A kind of manufacturing method of bulletproof ceramic plate

A manufacturing method and ceramic technology are applied in the field of forming and preparing bulletproof ceramic inserts, which can solve the problems of bulletproof inserts being easy to stick to molds, threats to soldiers' lives, and difficulty in making molds, and achieve low cost, enhanced bonding effect, and adhesiveness. The effect of increasing the area

Active Publication Date: 2019-10-01

NINGBO VULCAN TECH CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method is usually small pieces of bulletproof ceramic pieces spliced into a whole bulletproof plate, and the bulletproof insert plate made of this small piece of ceramic splicing method becomes the weak point of bullet penetration at the seam of small pieces of ceramic pieces. The peeling off of the ceramic sheet and the polyethylene sheet will become a fatal defect and pose a serious threat to the lives of soldiers.

At present, there are also attempts to make the whole bulletproof insert plate by molding it with a mold, so that the surface is a little rougher, and the adhesive area is increased to a certain extent, so that the bond with the polyethylene plate is stronger, but the mold is extremely difficult and expensive to manufacture. High; secondly, the entire bulletproof insert plate after forming is easy to stick to the mold, which will cause direct damage to the green body when it is demoulded

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

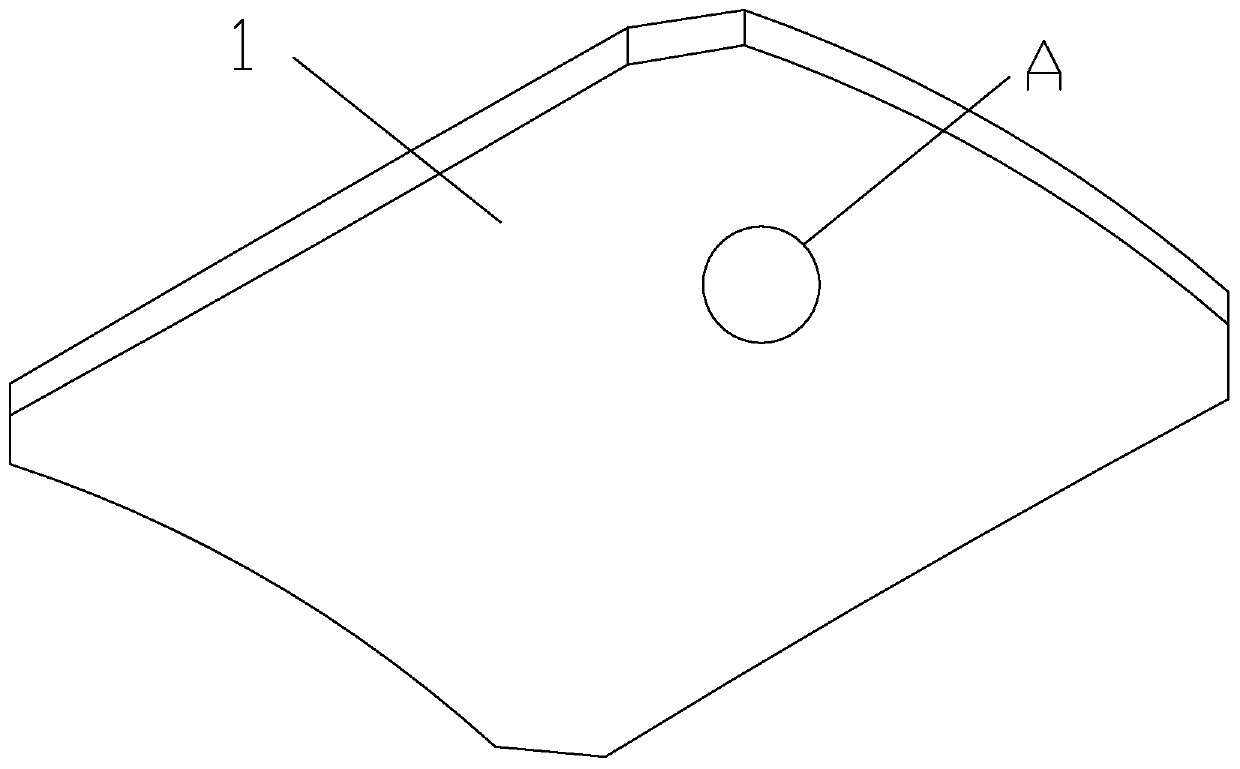

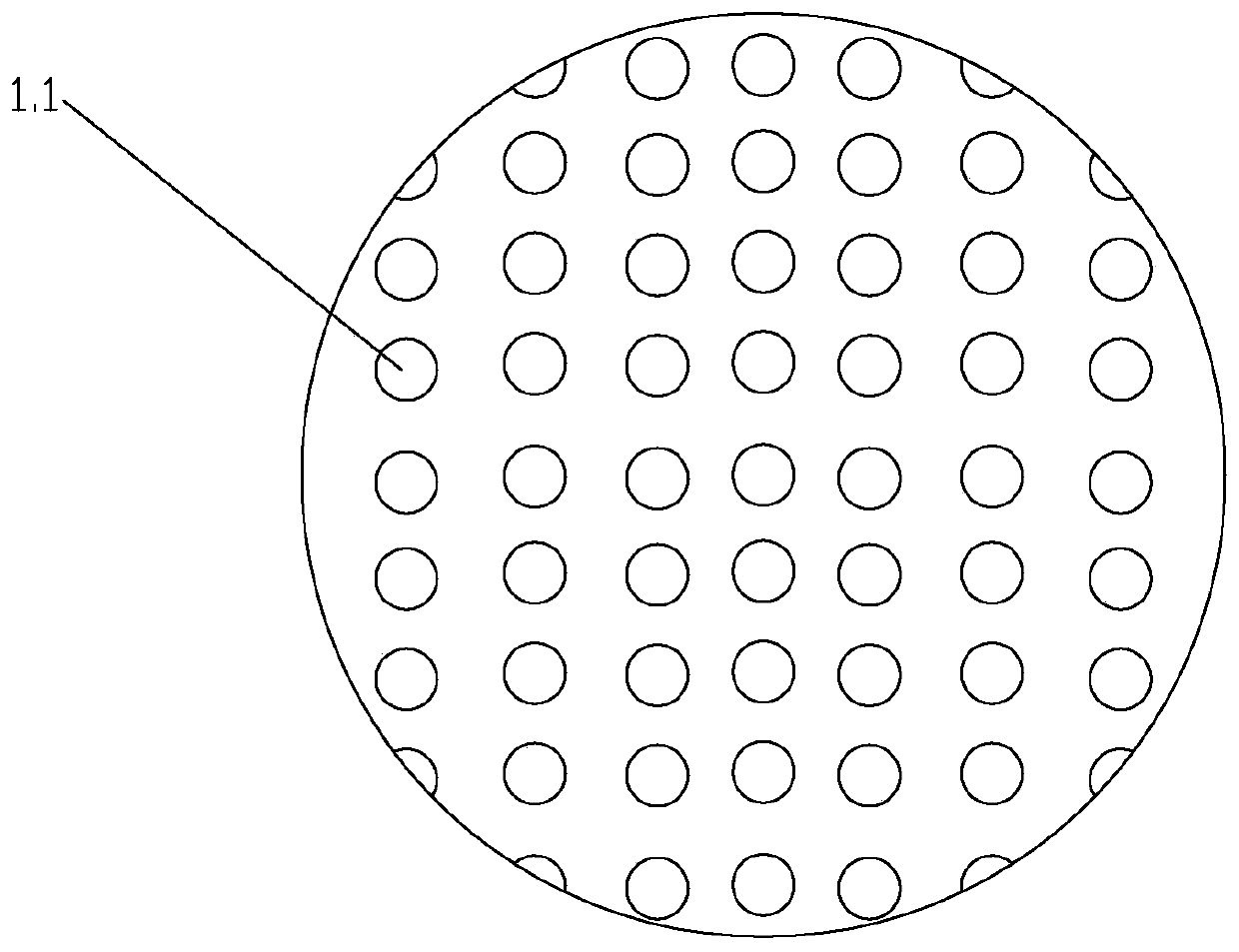

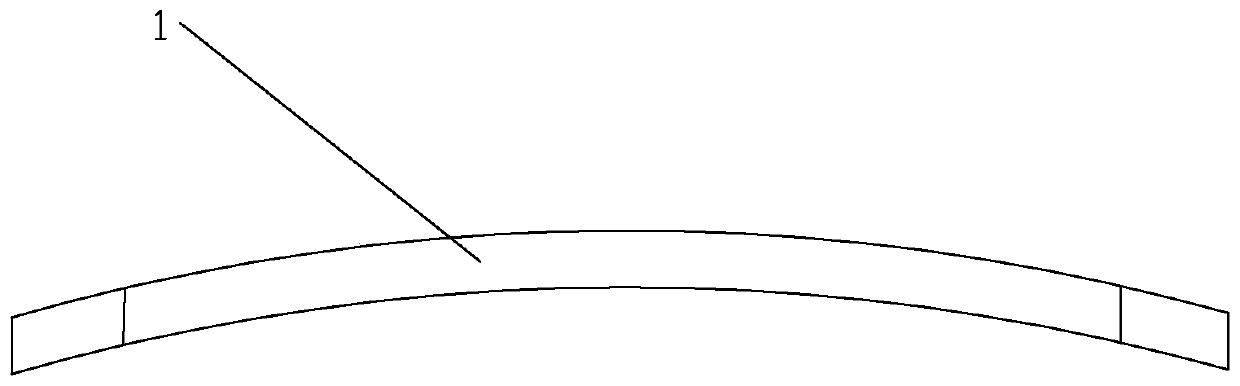

The invention discloses a manufacturing method for a bulletproof ceramic plug board. The front face of a water-permeable fiber cloth is attached to the convex face of a forming mould, and a ceramic green body is formed in the forming mould through a glue-injection forming method; a plurality of convex points are distributed on the concave face of the ceramic green body; a ceramic dry body is obtained after drying; and finally, the ceramic plug board is formed through sintering. According to the manufacturing method for the bulletproof ceramic plug board, the evenly-distributed convex points are formed on the bulletproof ceramic surface in a prefabricated mode, and accordingly the large gluing area is achieved when the bulletproof ceramic plug board and a polyethylene plate are bonded and composited; and meanwhile, the convex points can restrain sliding between ceramic pieces and the polyethylene plate, the pasting effect is improved, stripping of the ceramic pieces is reduced, and thesafety of the bulletproof plug board is improved.

Description

technical field The invention belongs to the technical field of ceramic molding, and relates to a method for molding and preparing a bulletproof ceramic insert. Background technique At present, the bulletproof layer of the bulletproof board is usually combined with a polyethylene board and a ceramic board, and the ceramic board is bonded to the outside of the polyethylene board by glue, and it is pressed tightly so that it can be firmly bonded. This composite board not only has better Bulletproof effect, and better wearing comfort. Generally, the surface of bullet-proof ceramics that are compounded is relatively smooth. In the process of bonding bullet-proof ceramics and polyethylene boards with glue, negative pressure is required to ensure the bonding strength of ceramic boards and polyethylene boards to prevent falling off. At this stage, the bulletproof ceramics in the bulletproof board mainly have two methods of splicing small pieces of ceramics and the method of monol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28B1/30

Inventor 邬国平熊礼俊于明亮谢方民

Owner NINGBO VULCAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com