A kind of electronic material spot welding equipment with anti-static function

A technology of electronic materials and spot welding equipment, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of manpower consumption, inconvenient operation, low efficiency, etc., and achieve the effect of improving feeding efficiency and preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

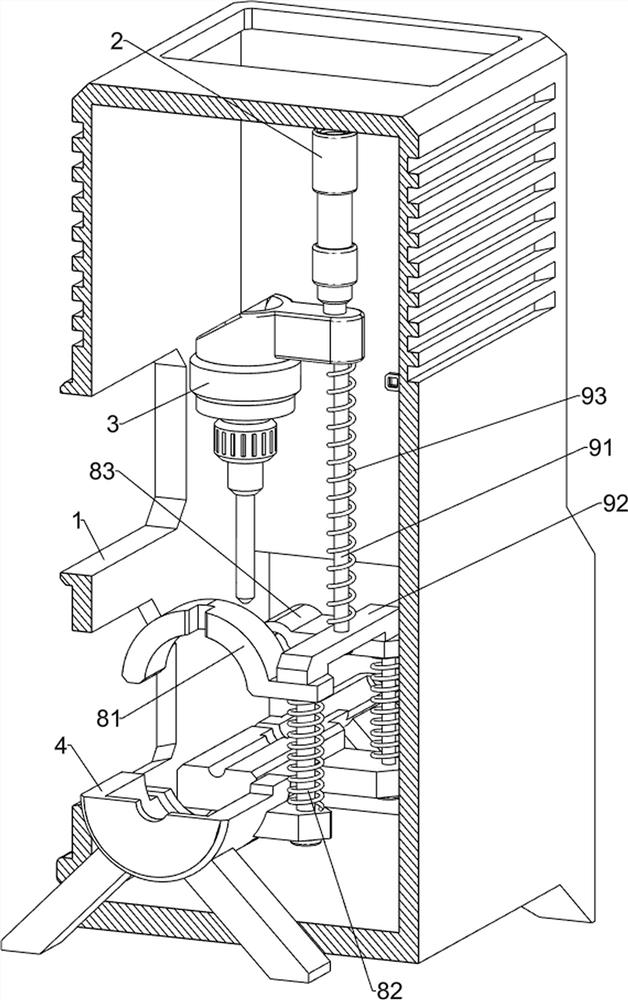

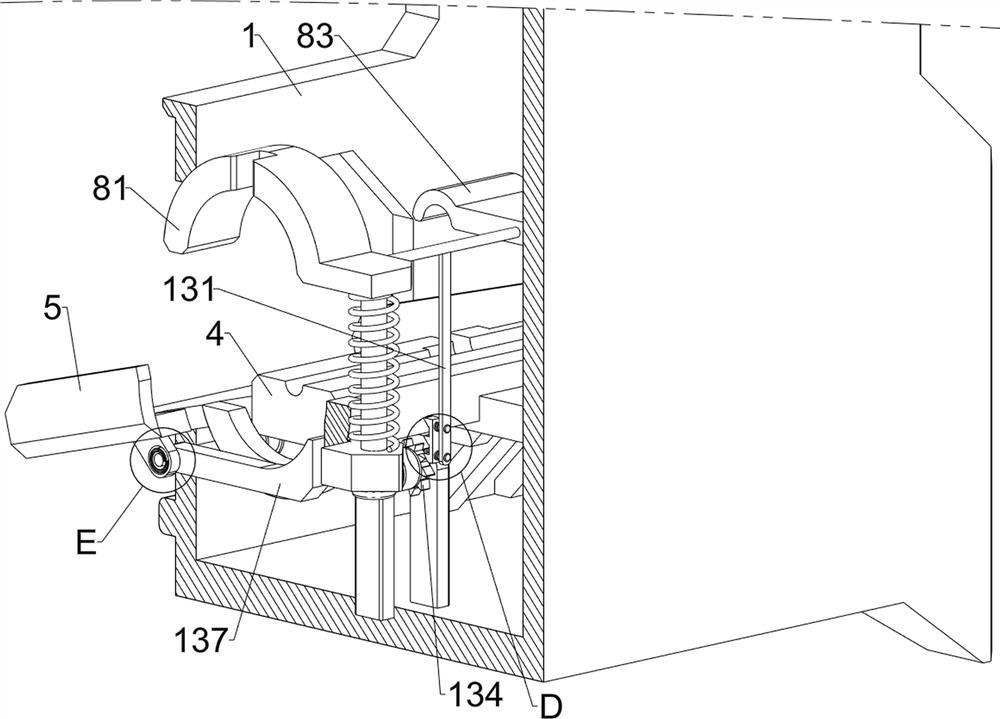

[0036] like Figure 1 to Figure 5 As shown in the figure, this embodiment discloses an electronic material spot welding equipment with anti-static function, including a casing 1, a cylinder 2, a spot welding machine 3, a placing plate 4, a discharging plate 5, an electrode rod 6, a static elimination host 7. The fixing assembly 8 and the pushing assembly 9, the cylinder 2 is installed in the middle of the upper rear side of the inner casing 1, the spot welding machine 3 is installed on the lower side of the piston rod of the cylinder 2, and the placing plate 4 is connected to the inner lower side of the casing 1, and the upper part of the placing plate 4 is in front of A discharge plate 5 is connected between the side and the front side of the lower part of the casing 1. An electrode rod 6 is installed in the middle of the lower right side of the casing 1. The main engine 7 is connected, a fixing component 8 is arranged on the rear side of the upper part of the placing plate 4...

Embodiment 2

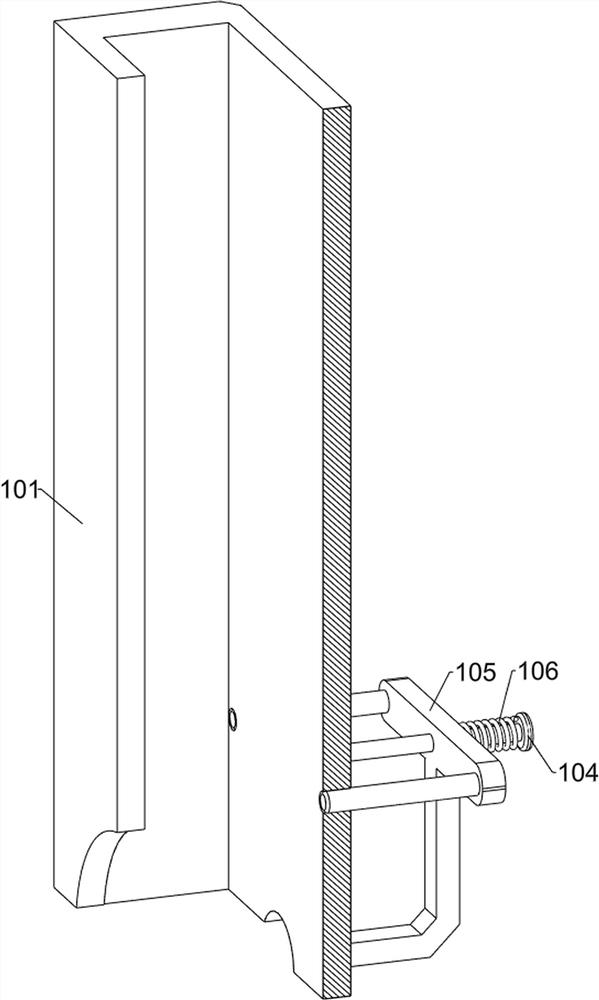

[0041] like figure 1 , figure 2 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, in some embodiments, a feeding assembly 10 is also included, and the feeding assembly 10 includes a first blanking plate 101, a second guide rod 102, a first storage frame 103, a third guide rod 104, a A clamping rod 105, a fourth spring 106, a second blanking plate 107, a second material storage frame 108, a second clamping rod 109 and a fifth spring 110, and the first blanking plate 101 is connected to the right side of the inner middle of the housing 1. The lower side of the first blanking plate 101 is connected with the placing plate 4 , the lower right side of the first blanking plate 101 is connected with a third guide rod 104 , and the third guide rod 104 is slidably connected with a first clamping rod 105 . The clamping rod 105 is slidably connected with the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com