High-efficiency package printing method

A packaging printing, high-efficiency technology, applied in the direction of printing, printing machines, rotary printing machines, etc., can solve the problems of inability to adjust the adjustment of the guide height, reduce efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

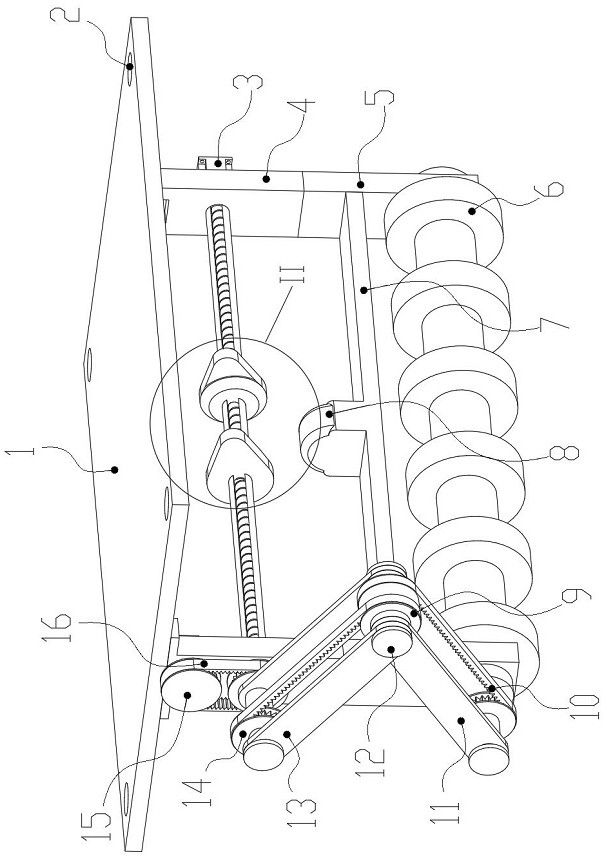

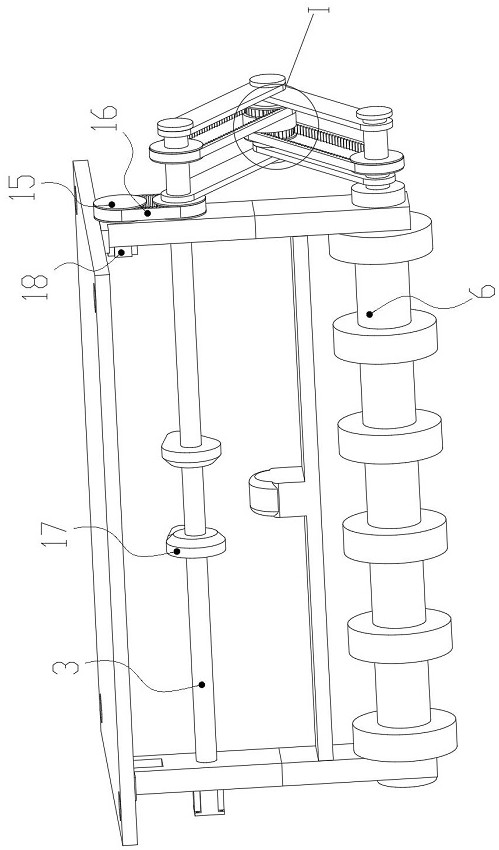

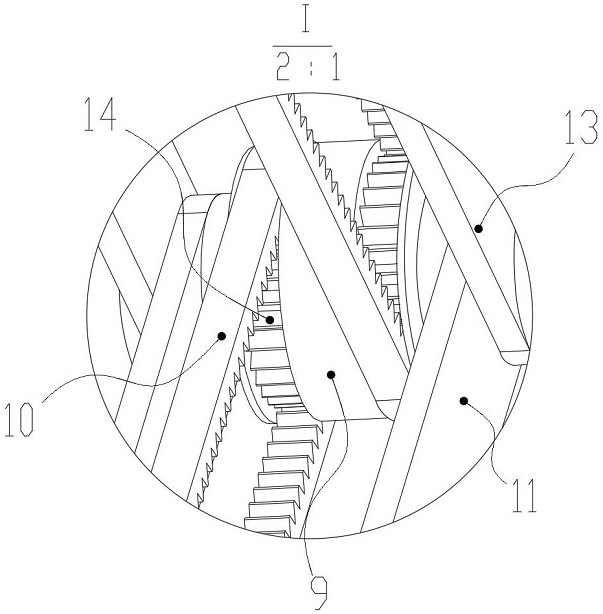

[0044] like Figure 1-9 As shown, it is the first embodiment of the present invention: a high-efficiency packaging printing device, including a mounting support plate 1, a threaded hole 2, an adjustment mechanism 3, a supporting side plate 4, a supporting bottom plate 5, a positioning connecting roller 6, an installation Bracket 7, limit block 8, double pulley 9, first installation connecting plate 11, limit insertion shaft 12, second installation connecting plate 13, toothed pulley 14, transmission pulley 15, second toothed belt 16, positioning Mechanism 17, connecting motor 18 and spring clamping shaft 19,

[0045] The upper end surface of the installation support plate 1 is evenly and equidistantly provided with four sets of threaded holes 2 for positioning, and the lower end surface of the installation support plate 1 is symmetrically fixedly connected with the support side plate 4 for positioning, and is located on the side of the support side plate 4. The side end surfa...

Embodiment 2

[0050] On the basis of Example 1, such as Figure 10 As shown, the connecting wheel shaft 171 is arranged in a circular shape, and rounded corners are provided on the sides of the connecting wheel shaft 171 for limiting positions.

[0051] When this embodiment is in use, if the user needs to always adjust the height of the device to guide the printed product, the user can move the two sets of positioning mechanisms 17 closer by performing the above steps, and the connecting wheel shaft 171 arranged in a circle can pass through the connection. The angle 173 presses the limit block 8 to the outside, and the closer the two sets of positioning mechanisms 17 are, the higher the displacement height of the positioning connecting roller 6 is pressed to the outside, which improves the conveying efficiency and adaptability of the device.

[0052] Utilize the equipment of embodiment 1 and embodiment 2 to implement efficient package printing process, its steps are as follows:

[0053] S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com