a shaft

A rotating shaft and rotating shaft technology, which is applied in the electronic field, can solve the problems of many gaps between gears, many parts required, and high production costs, and achieve the effects of simple splicing, low processing difficulty, and improved production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

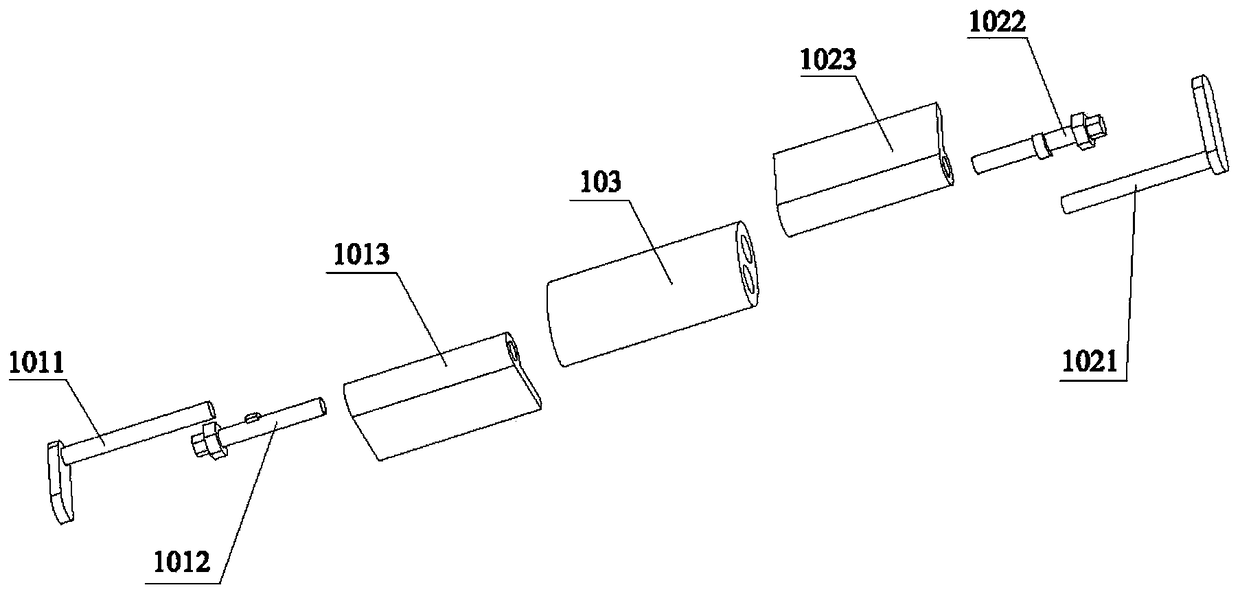

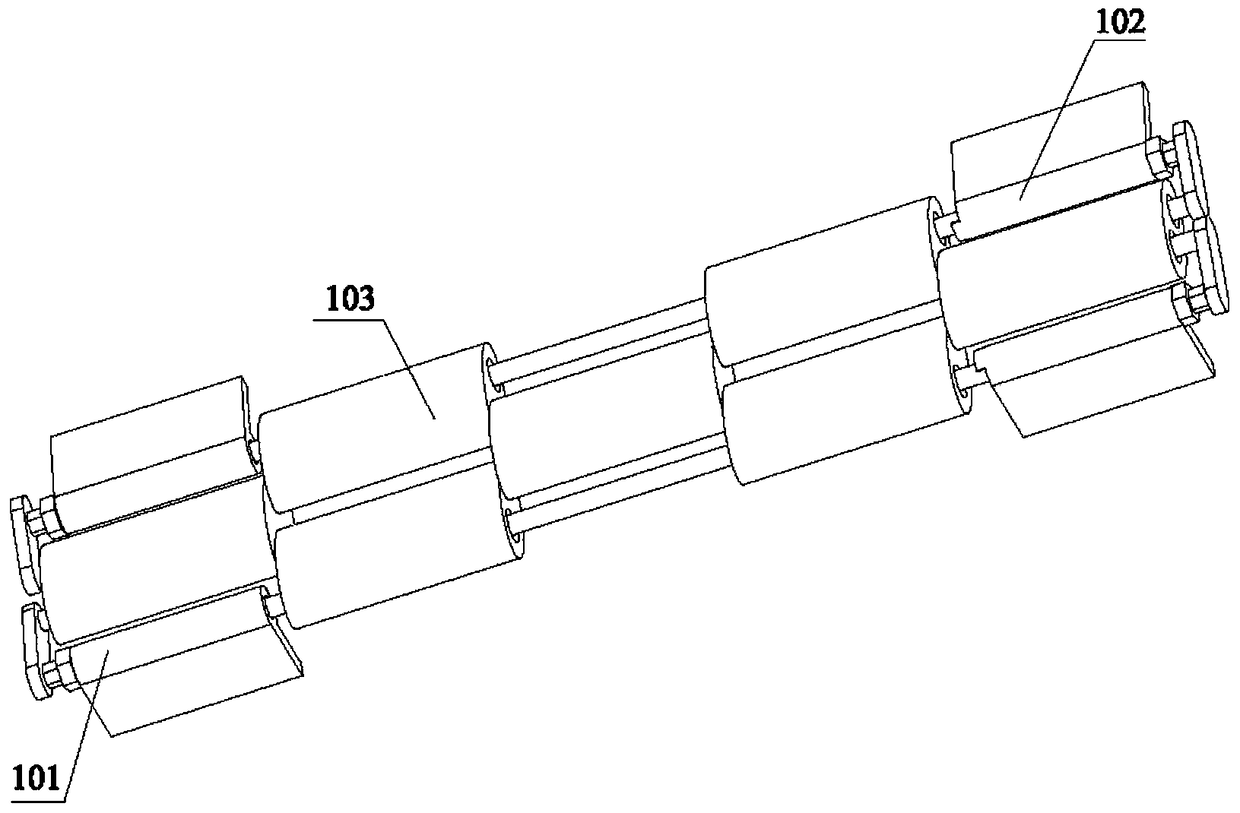

[0037] Please refer to figure 1 , figure 2 , Embodiment 1 of the present application provides a first rotating member 101, including a first connecting member 1011, a first rotating shaft 1012 and a first shaft sleeve 1013, the first connecting member is fixedly connected to the first rotating shaft, and the first The rotating shaft is sleeved in the first shaft sleeve, and the first shaft sleeve can rotate relative to the first rotating shaft, and the first shaft sleeve is connected to the first body of the first electronic system;

[0038] The second rotating member 102 includes a second connecting member 1021, a second rotating shaft 1022 and a second shaft sleeve 1023, the second connecting member is fixedly connected with the second rotating shaft, and the second rotating shaft is sleeved on the first rotating shaft. In the second shaft sleeve, and the second shaft sleeve can rotate relative to the second rotating shaft, the second shaft sleeve is connected to the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com