A kind of high-strength recycled concrete and preparation method thereof

A recycled concrete, high-strength technology, applied in the field of concrete production, can solve problems such as cracks, limit the use range of recycled concrete, and low mechanical properties of recycled concrete, achieve the effect of reducing the number of gaps, improving synergistic effects, and increasing the use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

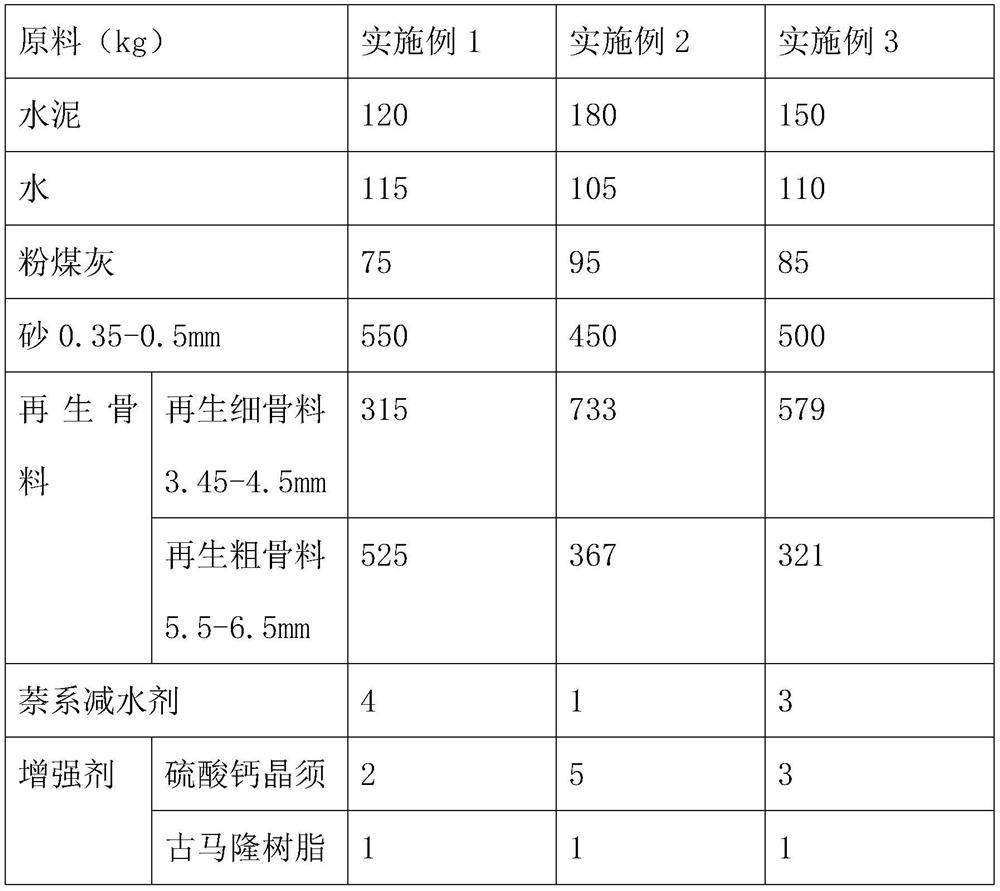

Embodiment 1-3

[0051] A high-strength recycled concrete is prepared by the following steps:

[0052] Step 1: The calcium sulfate whisker and coumarone resin are stirred for 15min under the condition of rotating speed of 220r / min in proportion, and the reinforcing agent is obtained after mixing evenly;

[0053]Step 2: Mix the reinforcing agent, the naphthalene-based water reducing agent, the cement, the regenerated coarse aggregate and the regenerated fine aggregate in proportion for 1.5 hours under the condition of a rotating speed of 90 r / min, and after mixing uniformly, a mixture A is obtained;

[0054] Step 3: Mix mixture A, water, sand and fly ash in proportion for 0.5h under the condition of rotating speed of 130r / min, and obtain high-strength recycled concrete after mixing evenly.

Embodiment 4

[0056] The difference from Example 3 is that the weight ratio of the naphthalene-based water-reducing agent to the reinforcing agent in Example 4 is 1:4, wherein the addition of the naphthalene-based water-reducing agent is 1kg, and the addition of the reinforcing agent is 4kg.

Embodiment 5

[0058] The difference from Example 3 is that the weight ratio of the naphthalene-based water-reducing agent to the reinforcing agent in Example 5 is 1:6, wherein the addition of the naphthalene-based water-reducing agent is 1kg, and the addition of the reinforcing agent is 6kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com