Linear roller bearing

一种线性滚动轴承、支承槽的技术,应用在直线运动的轴承、轴承、轴和轴承等方向,能够解决线性滚动轴承故障损坏、干扰运行噪音等问题,达到消除歪斜的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

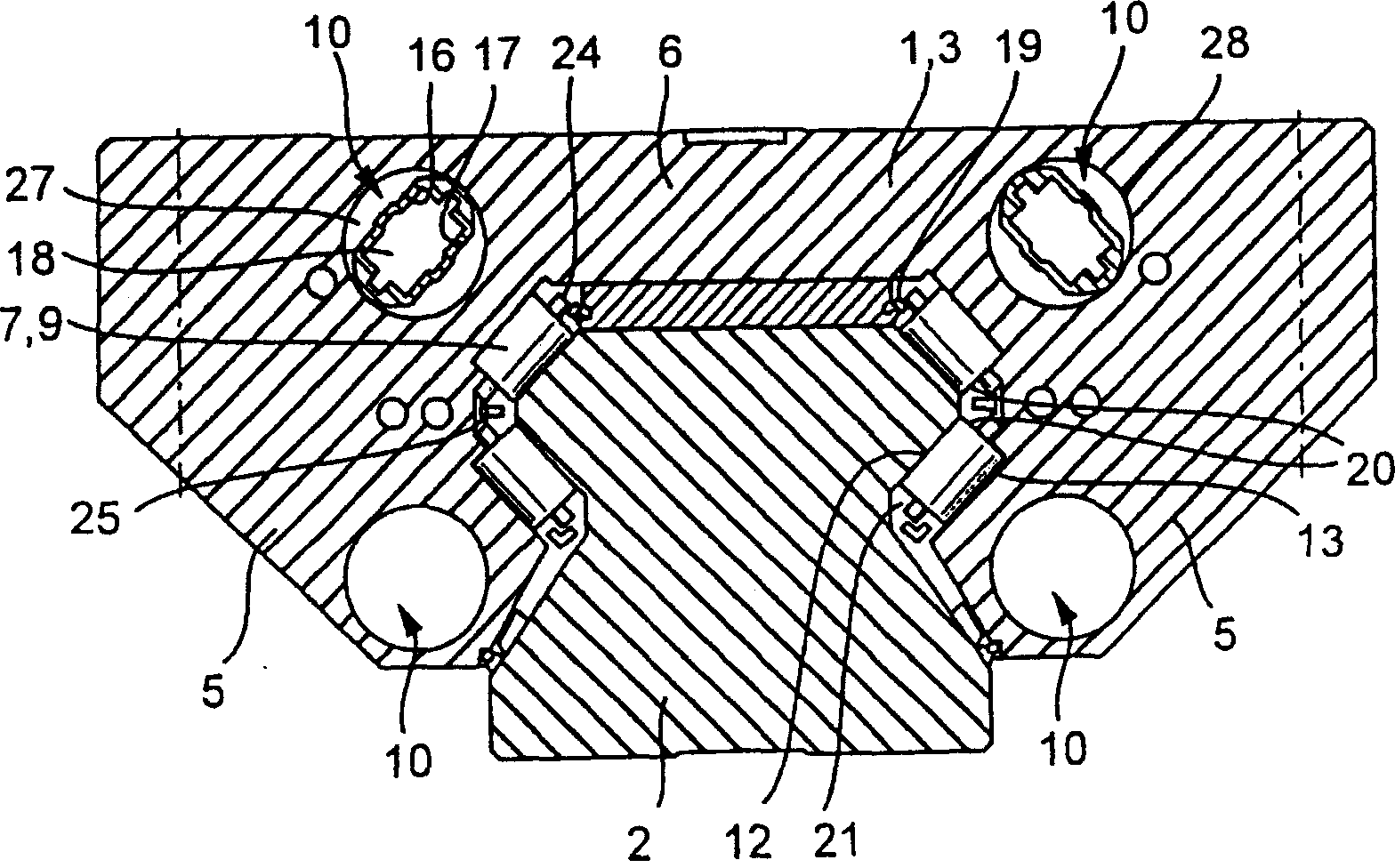

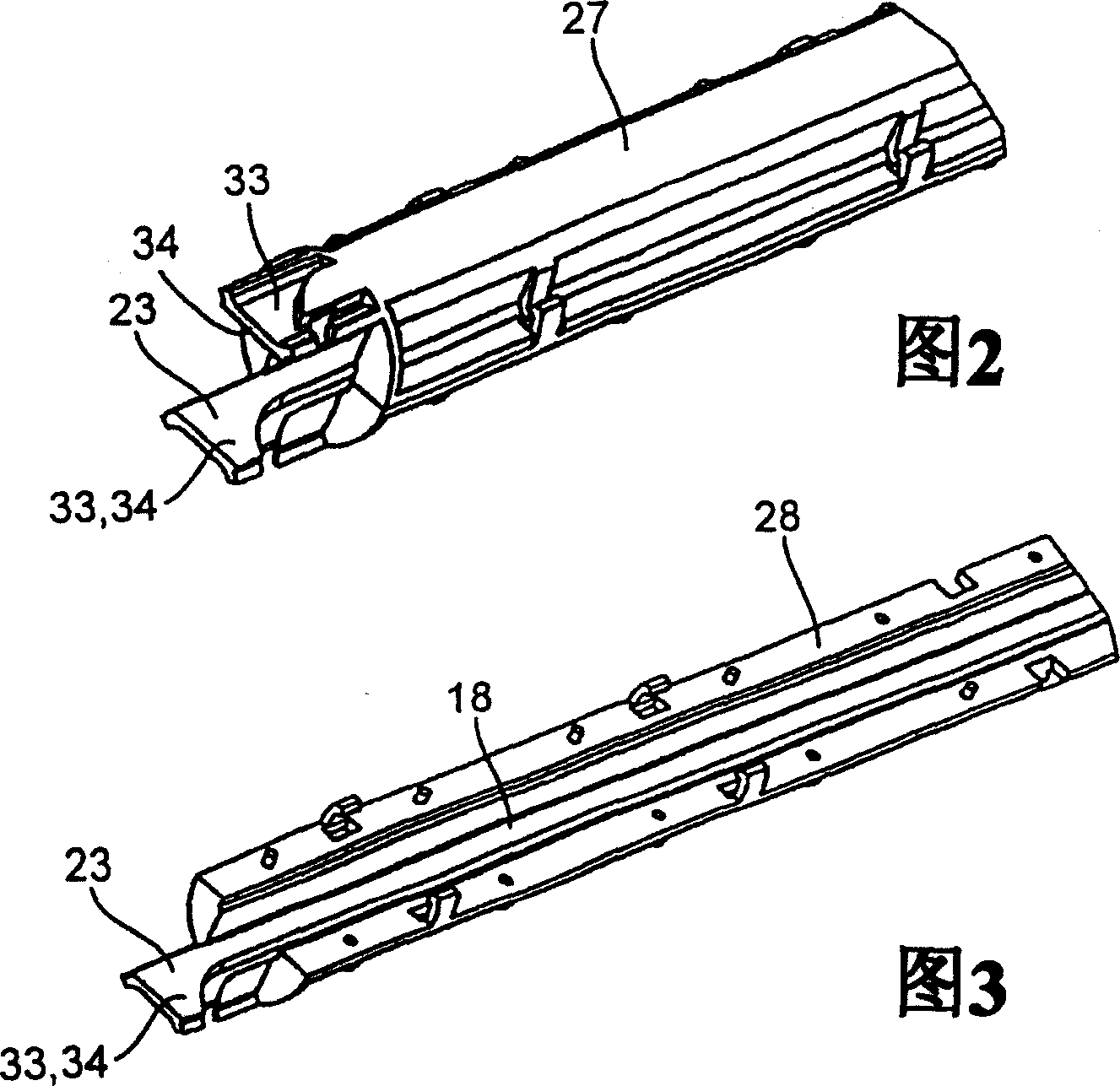

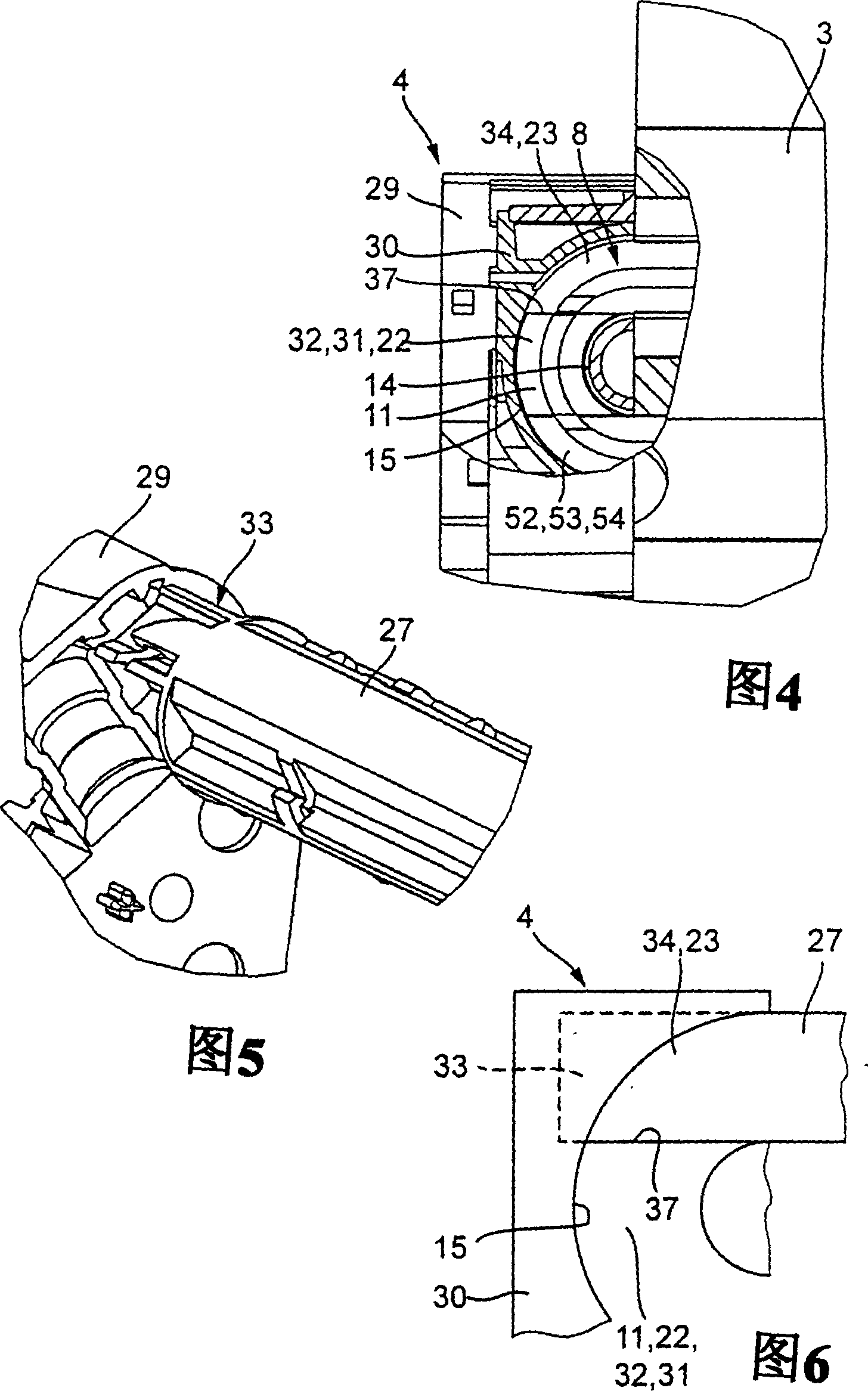

[0027] figure 1 A cross-section through a linear guide according to the invention is shown with a guide carriage 1 rolling on a guide rail 2 . The guide carriage 1 comprises a support 3 and an end part 4 (see FIG. 4 ), wherein the end part 4 is fixed on both sides of the support 3 . The support 3 has two guide arms 5 and a connecting web 6 which is integrally connected to the two guide arms 5 , specifically in the form of a U-shaped support. The guide slide 1 is supported on the guide rail 2 by the longitudinal movement of the roller 7 . Rollers 7 are arranged in roller grooves 8 . Each roll groove 8 comprises a support groove 9 supporting the roller 7 , a return groove 10 returning the roller 7 and two turning grooves 11 interconnecting the support groove 9 and the return groove 10 . The roller groove 8 has guide rails 12 , 13 , 14 , 15 , 16 , 17 for the rollers 7 . The guide rail 12 is formed on the guide rail 2 . Two such guide rails 12 are arranged on each longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com