Ignition insert with active prechamber

An insert and pre-chamber technology, applied in the direction of engine ignition, engine components, spark ignition controller, etc., can solve the problem that the cooling of the pre-chamber is difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

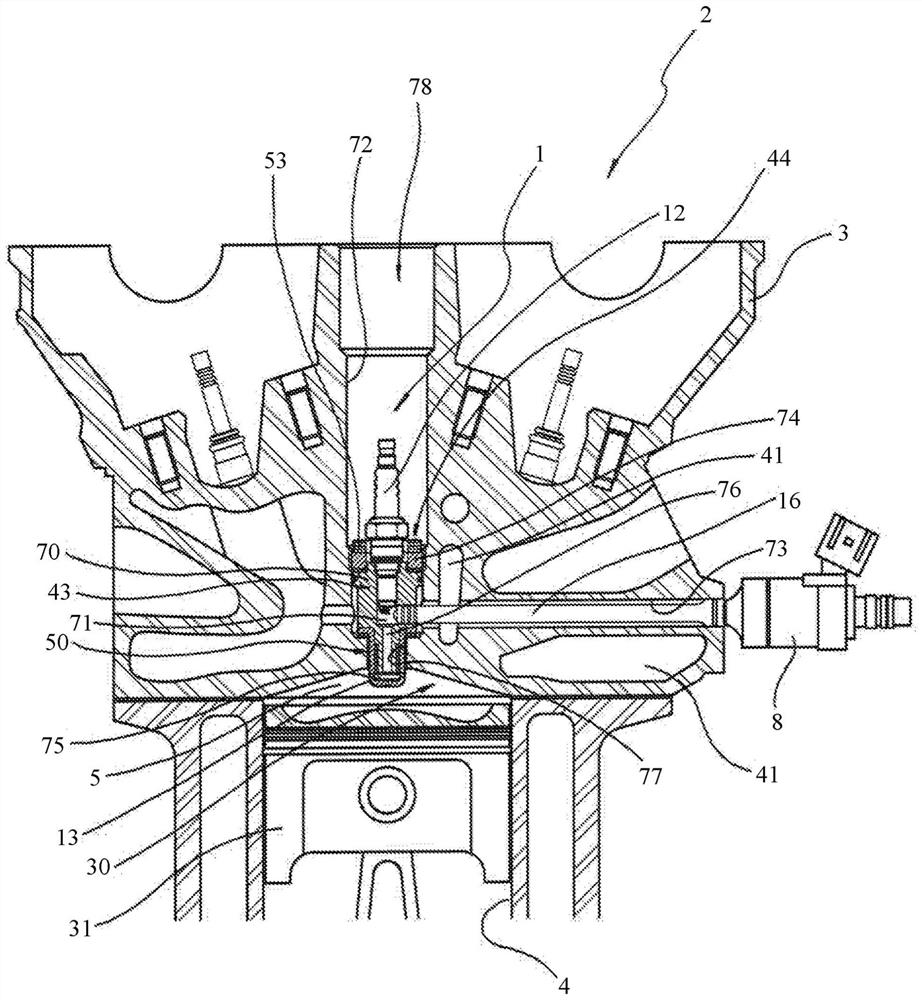

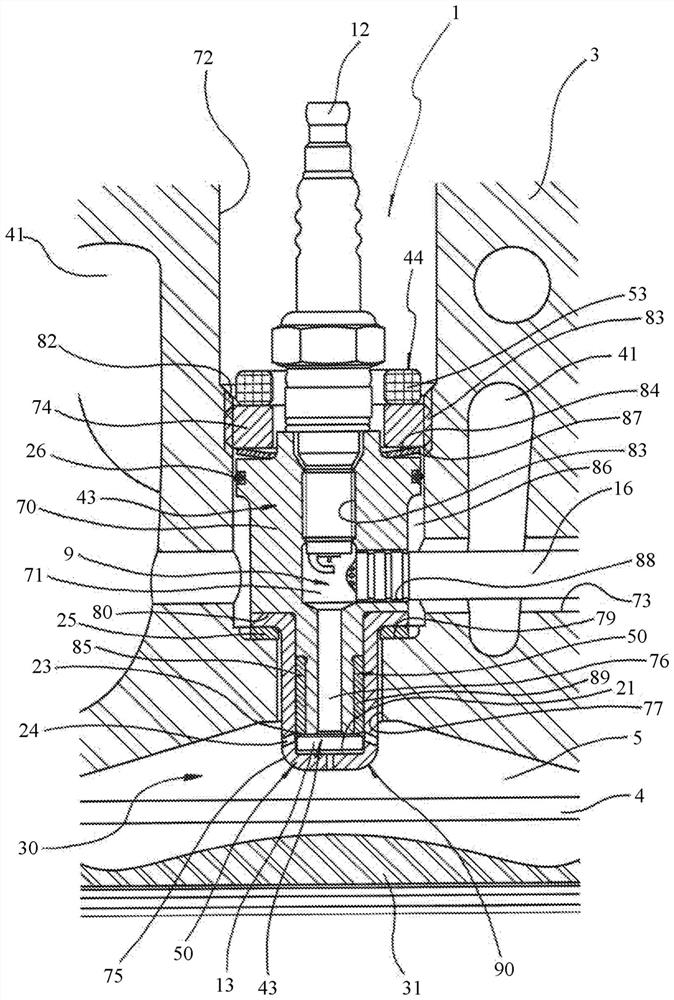

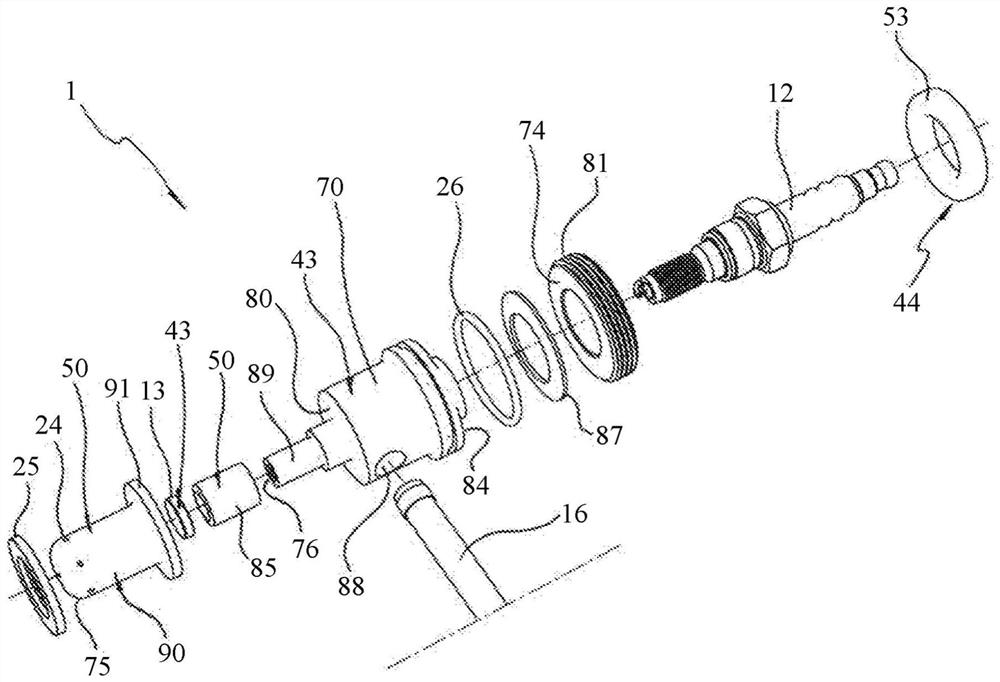

[0052] Figure 1 to Figure 6 The ignition insert with active pre-chamber 1 according to the invention, various details of its components, its alternative embodiments and its accessories are shown.

[0053] The ignition insert with active pre-chamber 1 is provided in particular for an internal combustion engine 2 comprising a cylinder head 3 covering a cylinder 4 to form, together with a piston 31 , a combustion chamber 5 into which a main load 30 can be introduced.

[0054] Such as figure 1 , figure 2 , Figure 5 with Image 6 As can be seen in the figure, the cylinder head 3 accommodates an ignition prechamber 71 into which the spark plug 12 and the injector nose 16 of at least one injector 8 open and into which the pilot charge 9 can be introduced, Said pre-chamber 71 can communicate continuously with the combustion chamber 5 via a gas ejection duct 76 and via at least one gas ejection orifice 24 which communicates via a pre-chamber nose 75 to the chamber 5.

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com