Forming roller of equipment for producing monowing labyrinth type drip tapes

A labyrinth, drip irrigation belt technology, applied in the direction of presses, presses, manufacturing tools, etc. using rotating pressure components, can solve the problems of increased material cost, high processing difficulty, imprints on the joints of flat parts, etc., to improve production. Efficiency, reduced rotational inertia, increased stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with the examples, the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

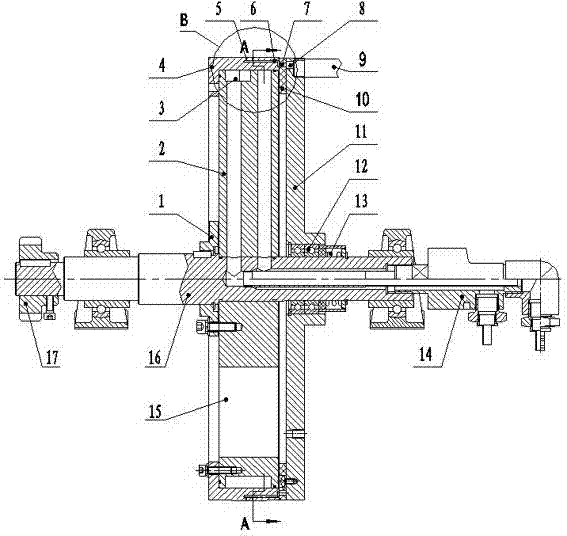

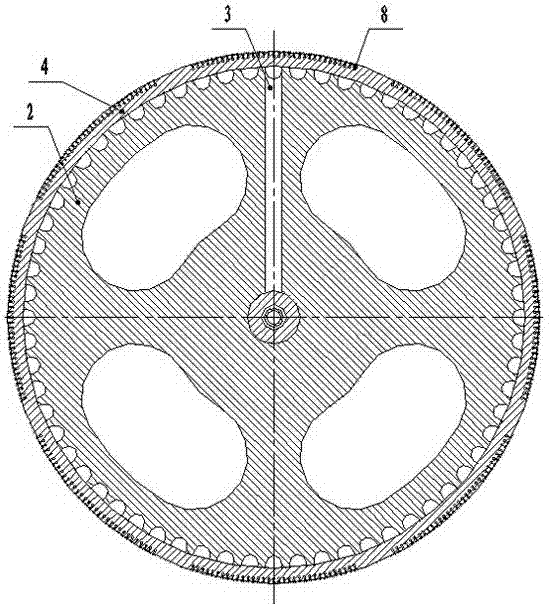

[0018] Referring to the accompanying drawings, this forming wheel for producing single-wing labyrinth drip irrigation belt equipment consists of a main shaft flange 1, a cooling body 2, a forming body 4, a friction plate 10, a compression flange 11, a pressure spring 13, a rotating shaft 16, etc. composition.

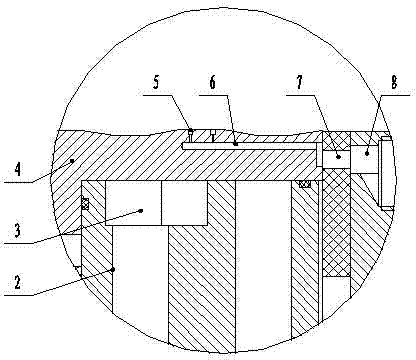

[0019] The molded body 4 is set on the outer circumference of the cooling body 2, and the outer circumference of the molded body 4 is processed with several sections of labyrinth runner patterns 5 that are symmetrical, continuous, regular, and concave. Each labyrinth channel pattern 5 on the circumferential surface is connected to each independent vacuum air channel 6, and the outer end of the forming body 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com