Drainage pipeline inspection well construction quality detection equipment and use method thereof

A technology for construction quality and testing equipment, applied in mechanical equipment, waterway systems, water conservancy projects, etc., can solve problems such as inconvenient testing and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The application will be described in further detail below in conjunction with the accompanying drawings.

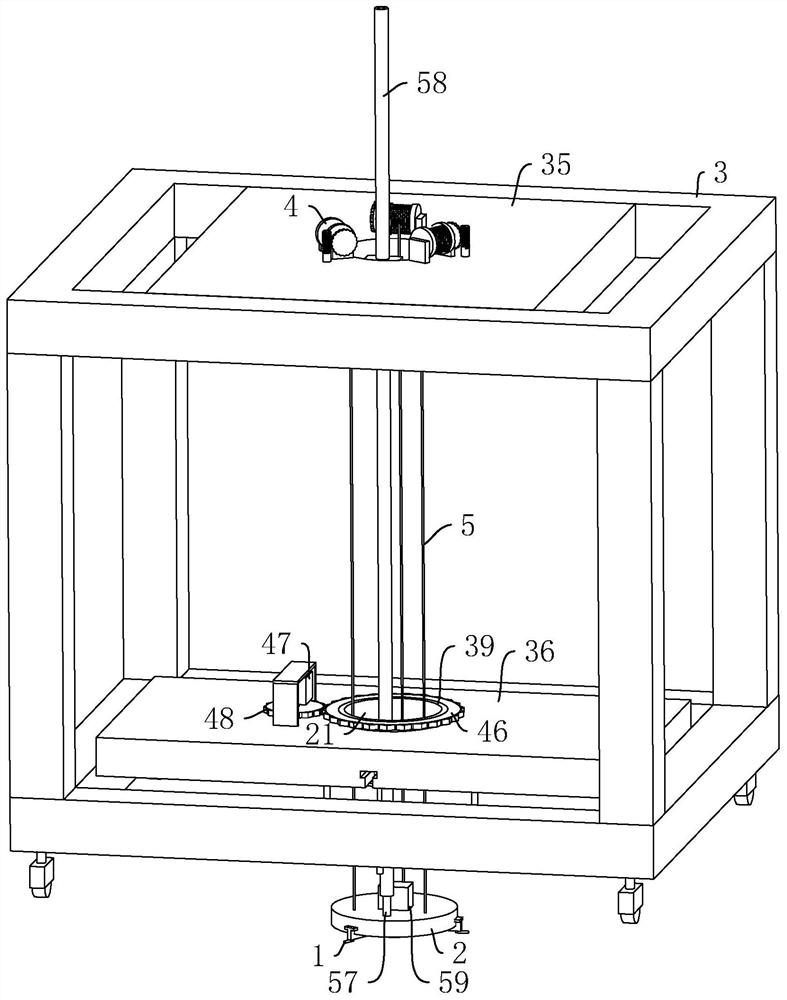

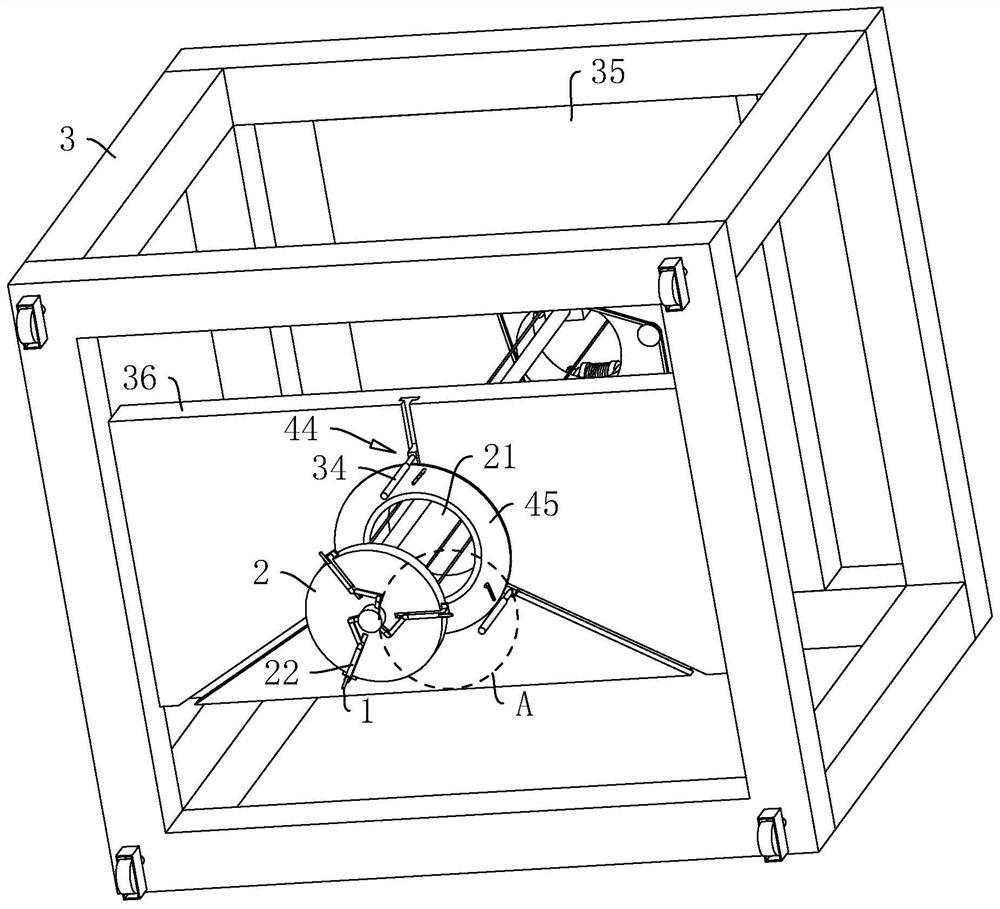

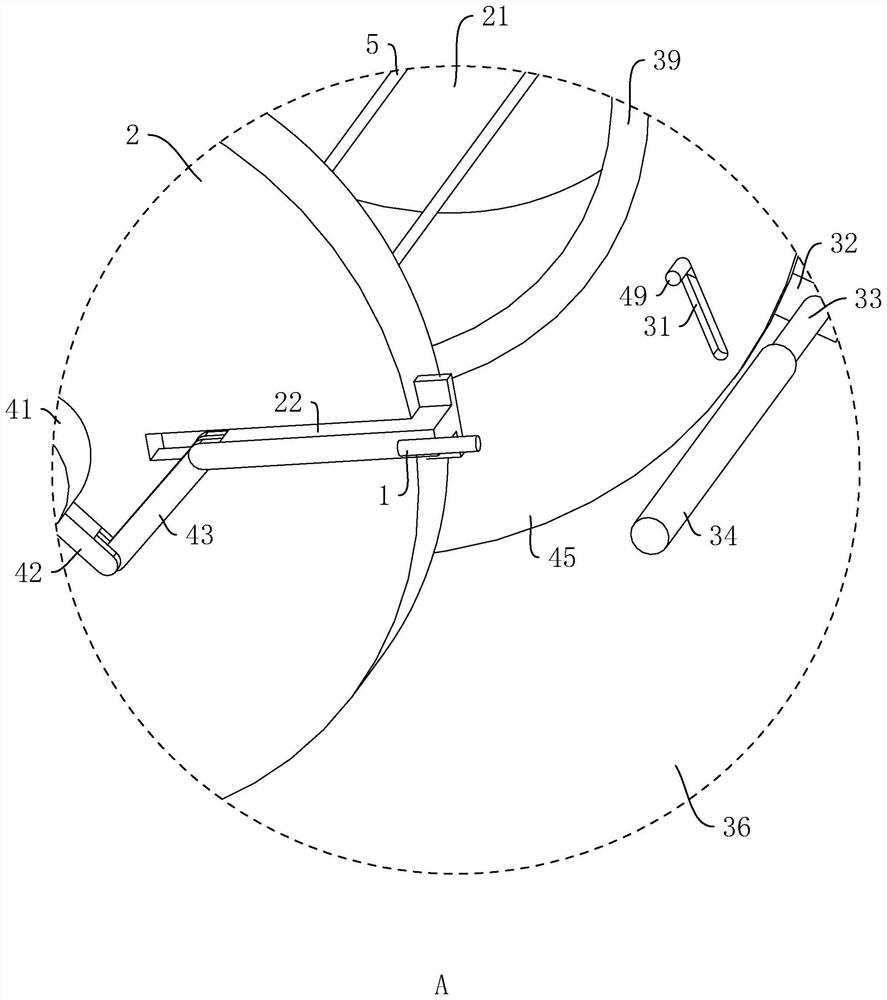

[0042] The embodiment of the present application discloses a construction quality inspection equipment for inspection wells of drainage pipes.figure 1 , including a mobile frame 3 located above the well cover seat, a universal wheel is rotated at the four corners of the bottom of the mobile frame 3, the universal wheel is in rolling contact with the ground, and a horizontal probe plate 2 is installed at the lower part of the mobile frame 3, The probe plate 2 is circular, and the axis of the probe plate 2 is consistent with the axis of the wellbore. Several wellbore probes 1 are evenly installed on the lower surface of the probe plate 2 around its own axis. Corresponding ultrasonic testing is carried out inside the wellbore.

[0043] refer to figure 2 and image 3 , the lower part of the mobile frame 3 is integrally formed with a horizontal frame lower plate 36, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com