Sinking switch type floor drain

A switch-type, floor-drain technology, applied in the direction of fixed filter element, separation method, filtration separation, etc., can solve the problems of being stuck in the gap between the upper cover and the base, easily kicked by the toes, and troublesome to operate, etc. Achieve the effect of easy standardized preparation, reduced installation requirements, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

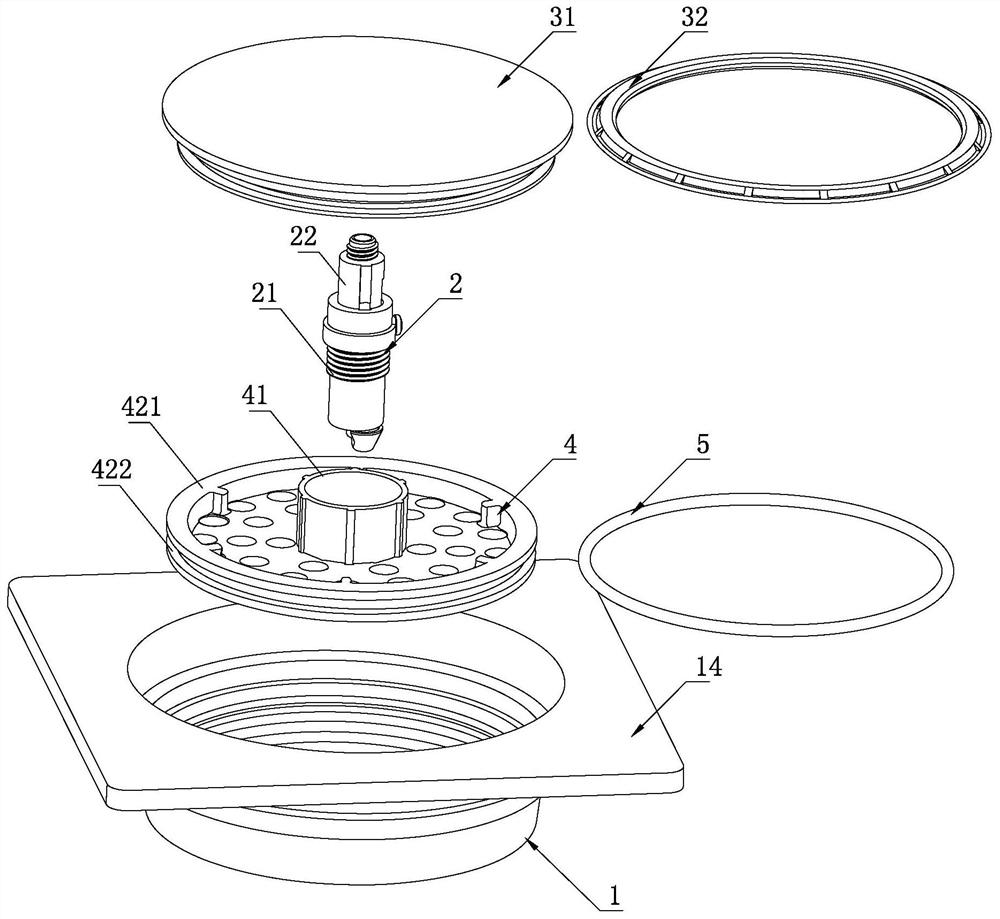

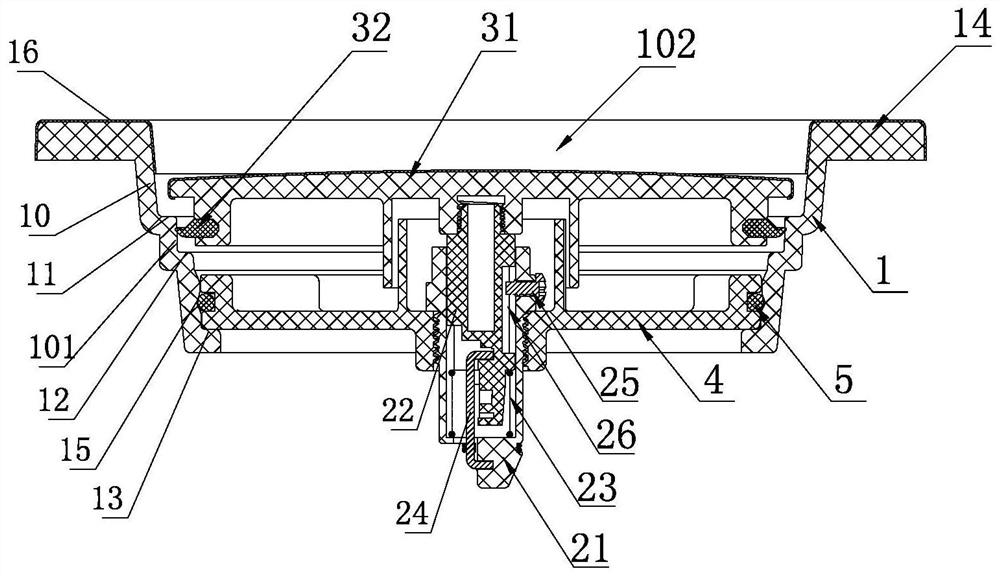

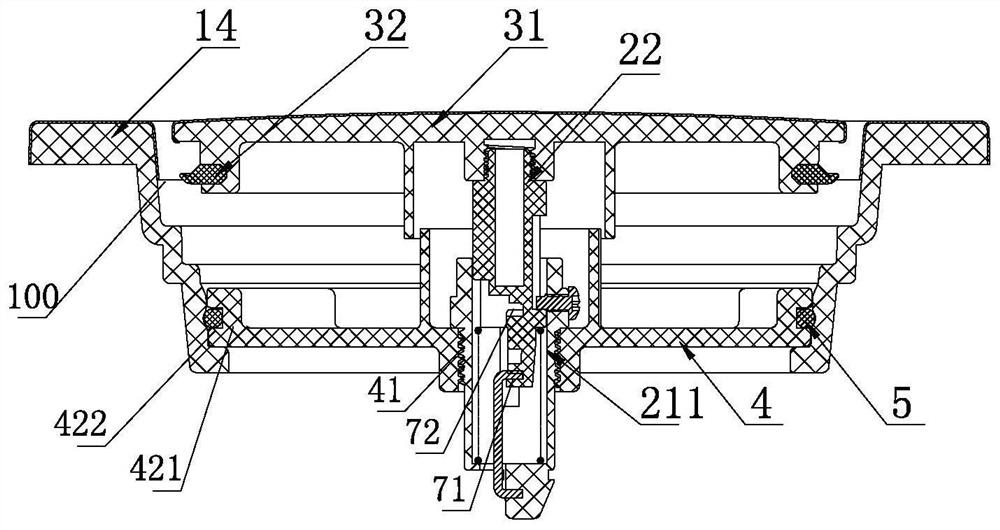

[0019] Refer to attached picture. The sinking switch type floor drain provided by the present invention includes a floor drain base 1 , a filter screen 4 , an upper cover device and a switch device 2 , and the floor drain base 1 has an inner hole 10 and a top mounting surface 14 . The base of the floor drain is connected to the applied ground or the bottom surface of the integral bathroom, and can be connected by bonding.

[0020] The switch device 2 includes a fixed part 21, an up and down moving part 22 and a jacking spring 23 thereof. The fixed part has a guide hole 211 for the up and down moving part 22 to move up and down. Jacking spring 23.

[0021] The upper cover device includes an upper cover 31 and a sealing ring 32 , wherein the upper cover 31 is screwed to the top of the up and down moving part 22 .

[0022] A lifting control mechanism is set between the fixed part 21 and the up and down moving part 22. The lifting control mechanism provides two stop positions up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com