A high-reflectivity powder coating spraying equipment for lamp production

A high-reflectivity, powder coating technology, used in coatings, devices that apply liquid to surfaces, etc., can solve problems such as uneven coating, low work efficiency, time-consuming and laborious, and achieve improved work efficiency and accurate rotation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

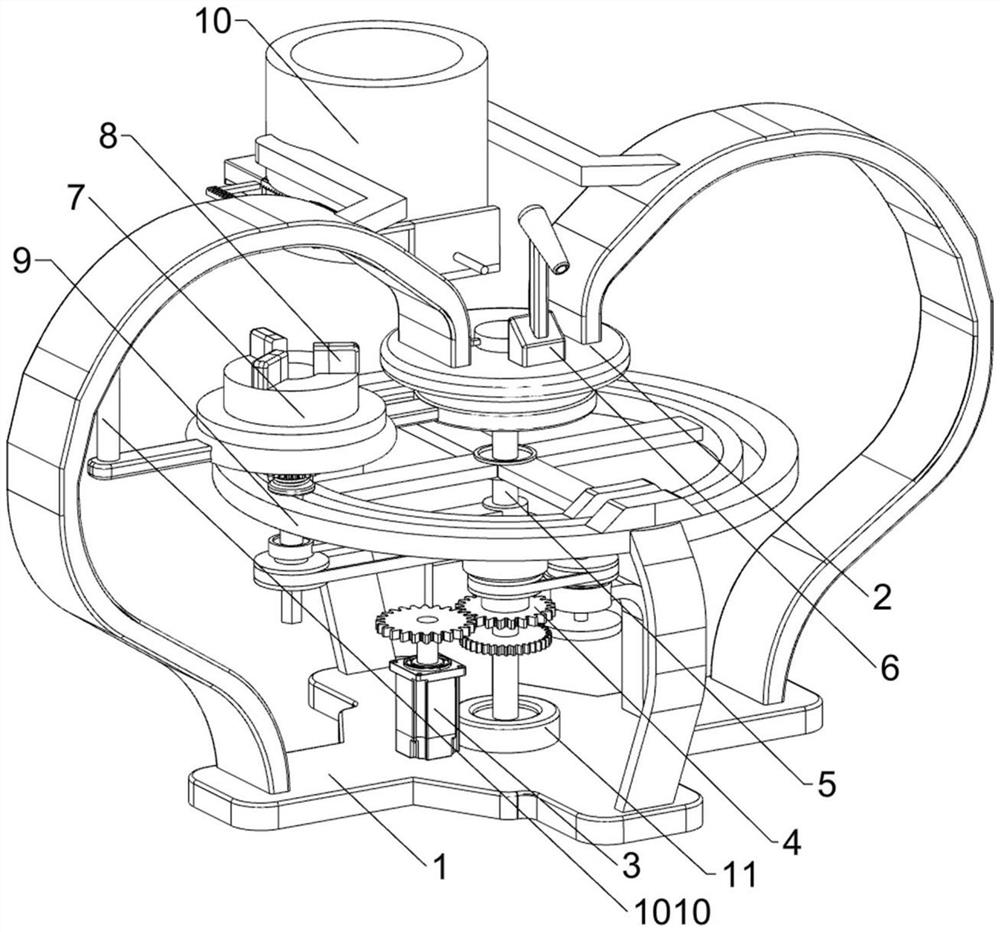

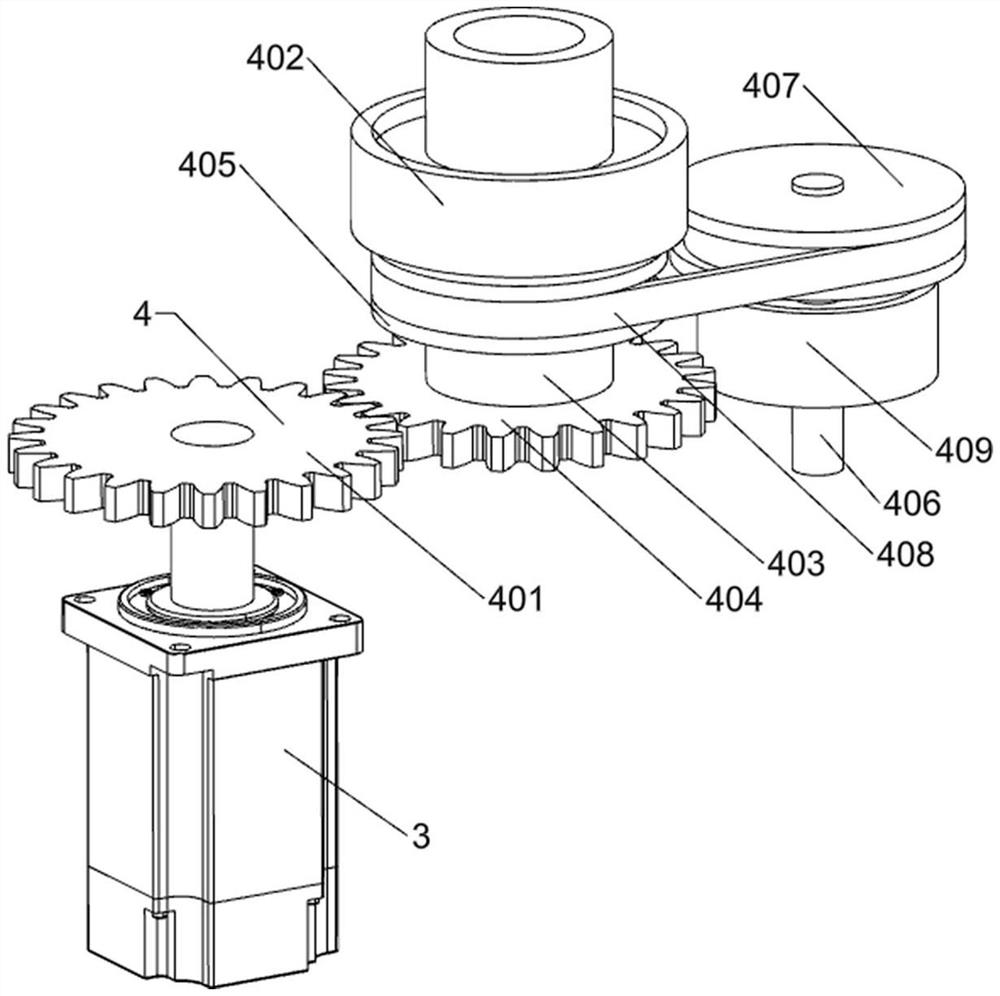

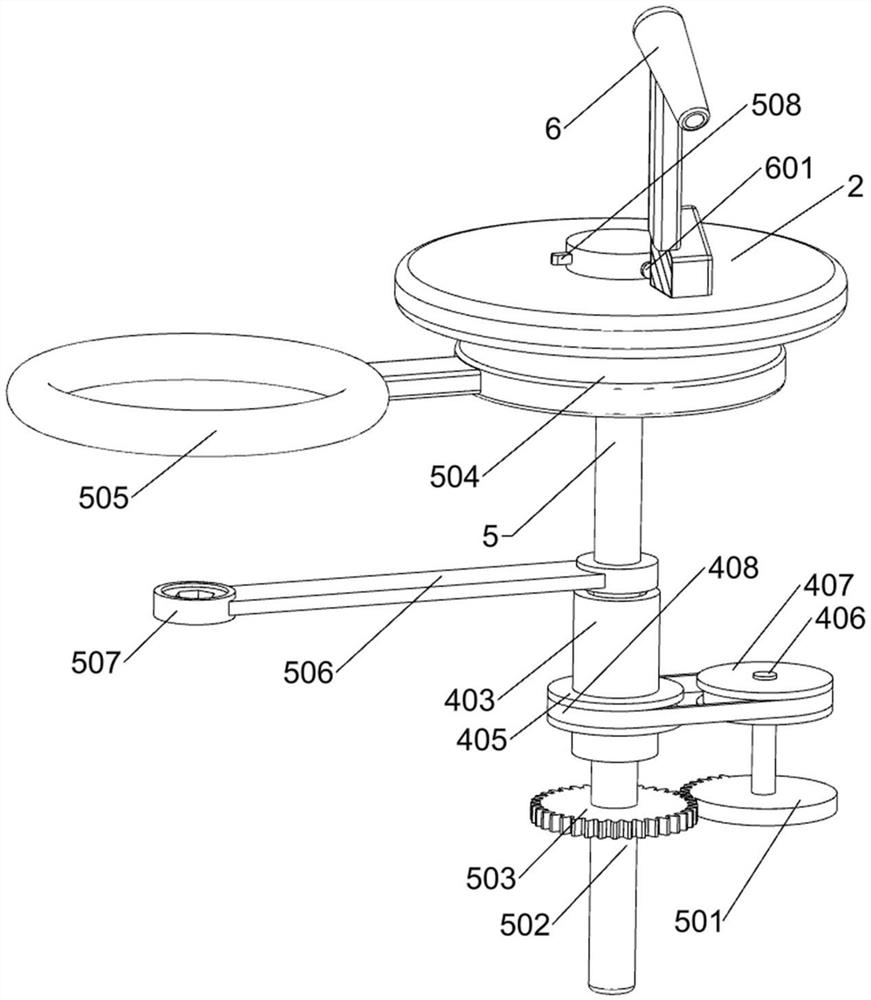

[0029] A high-reflectivity powder coating spraying equipment for lamp production, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a base 1, a first support plate 2, a motor 3, a transmission assembly 4, an intermittent rotation assembly 5, a nozzle 6, a touch switch 601 and a shelf 7. The upper middle of the base 1 is provided with a first support plate 2, and the base 1. A motor 3 is provided on the left side of the upper middle part. A transmission assembly 4 is provided on the rear side of the upper middle part of the base 1. An intermittent rotation assembly 5 is provided between the first support plate 2 and the base 1. A nozzle is provided on the front side of the top of the first support plate 2. 6. A touch switch 601 is provided on the rear side of the lower part of the sprinkler head 6, and the touch switch 601 controls the sprinkler head 6, and the left side of the intermittent rotation assembly 5 is provided with a shelf 7.

[0030]The...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a clamping assembly 8 is also included, and the clamping assembly 8 includes a second contact rod 801, a second support plate 802, a first spring 803, a first slider 804, a second slider 805 and a third contact rod 806, three first sliders 804 are provided with evenly spaced sliding inside the middle part of the storage rack 7, and the inner lower part of the first slider 804 is provided with a second contact rod 801, and the outer side of the upper part of the first slider 804 is provided with a second slider 805, three second support plates 802 are arranged on the inner side of the lower part of the storage rack 7 evenly spaced slidingly, and the first spring 803 is connected between the second support plate 802 and the first slider 804, and the third bearing 507 is provided with a rotating type. The third contact rod 806 , the third contact rod 806 can slide up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com