Discarded glass product crushing device for ophthalmology department

A glass product and crushing device technology, applied in grain processing and other directions, can solve problems such as low efficiency and easy occurrence of infection, and achieve the effect of avoiding abnormal opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

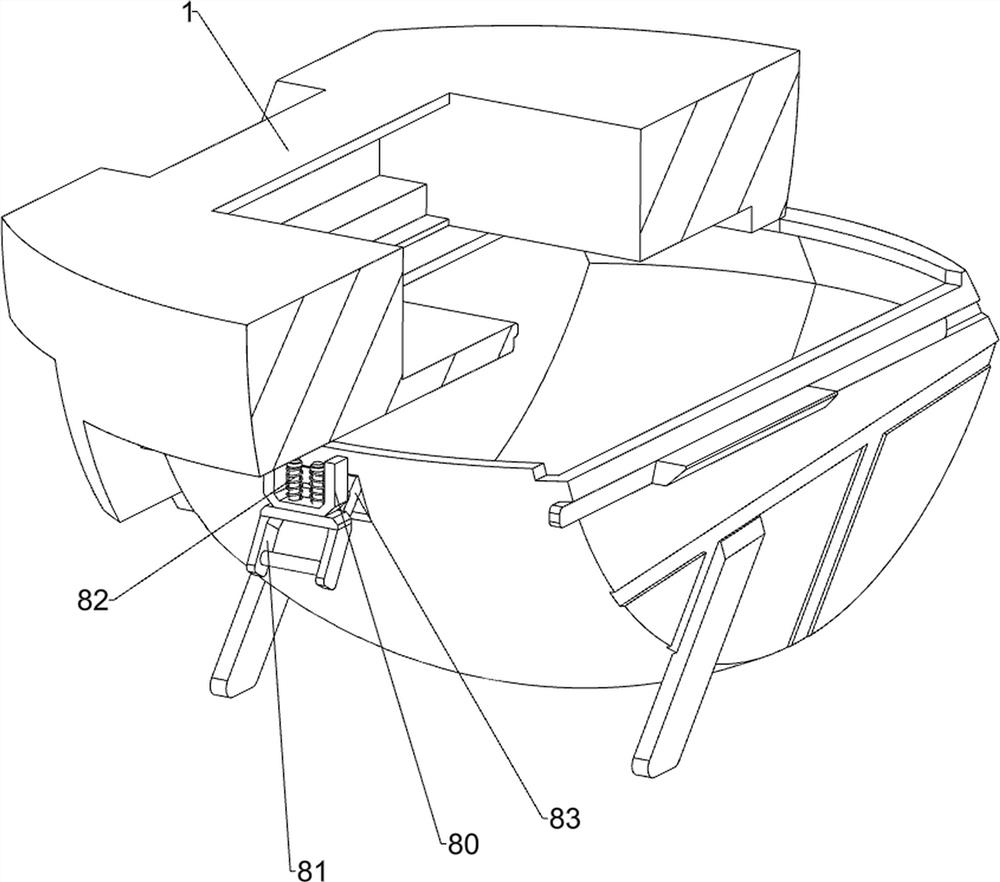

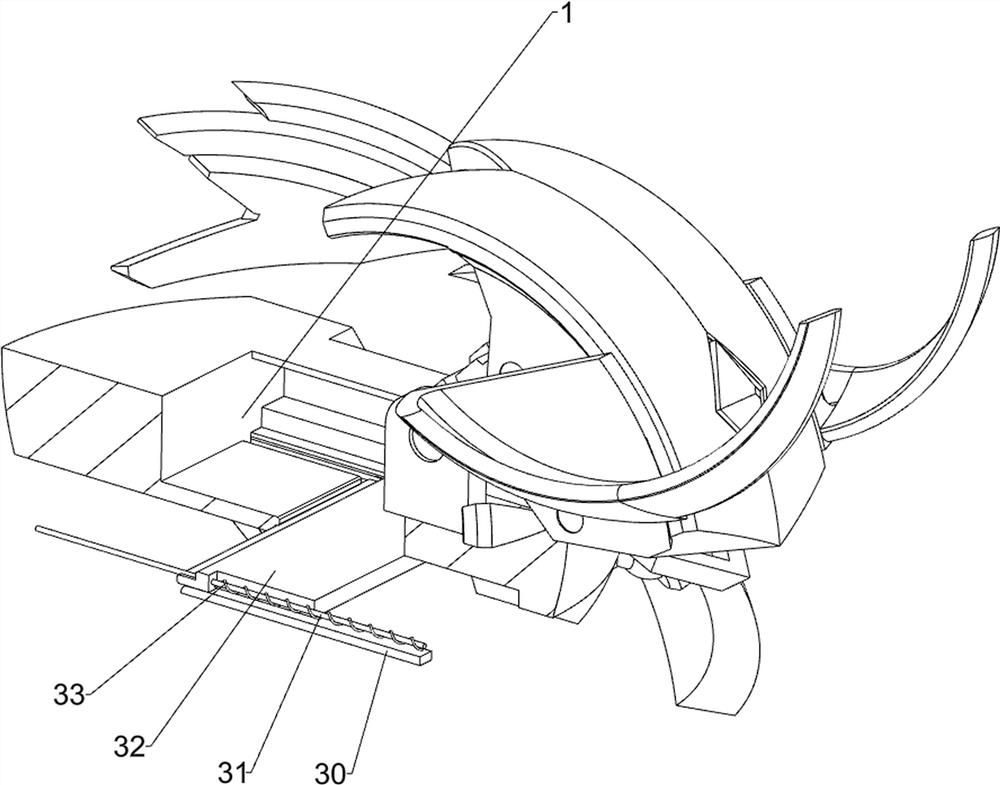

[0027] A crushing device for scrap glass products used in ophthalmology, such as Figure 1-9 As shown, it includes a placing frame 1, a supporting foot 2, a material retaining mechanism 3 and a crushing mechanism 4. The supporting feet 2 are symmetrically arranged on the front and rear sides of the placing frame 1, and the placing frame 1 is provided with a material retaining mechanism 3. 1 is provided with a crushing mechanism 4 .

[0028] When using the device, the staff puts the glass products that need to be crushed into the placement frame 1. After putting them away, the staff breaks the glass products through the crushing mechanism 4. After the crushing is completed, the staff opens the blocking mechanism 3, The crushed glass in the placing frame 1 falls down thereupon, and the worker collects it. After completion, the worker closes the stopper mechanism 3, so that scrap glass products that need to be crushed can be placed.

[0029] Such as figure 2 and image 3 As s...

Embodiment 2

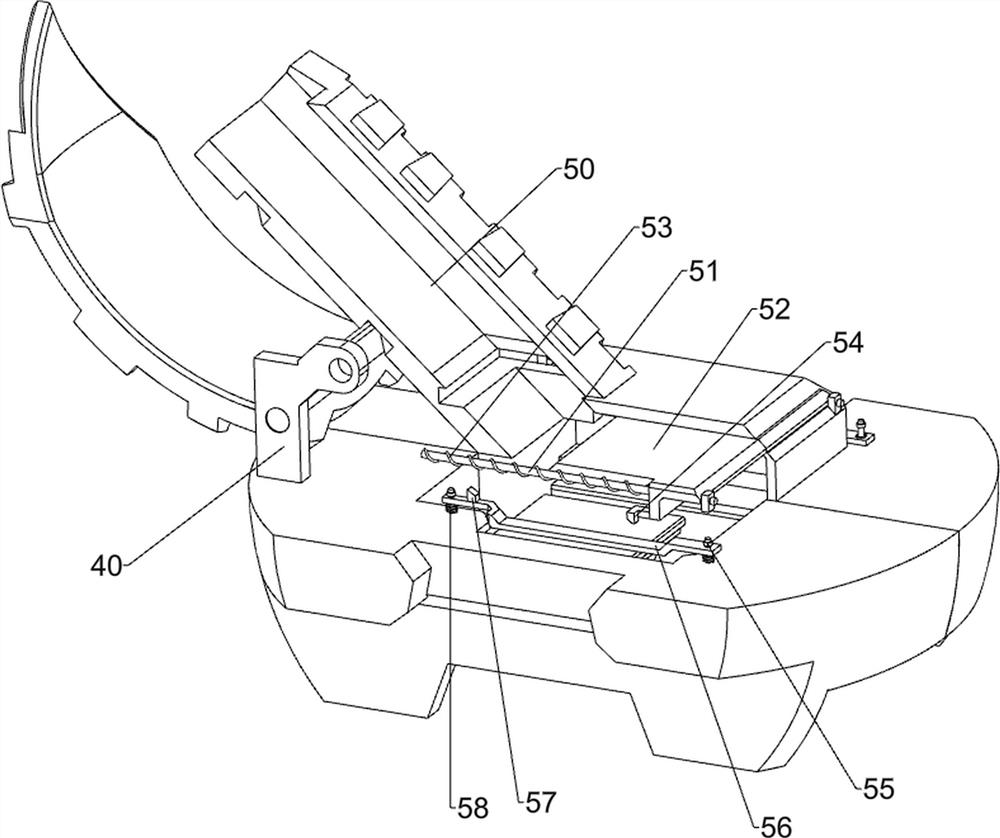

[0034] On the basis of Example 1, such as figure 1 figure 2 and Figure 6As shown, it also includes a blanking assembly 5, and the blanking assembly 5 includes a blanking hopper 50, a third guide rod 51, a second material baffle plate 52, a second spring 53, a first wedge block 54, and a fourth guide rod 55 , connecting rod 56, the second wedge block 57 and the third spring 58, the upper left side of the placement frame 1 is provided with a lower hopper 50, the upper and lower sides of the placement frame 1 are provided with a third guide rod 51, and the front and rear two third guides A second material retaining plate 52 is slidingly provided between the rods 51, and the second material retaining plate 52 cooperates with the first push plate 43, and a second spring is wound between the third guide rod 51 and the second material retaining plate 52 53, the first wedge-shaped block 54 is provided at the front and rear of the second material baffle plate 52, and the fourth gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com