Efficient grinding device based on optical lens

An optical lens, high-efficiency technology, used in optical surface grinders, grinding drives, grinding/polishing safety devices, etc., can solve problems such as hidden safety hazards and cumbersome operations, and achieve the effect of efficient grinding and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

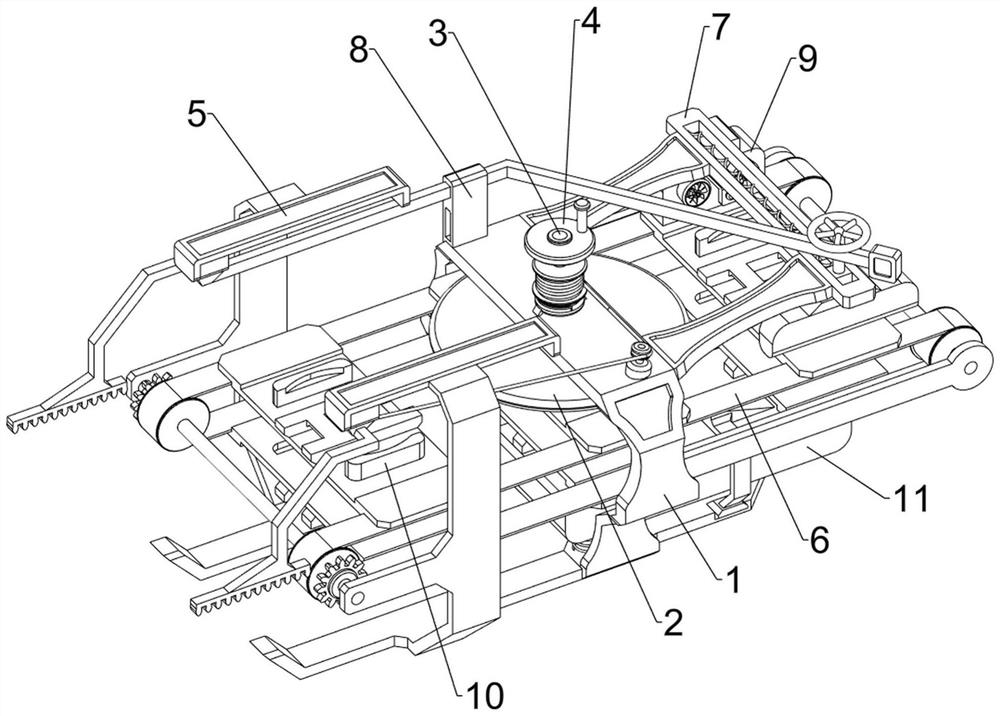

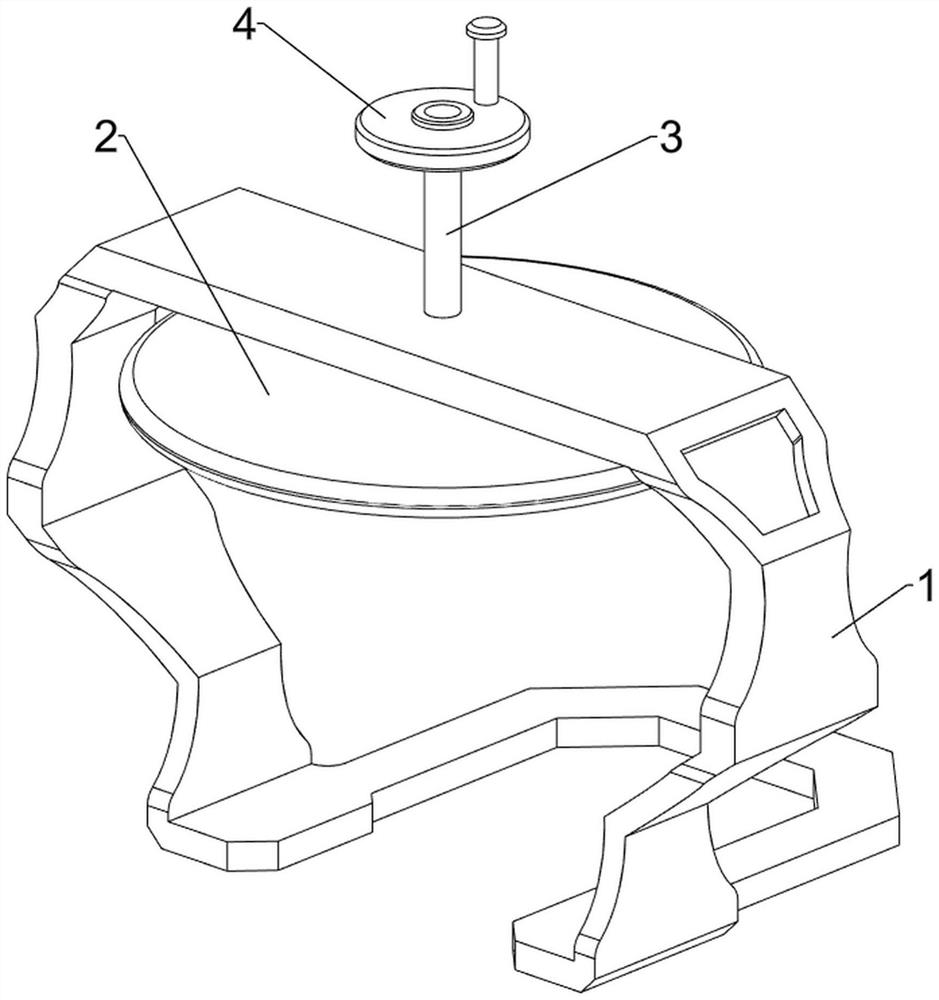

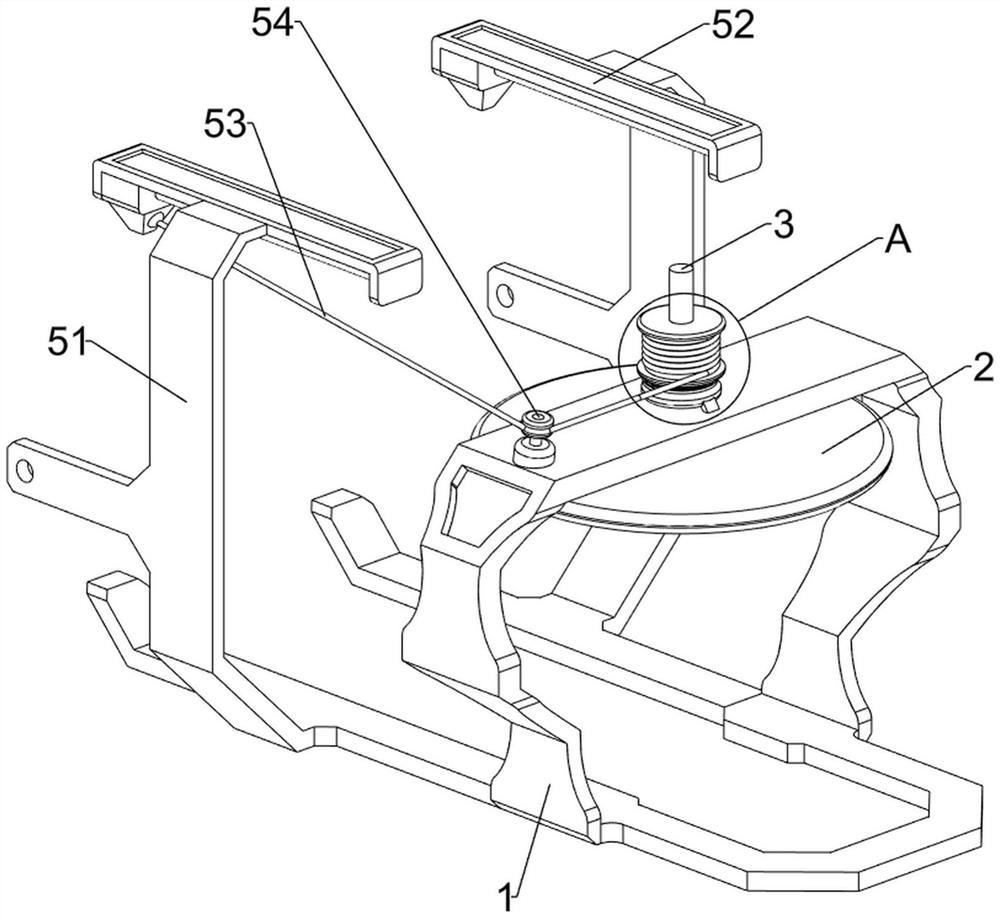

[0036] A high-efficiency grinding device based on optical lenses, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 12 with Figure 13 As shown, it includes a connecting frame 1, a grinding disc 2, a rotating shaft 3, a rotating disk 4, a rotating mechanism 5, a conveying mechanism 6 and a clamping mechanism 10, and the middle position on the left side of the connecting frame 1 is rotatably connected with a rotating shaft 3. The bottom is welded with a grinding disc 2, the upper part of the rotating shaft 3 is riveted with a turntable 4, a rotating mechanism 5 capable of rotating is connected between the connecting frame 1 and the rotating shaft 3, and an optical lens is connected between the connecting frame 1 and the rotating mechanism 5. As for the conveying mechanism 6, a clamping mechanism 10 is connected to the conveying mechanism 6 to facilitate positioning of the optical lens.

[0037]Swivel mechanism 5 comprises connecting pla...

Embodiment 2

[0042] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 Shown, also comprise wiping mechanism 7, and wiping mechanism 7 comprises support plate 71, guide rail 72, slide bar 73 and sponge wipe 74, and two support plates 71 are welded symmetrically on the front and rear sides of connecting frame 1 top right side, two Be connected with the guide rail 72 that can be used for sliding guide between the right side of block support plate 71, the inboard sliding type of guide rail 72 is provided with slide bar 73, and the bottom of slide bar 73 is detachably installed with the sponge wipe 74 that can be used for wiping.

[0043] Also includes a power mechanism 8, the power mechanism 8 includes a second connecting rod 81, a fixed block 82 and a first spring 83, the rear side of the connecting frame 1 top is connected with a fixed block 82 by means of bolt connection, the top of the fixed block 82 The sliding type is connec...

Embodiment 3

[0047] On the basis of Example 2, such as figure 1 , Figure 14 with Figure 15 As shown, a receiving mechanism 11 is also included, and the receiving mechanism 11 includes a third spring 111, a charging frame 112 and a wedge block 113, and the inner bottom of the connecting frame 1 is connected with a charging frame 112 through a plurality of third springs 111 Wedge blocks 113 are symmetrically welded on the front and back sides of the right side of the connecting frame 1 , and the two wedge blocks 113 are in contact with the elastic splint 101 .

[0048] When the operator needs to collect the optical lenses that have been wiped, the optical lenses can be transported to the charging frame 112 under the transmission of the flat belt 66, and when the elastic splint 101 contacts and cooperates with the wedge block 113, it can be pushed Elastic splint 101 slides up and makes optical lens break away from groove 102, and second spring 103 shrinks thereupon, and optical lens falls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com