Automatic intelligent cloth clamping equipment and working method thereof

A cloth clamping and equipment technology, applied in textiles and papermaking, embroidery machines, feeding devices, etc., can solve the problems of unsatisfactory uniformity and coordination, waste, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

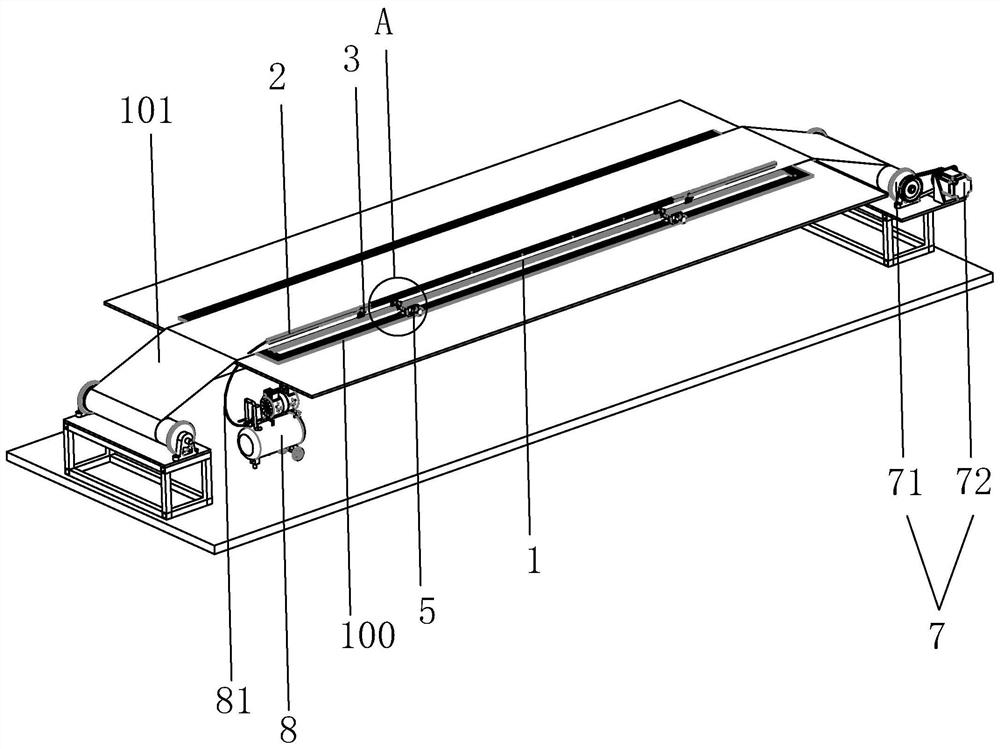

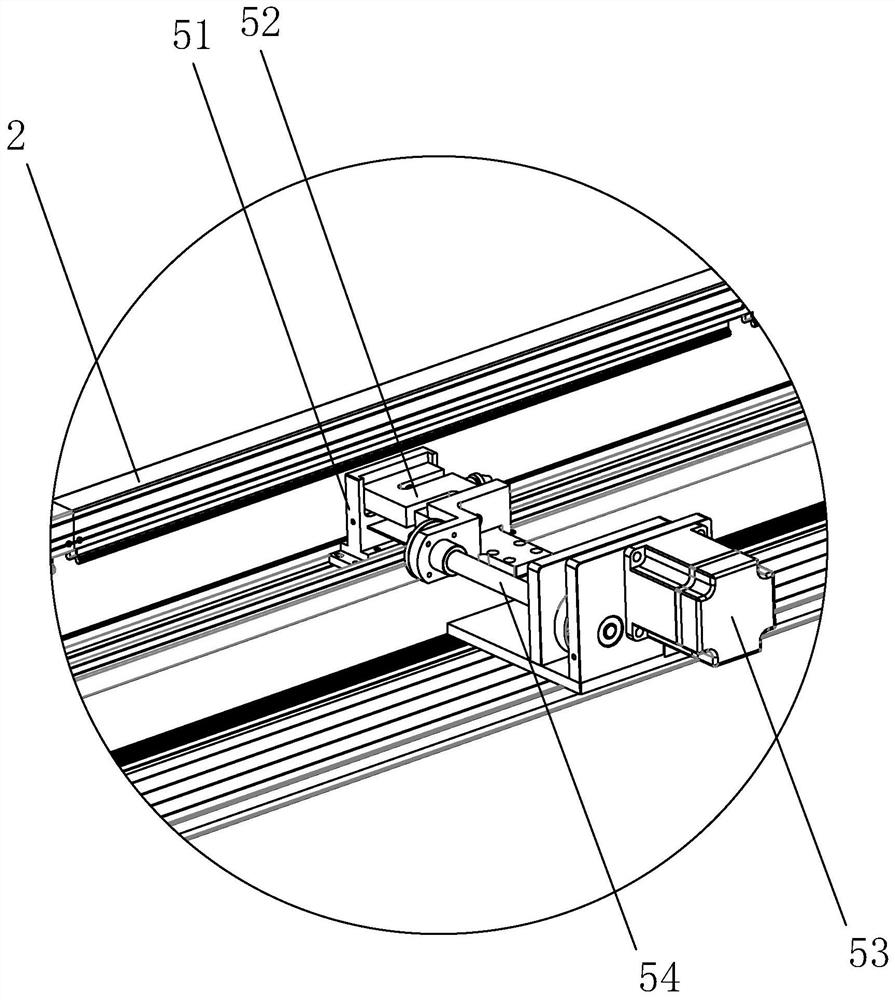

[0041] Such as figure 1 As shown, an automatic intelligent cloth clamping device includes an embroidery frame 100 and a cloth clamping base 1 arranged in the embroidery frame 100, and the cloth clamping base 1 is provided with a cloth clamping assembly 2; wherein, the embroidery frame 100 is provided with Adaptive tension adjustment mechanism 5, the adaptive tension adjustment mechanism 5 is connected to the back of the cloth clamping assembly 2, the adaptive tension adjustment mechanism 5 can control the cloth clamping base 1 to move along the width direction of the embroidery frame 100; wherein, the two sides of the embroidery frame 100 An embroidered cloth rolling mechanism 7 is provided, and the embroidered cloth rolling mechanism 7 can control the cloth 101 to move along the length direction of the embroidery frame 100 . Such as figure 2 As shown, the self-adaptive tension adjustment mechanism 5 includes a driving mechanism arranged on the embroidery frame 100 and a con...

Embodiment 2

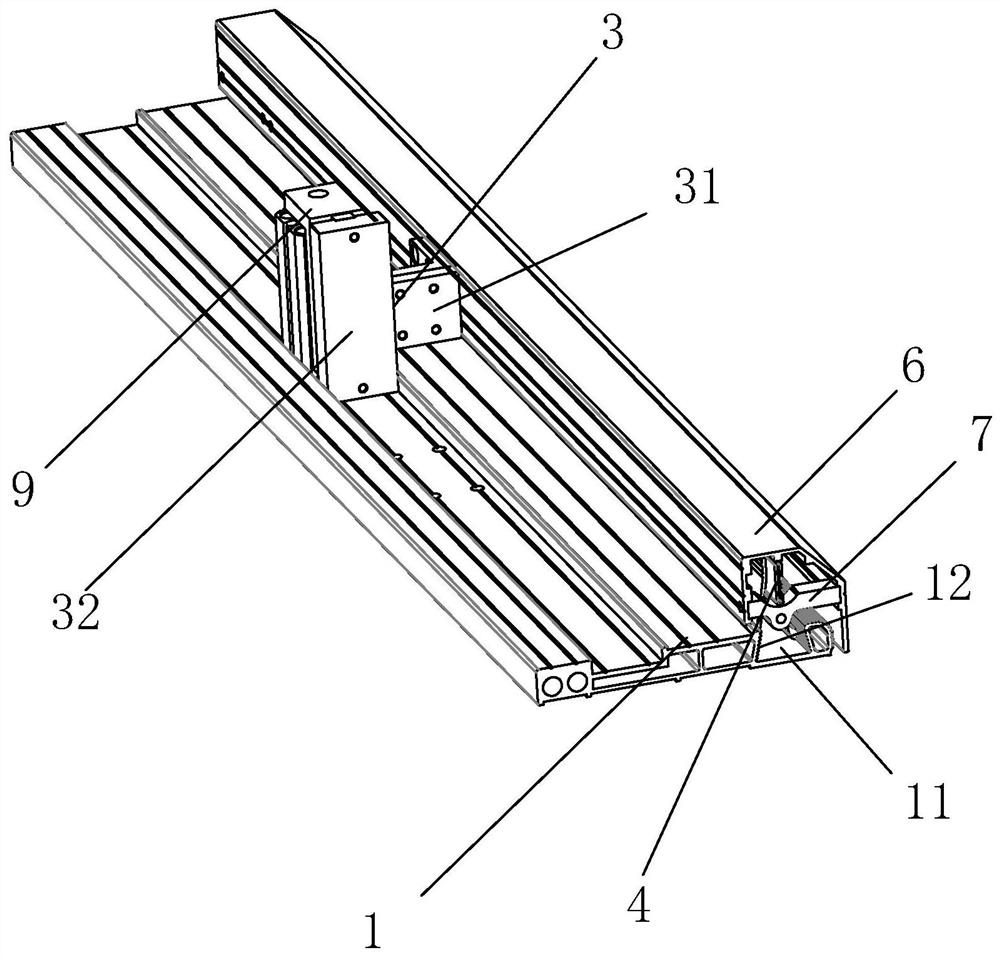

[0052] Different from Embodiment 1, in this embodiment, the driving mechanism of the self-adaptive tension adjustment mechanism 5 uses a horizontally arranged air cylinder or electric cylinder to drive the cloth clamping base 1 to move. This solution is more mature and the cost is lower. Such as Figure 5 As shown, the lifting assembly 3 that controls the cloth clamping assembly 2 is replaced by a hinged rotating assembly 9, which can control the outer cover frame 6 and the clamping assembly inside it to swing, so that the cloth clamping assembly 2 can approach or move away from the cloth clamping base. Seat 1. In addition, the inner support member 42 is replaced by a telescopic rod mechanism, which can push open the upper ends of the hinge points of the two clamping arms 41 , so as to realize the normal operation of the cloth clamping assembly 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com