Finite element analysis method for stress-strain relationship of sofa seat surface elastic material

A stress-strain, elastic material technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of lack of analysis methods, few studies on stress-strain relationship, etc., and achieve the effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

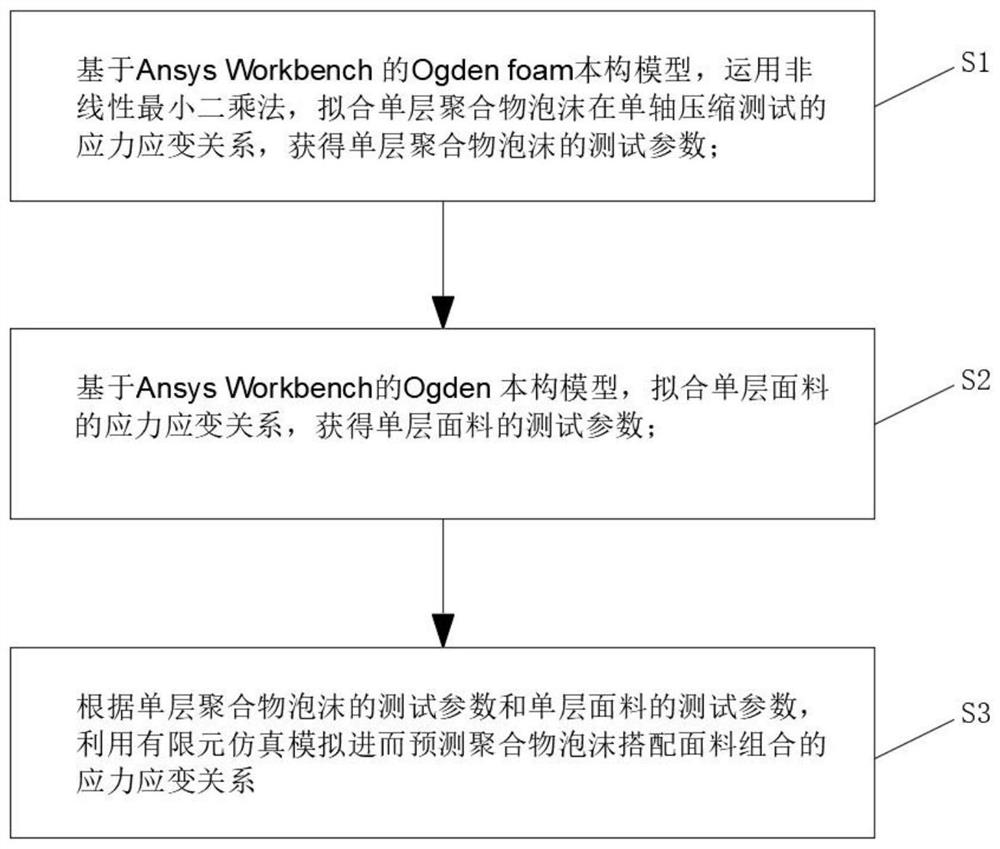

[0056] Embodiment: the finite element analysis method of the stress-strain relation of sofa seat surface elastic material, as figure 1 shown, proceed as follows:

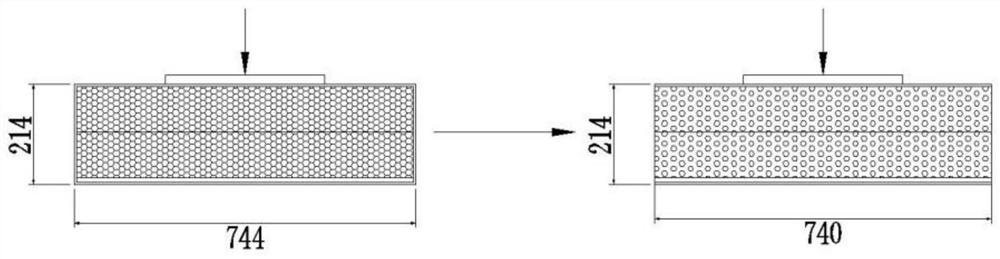

[0057] S1. Based on the Ogden foam constitutive model of Ansys Workbench, the nonlinear least squares method is used to fit the stress-strain relationship of the single-layer polymer foam in the uniaxial compression test, and the test parameters of the single-layer polymer foam are obtained; among them, the polymer The foams are polyether polyol foams (density 38kg / m 3 、25kg / m 3 ) and polyurethane foam (density 38kg / m 3 ), the size of the single-layer polymer foam specimen is selected as 740mmx740mmx100mm, and the single-layer polyether polyol foam with a density of 38kg / m3 is named Foam A, and the single-layer polyether polyol foam with a density of 25kg / m3 is named Foam B The single-layer polyurethane foam with a density of 38kg / m3 is named Foam C.

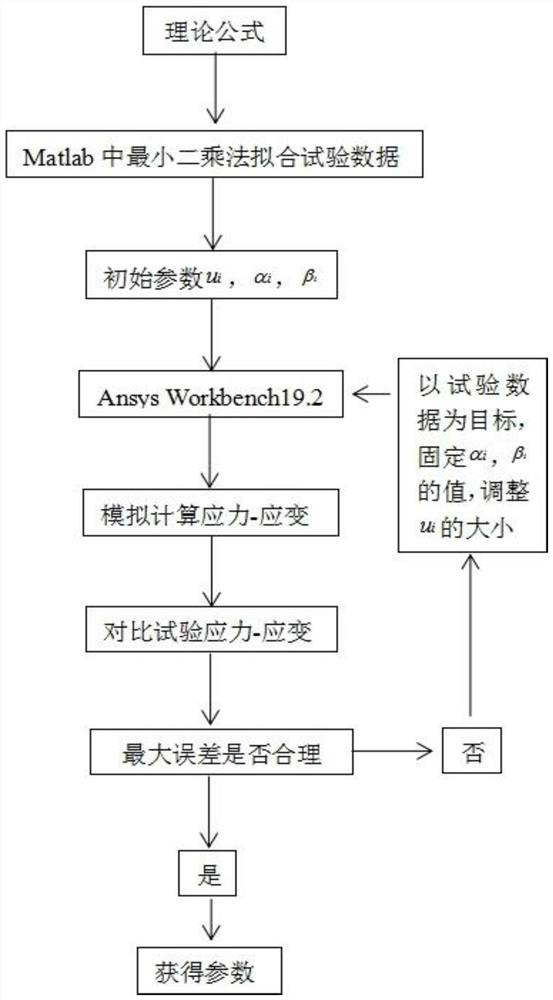

[0058] Specifically, in the Ogden foam constitutive model of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com