Grease-saving steel wire rope with anti-throwing property

A steel wire rope and anti-swing technology, which is applied in the field of steel wire rope equipment, can solve the problems of reducing grease, wasting grease, and reducing the service life of steel wire ropes, so as to achieve the effect of reducing the amount of throwing out and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

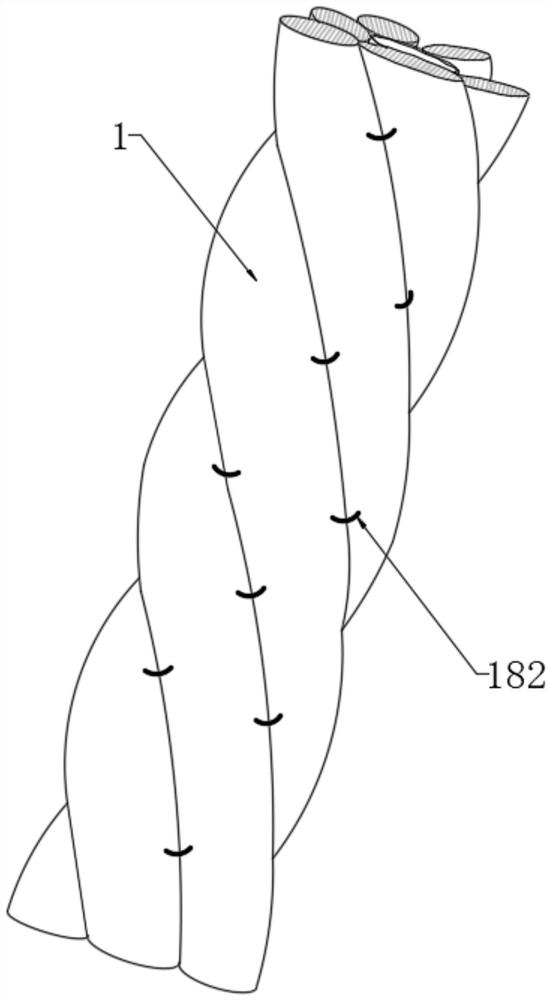

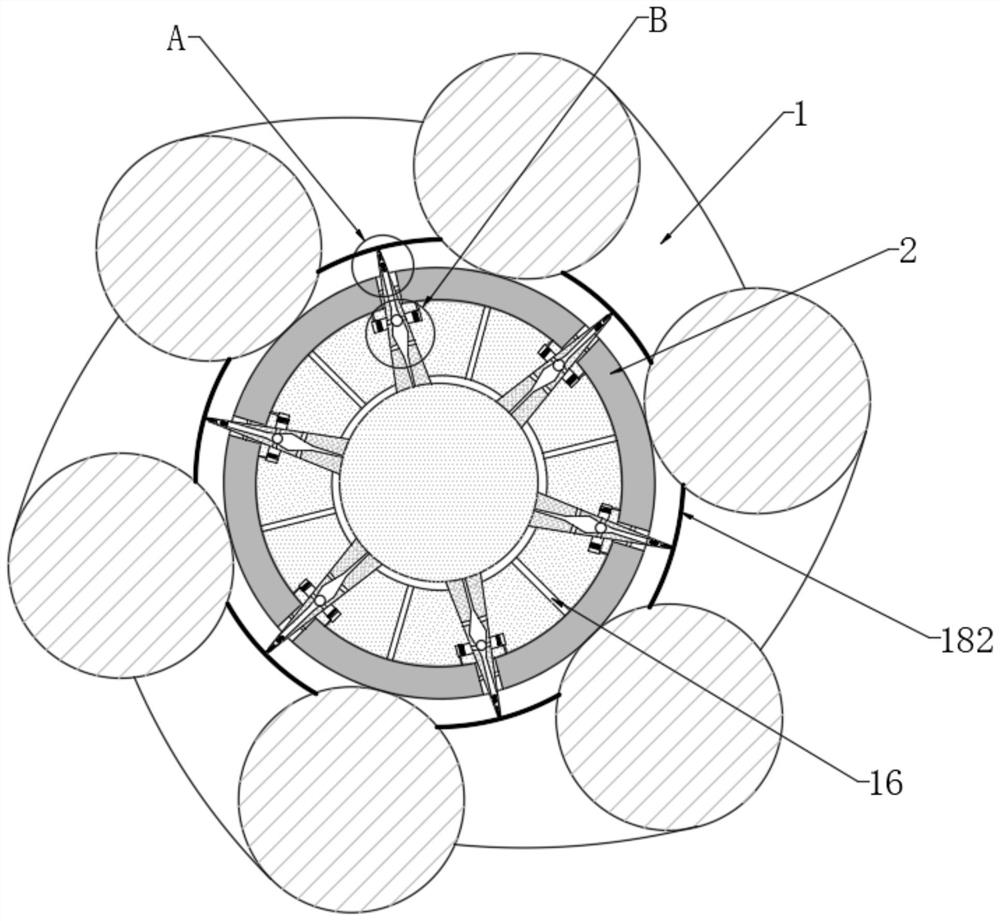

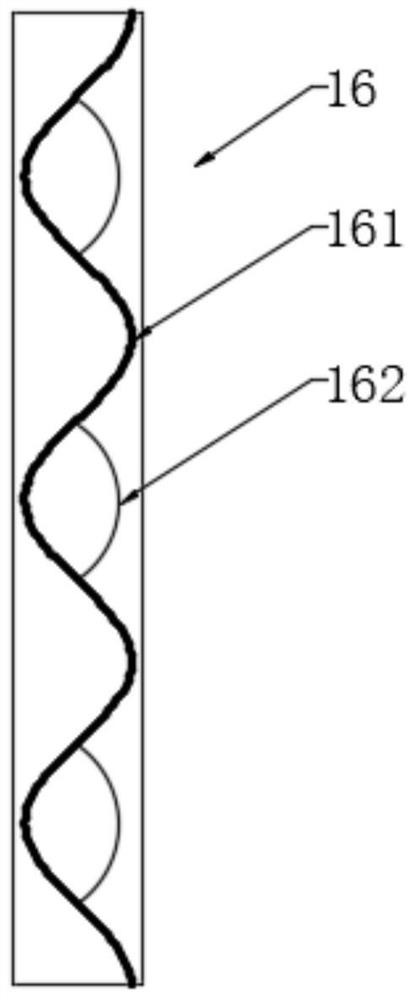

[0047] see Figure 1-8 , a fat-saving steel wire rope with anti-shake performance, comprising a plurality of steel wires 1 intertwined with each other, the plurality of steel wires 1 are fixedly connected with a flexible fat control tube 2 inside, and the flexible fat control tube 2 is fixedly connected with a plurality of segmental diaphragms inside 3. A fat storage cylinder 4 is fixedly connected between the multiple segmental diaphragms 3, and a plurality of evenly distributed elastic partitions 16 are fixedly connected between the steel wire 1 and the fat storage cylinder 4. The two elastic partitions 16 are connected with the fat storage There are lubricating grease 17 inside the cylinder 4, and a plurality of evenly distributed grease-discharging cones 5 are fixedly connected to the side wall of the grease-storing cylinder 4. A transport chamber 6 is excavated inside the grease-discharging cone 5, and an anti-corrosion valve is installed at the port of the transport chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com