Drive method for mechanical drive device and mechanical drive device

A technology of mechanical drive and drive method, which is applied in transmission control, mechanical equipment, components with teeth, etc., can solve problems such as inconvenience for users, single drive device, and inability to change the working mode of the distributor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

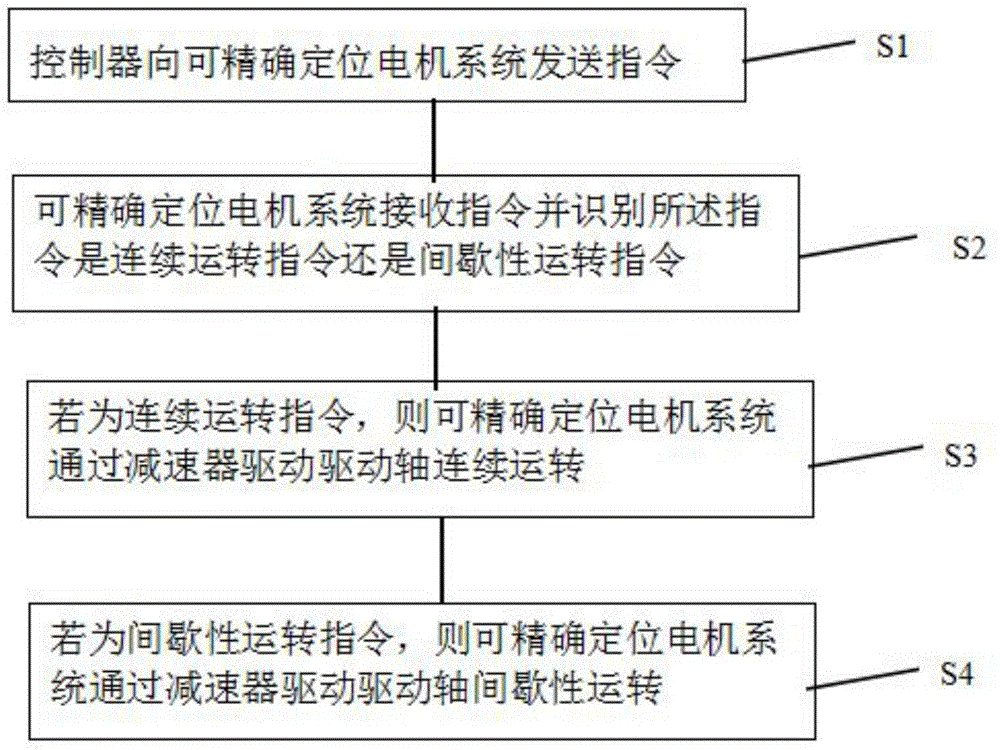

[0042] Embodiment one, such as figure 1 As shown, a driving method for a mechanical driving device, the method includes the following steps,

[0043] Step S1: the controller 11 sends an instruction to the precise positioning motor system 1,

[0044] Firstly, the controller 11 sends instructions to the motor system 1 capable of precise positioning. The motor system 1 capable of precise positioning may adopt servo motors or other motors capable of precise positioning. The motor system 1 capable of precise positioning includes a signal input terminal and a power output terminal. The power input end of the precise positioning motor system 1 is connected to the controller 11, and the power output end of the precise positioning motor system 1 is connected to the reducer 2; Step S2: The precise positioning motor system 1 receives the instruction And identifying whether the instruction is a continuous operation instruction or an intermittent operation instruction, the instruction in ...

Embodiment 2

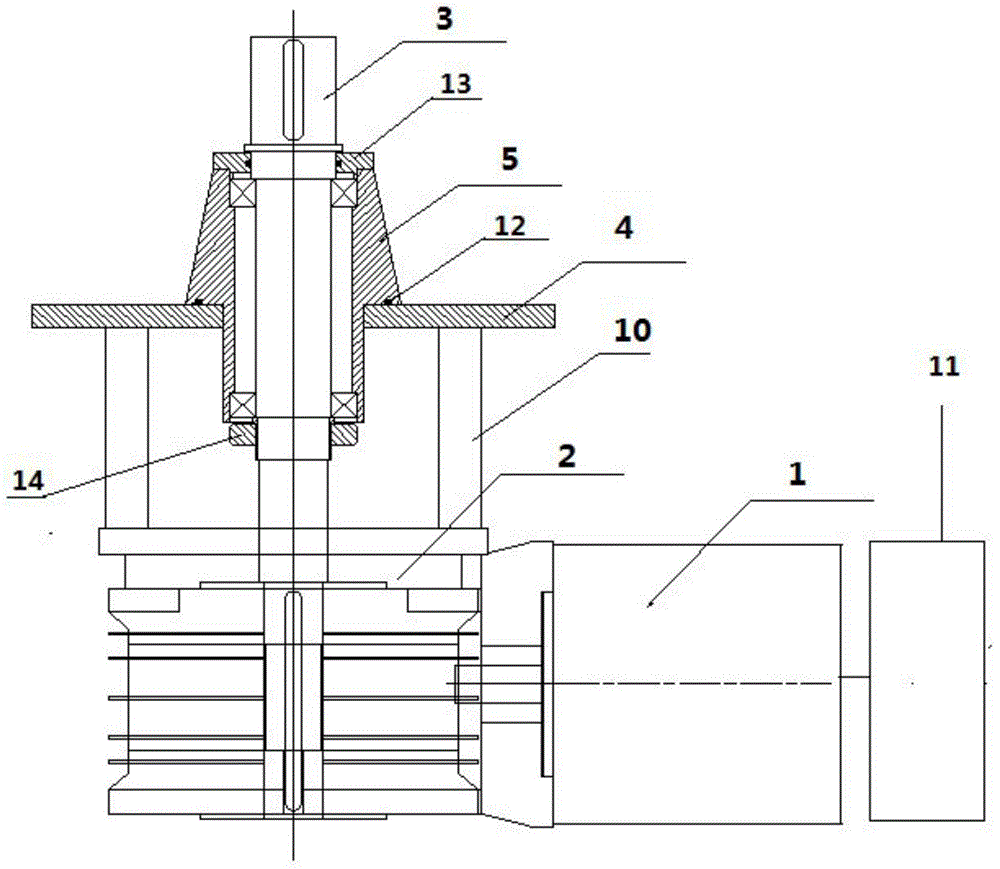

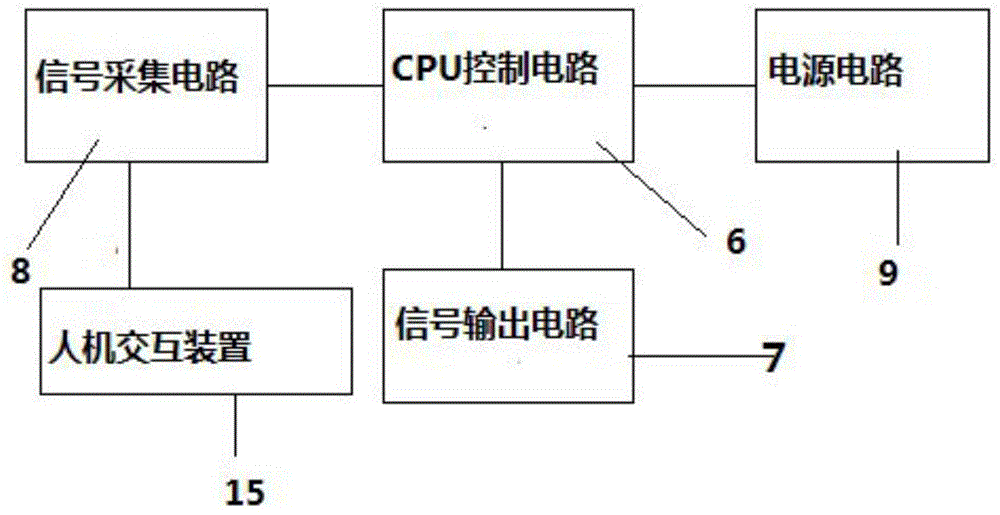

[0047] Embodiment two, such as figure 2 with image 3 As shown, a mechanical drive device includes a precisely positioned motor system 1, a reducer 2, a drive shaft 3 and a controller 11. The precisely positioned motor system 1 includes a signal input end and a power output end. The power output end of the positioning motor system 1 is connected to the reducer 2, the reducer 2 is connected to the drive shaft 3, and the controller 11 is connected to the signal input end of the precise positioning motor system 1, so The controller 11 sends an instruction to the precise positioning motor system 1, and the precise positioning motor system 1 receives the instruction and identifies whether the instruction is a continuous operation instruction or an intermittent operation instruction. If it is a continuous operation instruction, the precise positioning motor system 1 The drive shaft 3 is driven to run continuously through the reducer 2. If it is an intermittent operation command, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com