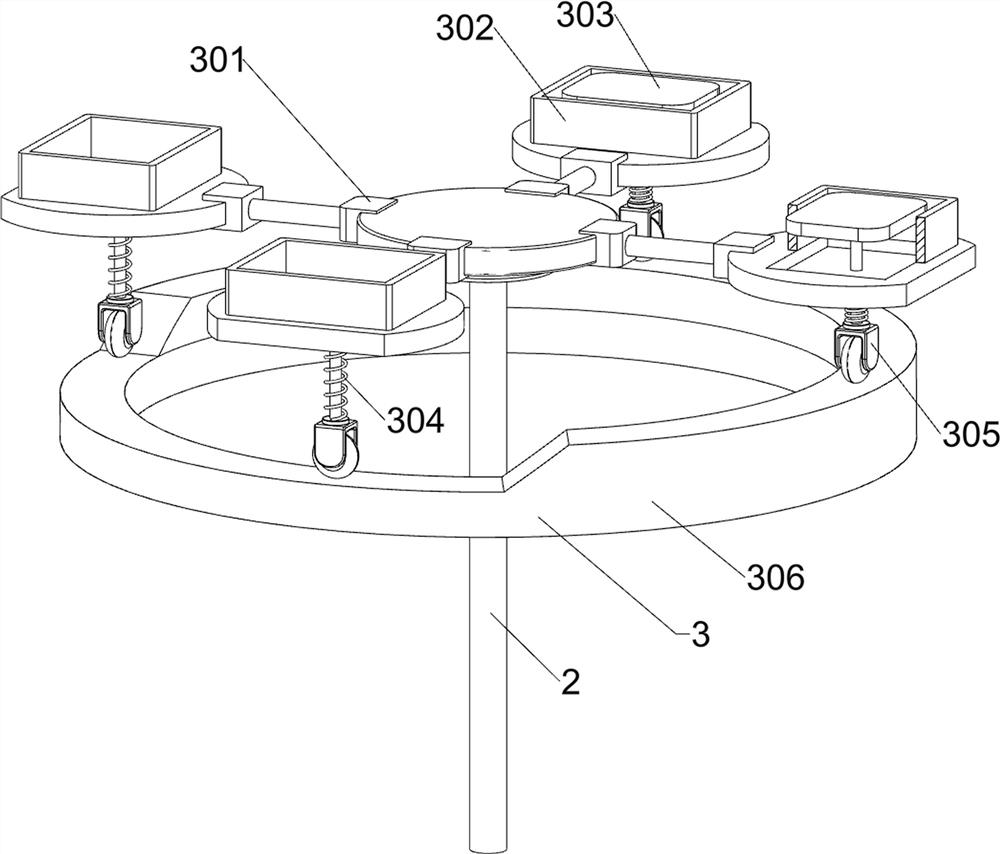

[0030] The charging assembly 3 includes a first connecting rod 301, a first baffle plate 302, a top plate 303, a first spring 304, a roller 305 and a contact frame 306, and the first supporting frame 2 top is provided with a first connecting rod 301 around the top. The outer sides of the connecting rods 301 are provided with a first baffle 302, the first baffle 302 is pr...

Embodiment 2

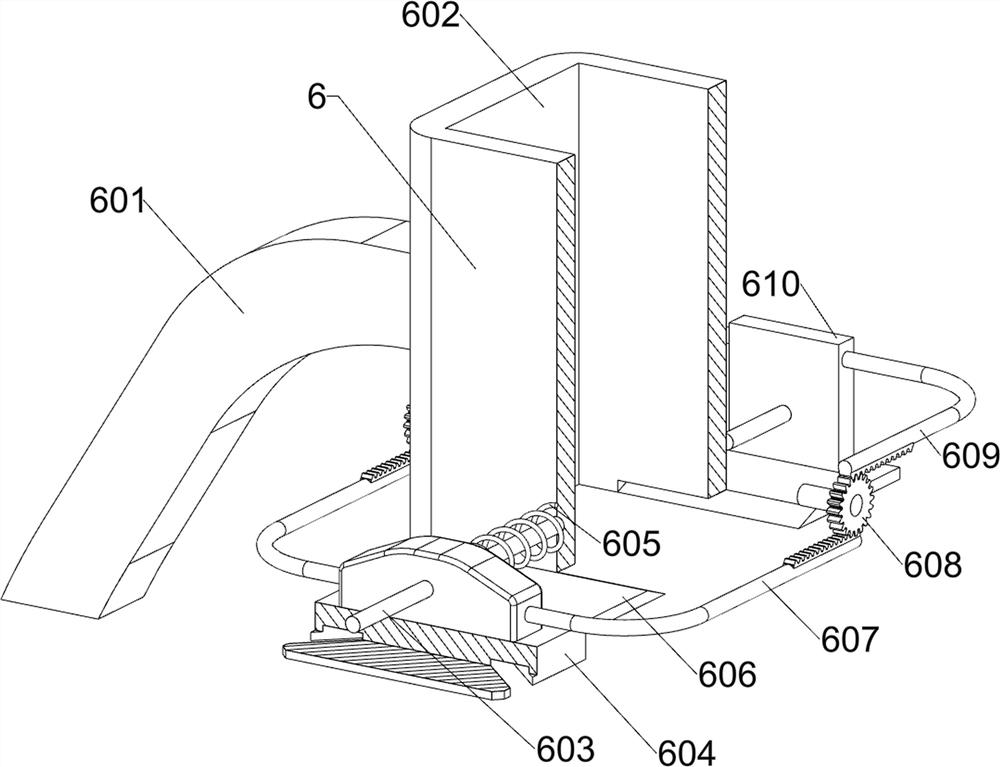

[0034] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a blanking assembly 6 is also included, including a first bracket 601, a blanking cylinder 602, a first guide rod 603, a movable plate 604, a second spring 605, a second baffle plate 606, a first rack 607, The second gear 608, the second rack 609, the support plate 610 and the contact rod 611, the rear side of the base 1 is symmetrically provided with the first bracket 601, and the top of the first bracket 601 is provided with a blanking tube 602, and the blanking tube 602 The lower side is symmetrically provided with a first guide rod 603, and the front side of the first guide rod 603 is slidably provided with a movable plate 604, and a second spring 605 is connected between the movable plate 604 and the blanking cylinder 602, and the second spring 605 Set on the first guide rod 603 on the front side, the left and right sides of the movable plate 604 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com