Plug welding hole welding device for stamping and welding shoe for automobile brake

A welding device and brake technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large noise, large space occupation, large volume, etc., and achieve the effect of eliminating relative position error and accurate rotation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

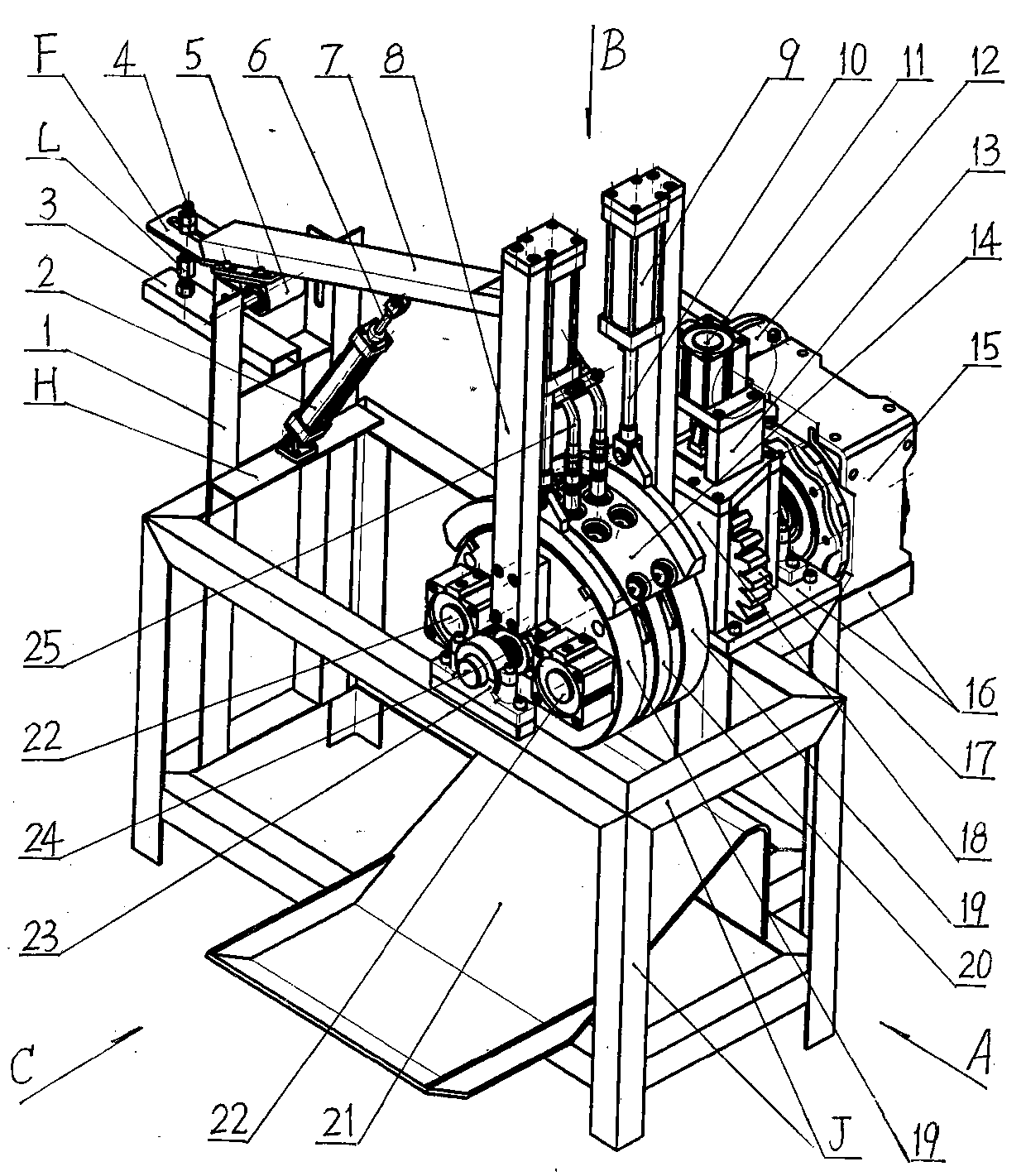

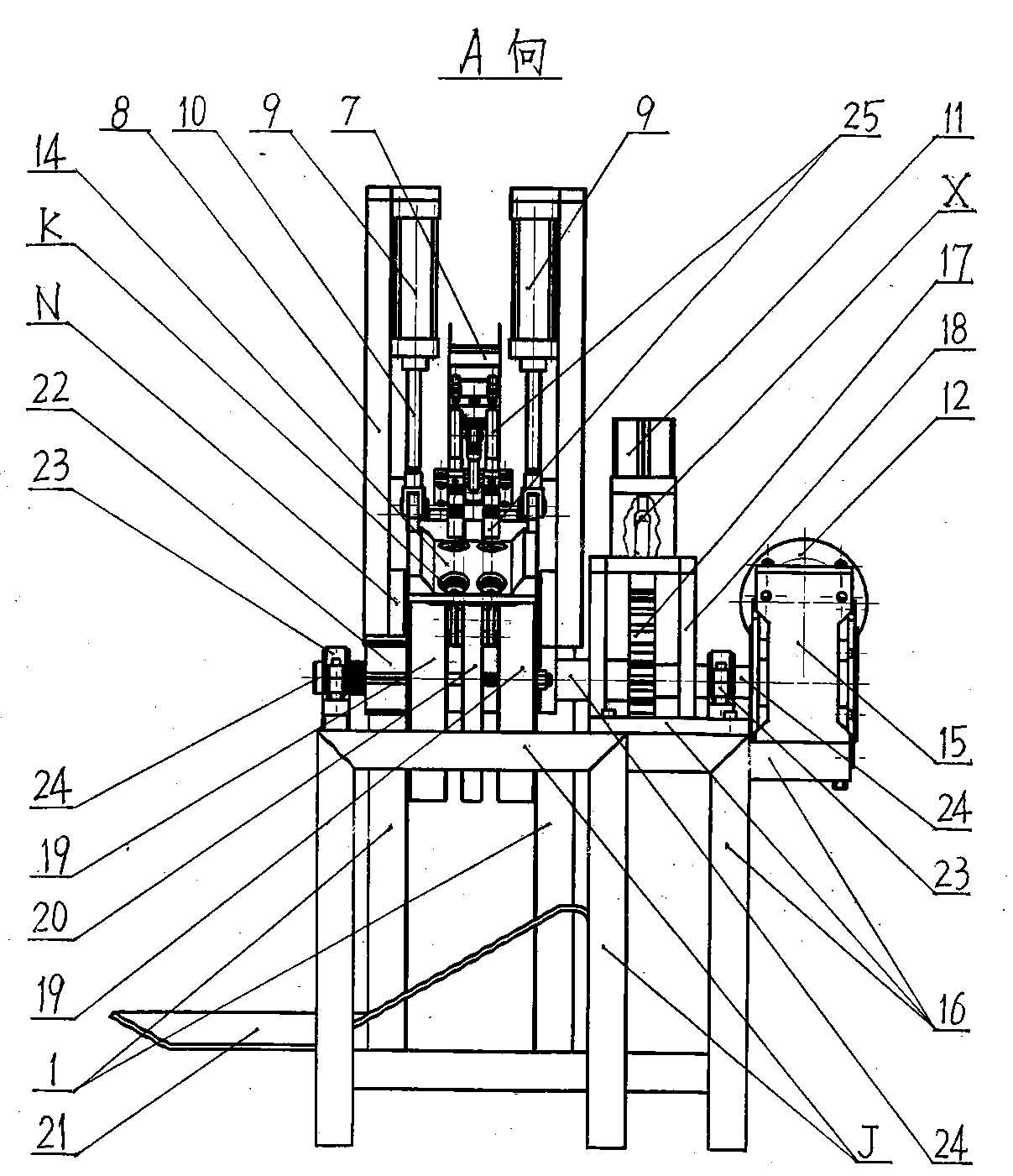

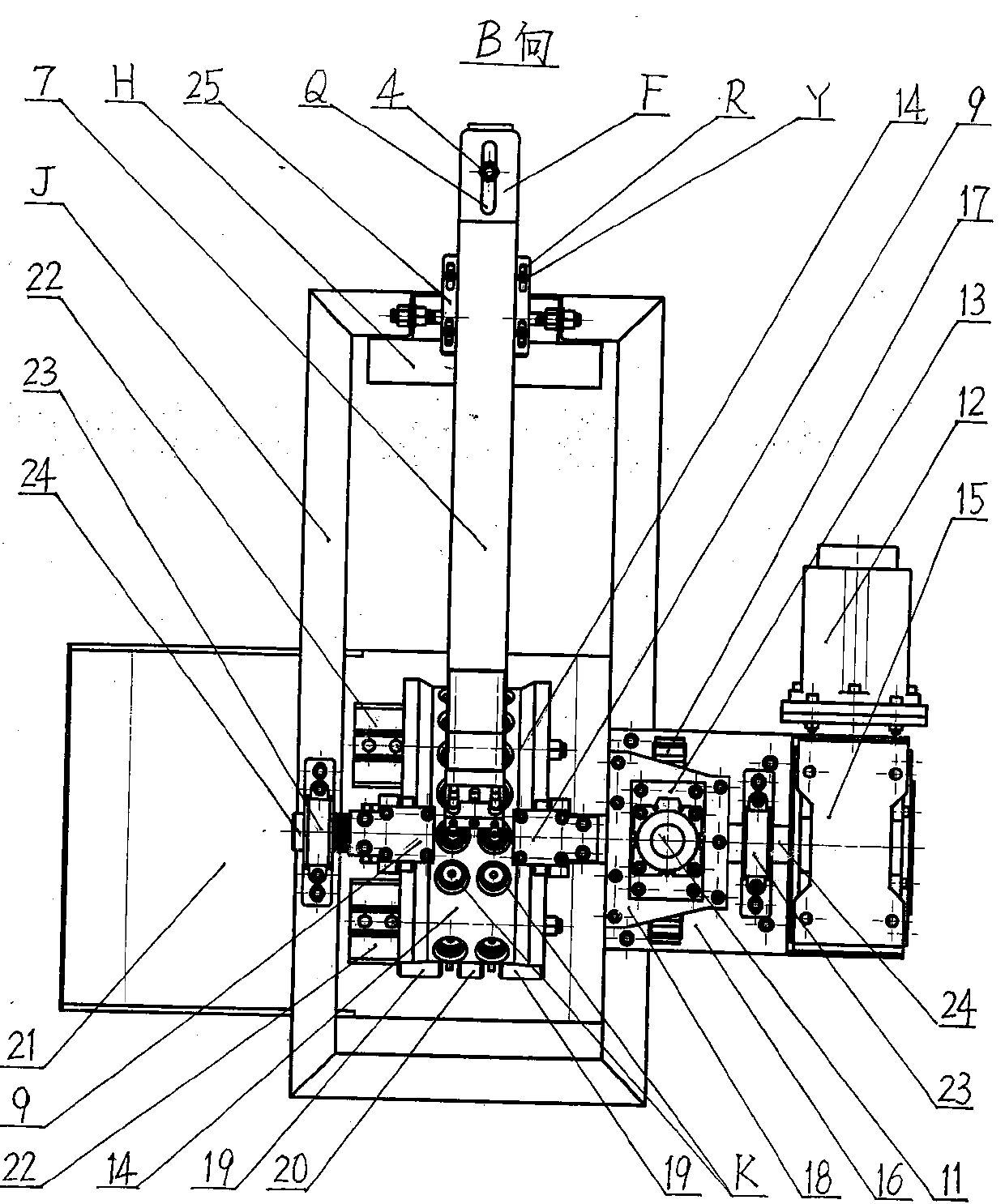

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention is composed of a clamping mechanism, a rotating mechanism, a guiding mechanism, and a welding torch mechanism installed on the frame J. The frame J is a rectangular connection frame made of angle steel welding, the rear part is connected to the welding torch frame support 1, and the right side is connected Reducer bracket 16; clamping mechanism includes gland 14, gland cylinder 9, gland cylinder frame 8, workpiece clamping wheel, clamping cylinder 22, and two gland cylinder frames 8 are erected on the left and right ends of the workpiece clamping wheel , the upper part of the gland cylinder frame 8 is equipped with the gland cylinder 9, the gland cylinder rod 10 is connected downward to the gland 14, the gland 14 is located on the workpiece cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com