Unmanned ship routing inspection device for offshore wind power plant and method thereof

A technology of unmanned ships and wind farms, which is applied to cleaning methods using liquids, special-purpose ships, and unmanned surface ships. The effect of amplitude swing, increased stability, and faster air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

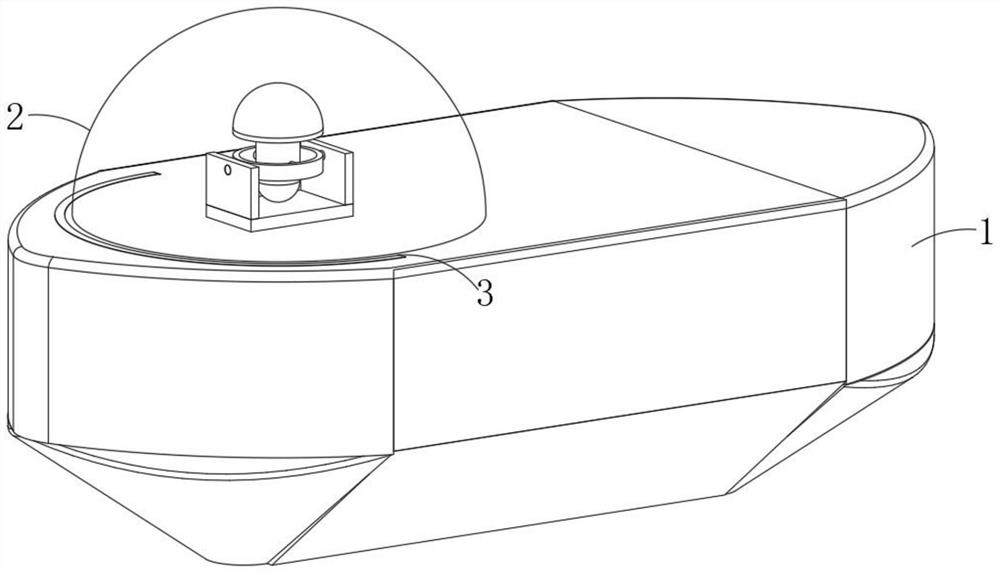

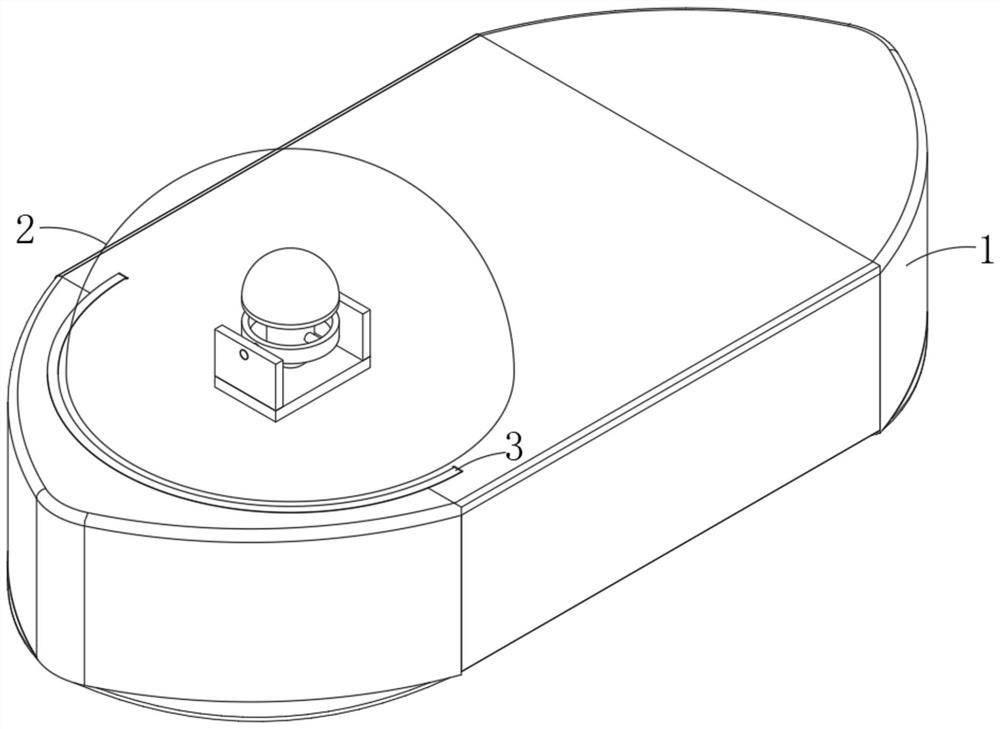

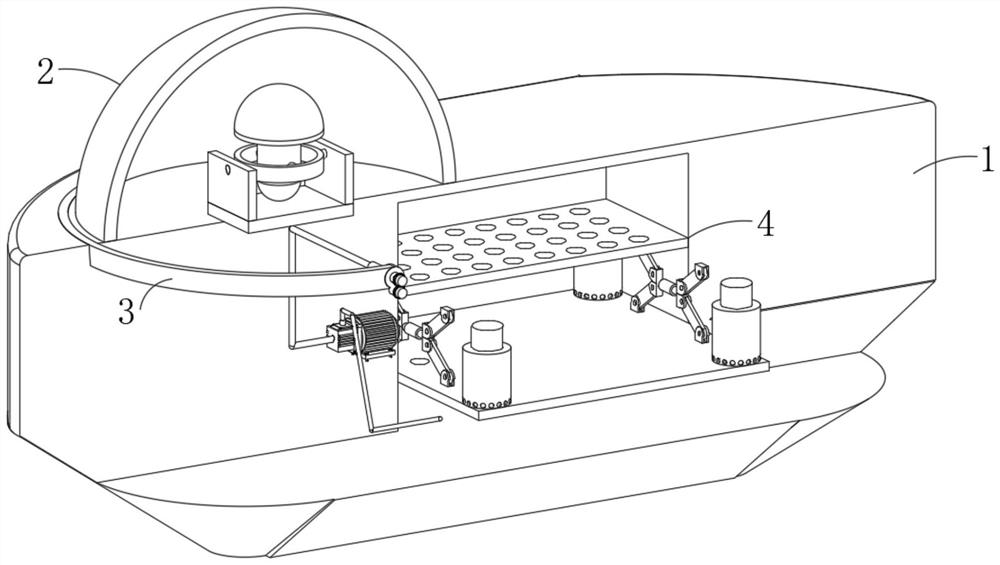

[0038] Embodiment one, with reference to Figure 1-9 : An unmanned ship inspection device and method for offshore wind farms, comprising: an unmanned ship body 1; the unmanned ship body 1 is set for inspection, a stabilizing mechanism 2, and the stabilizing mechanism 2 includes a transparent cover 201 , the camera 202 and the supporting part, the transparent cover 201 is fixedly connected to the top of the unmanned ship body 1, the supporting part is arranged in the transparent cover 201, and the supporting part is arranged on the top of the unmanned ship body 1, and the camera 202 is arranged on the supporting part The setting of the stabilizing mechanism 2 is used to reduce the damage of the internal components of the unmanned ship body 1, and the setting of the transparent cover 201 can facilitate the shooting and inspection of the camera 202. The structure and principle of the camera 202 belong to the prior art, and will not be described in detail here , its model can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com