Electronic material spot welding equipment with anti-static function

A technology for electronic materials and spot welding equipment, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of labor-intensive, inconvenient operation, affecting the normal progress of spot welding, etc., to improve the feeding efficiency and prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

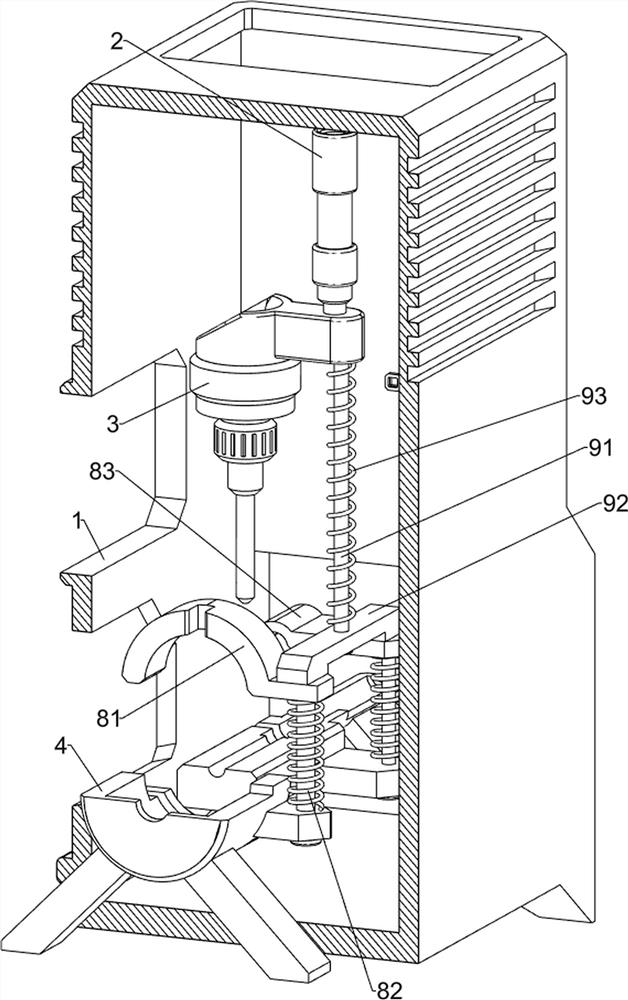

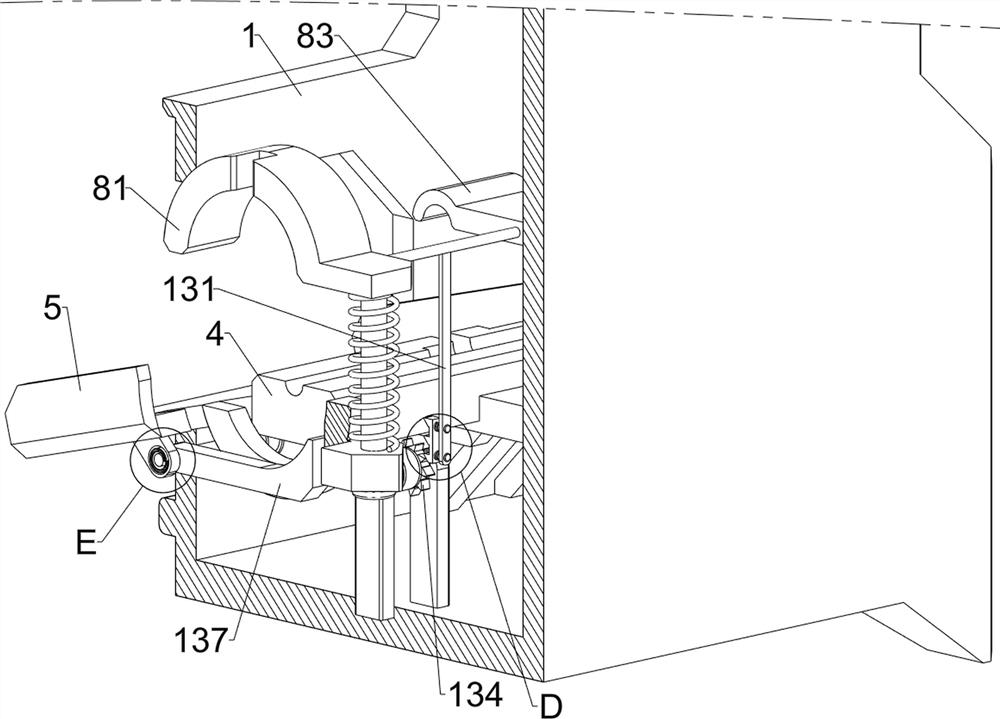

[0036] like Figure 1 ~ 5 , The spot welding equipment, an electronic material with antistatic function of the present embodiment, comprises a housing 1, a cylinder 2, 3 spot welding, placing plate 4, the plate 5, the electrode rod 6, in addition to static host 7, 8 and drive assembly fixing assembly 9, the upper portion of the rear side of the intermediate housing 1 is attached to the cylinder 2, the piston rod of the cylinder 2 a little lower attachment welder 3, the interior of the housing 1 is connected to the side plate 4 is placed, placing an upper front plate 4 the lower front side of the housing 1 is connected between the side plate 5, the lower portion of the right side of the intermediate housing 1 is attached to the electrode rod 6, a lower portion of the right rear housing 7 attached to the host electrostatic electrode rod 6 and the right side of the static eliminating inter 7 is connected to the host, the upper portion of the rear plate 4 is placed a fixing unit 8, a l...

Embodiment 2

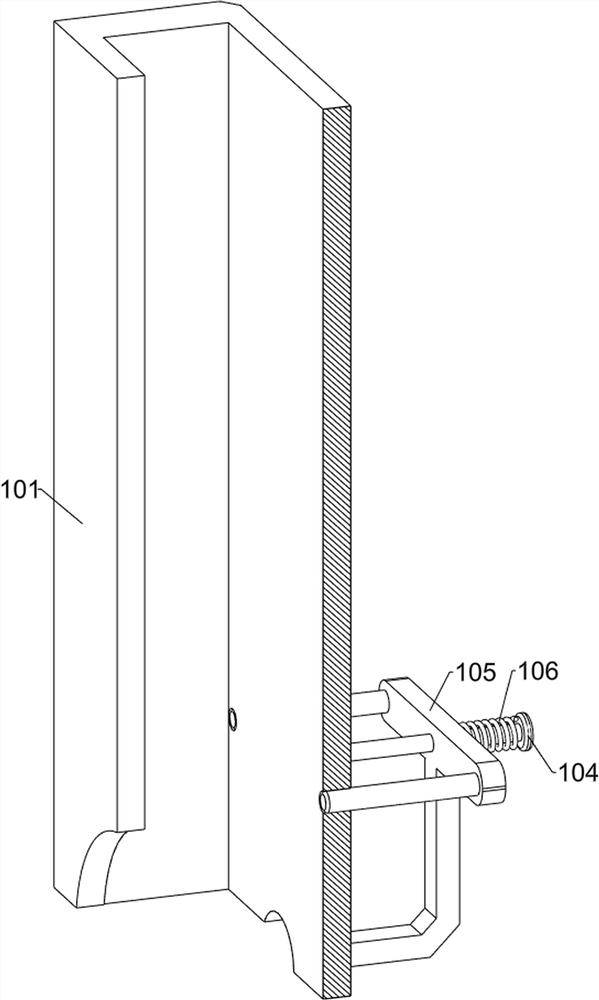

[0041] like figure 1 , figure 2 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 , In some embodiments, further comprising a feed assembly 10, the feed assembly 10 includes a first blanking plate 101, a second guide bar 102, a first material storage frame 103, third guide bar 104, a card lever 105, fourth spring 106, the second cutting plate 107, second accumulator block 108, second levers 109 and the fifth spring 110, the housing 1 is connected to the middle of the right plate 101 of the first cutting, cutting a first side of the plate 101 is placed lower plate 4 is connected to the right side of a first blanking plate 101 is connected to a lower third guide bar 104, the third guide rod 104 slidably connected to the first levers 105, a first card 105 is connected to the rod material at a first sliding plate 101, a fourth spring 106 is connected between the first levers 105 and the third gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com