Inspection device and method for quickly eliminating size error and quickly clamping large lubricating oil tank

A technology for testing devices and dimensional errors, which is applied in the direction of mechanical counters/curvature measurement, etc., can solve problems such as dangerous operation, long installation time, and errors in the positions of the four mounting holes, and achieve stable and accurate movement accuracy, eliminate the influence of dimensional errors, The effect of quickly eliminating size errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

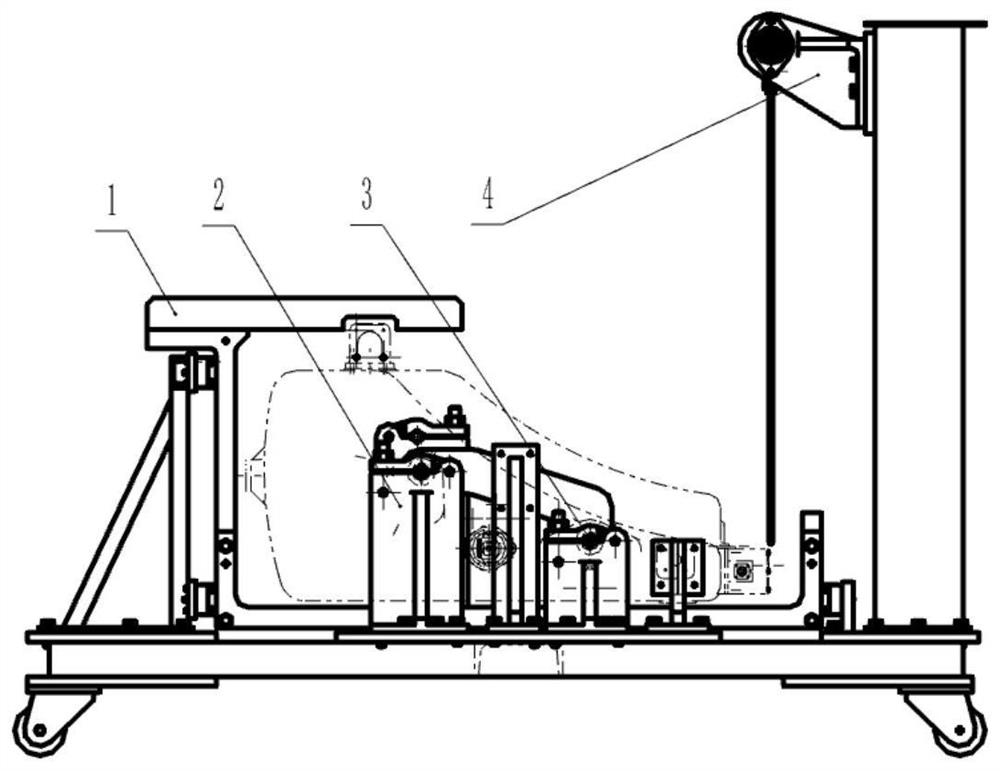

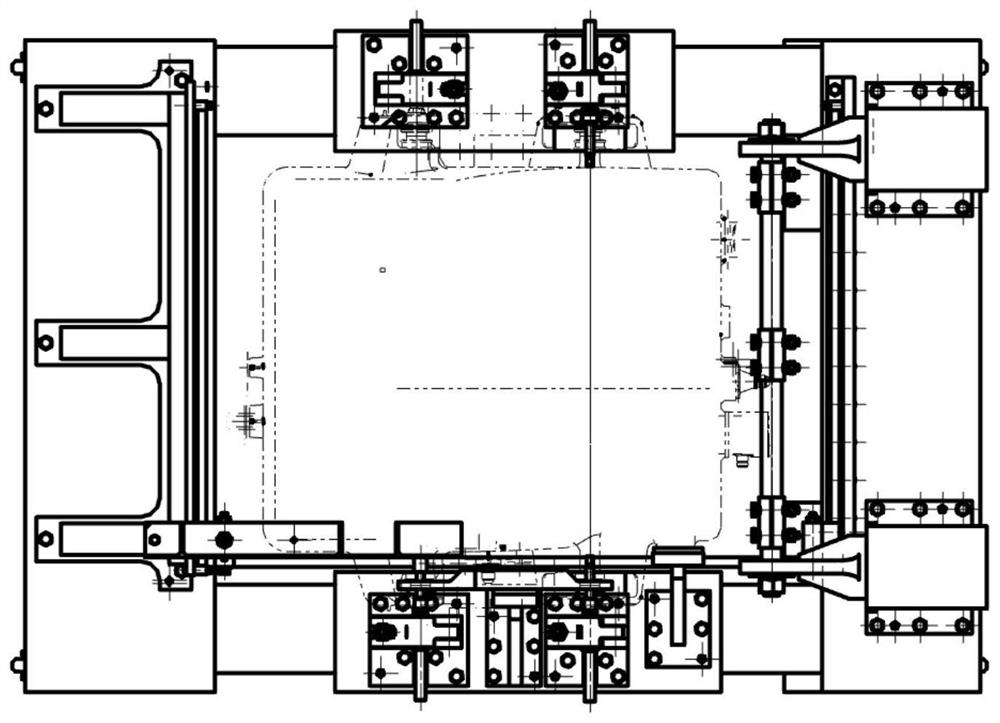

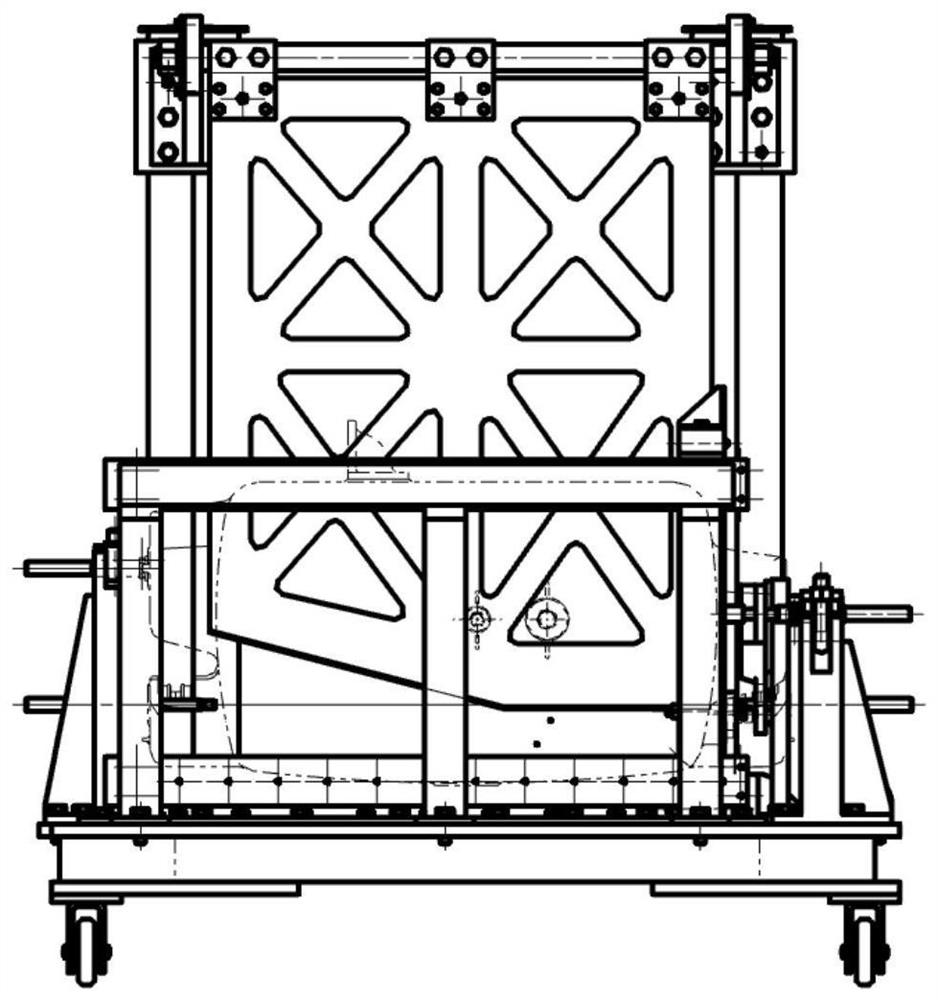

[0061] Such as Figure 12 As shown, since the installation hole of the large lubricating oil tank is located in the cast semi-surrounding structure 7, the product in the actual installation structure is fixed with four fixing seats 5, due to the size error of the installation hole, and the huge weight and volume of the product, four It is difficult to install and adjust the fixing seat 5 (the bottom bolt of the fixing seat 5 needs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com