Automatic feeding device for synthetic polymer waterproof coiled material

A technology for synthesizing polymers and waterproofing membranes, which is applied to tools used in roofing engineering, roofing, construction, etc., can solve problems such as insufficient adhesion of waterproofing membranes, and achieve the effect of improving efficiency and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

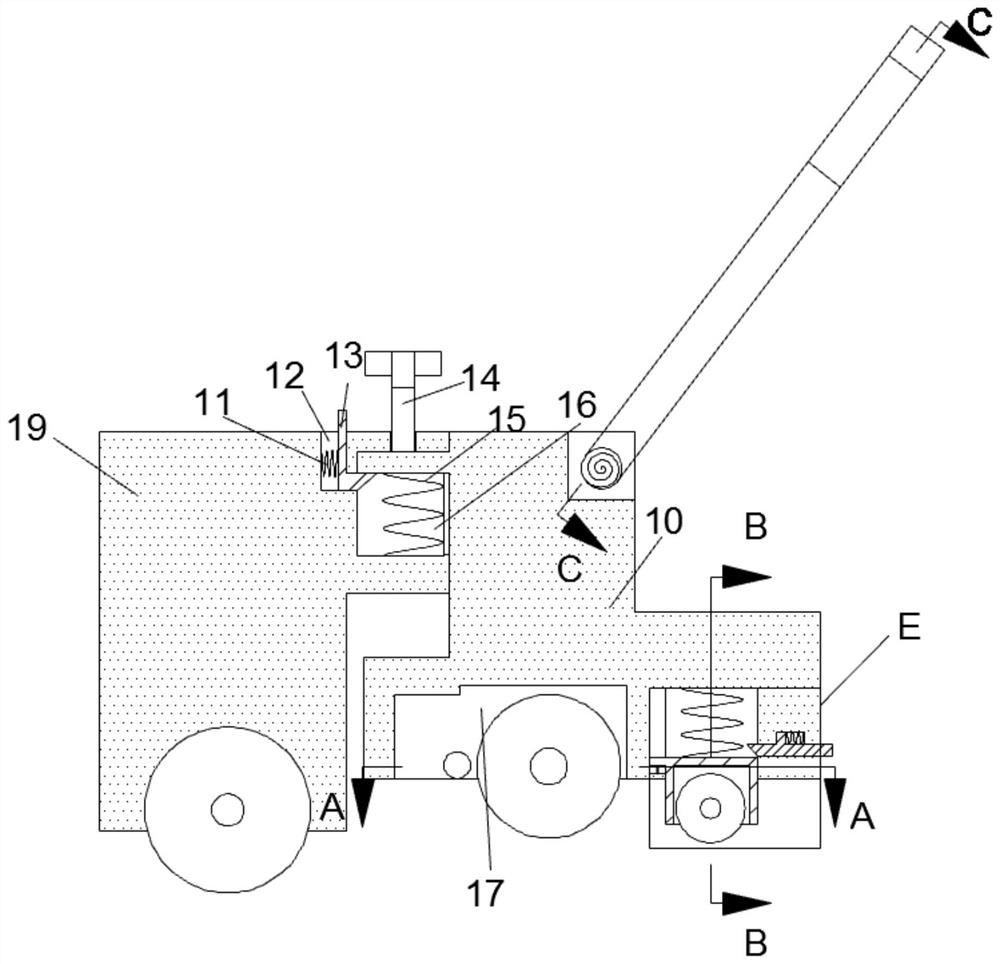

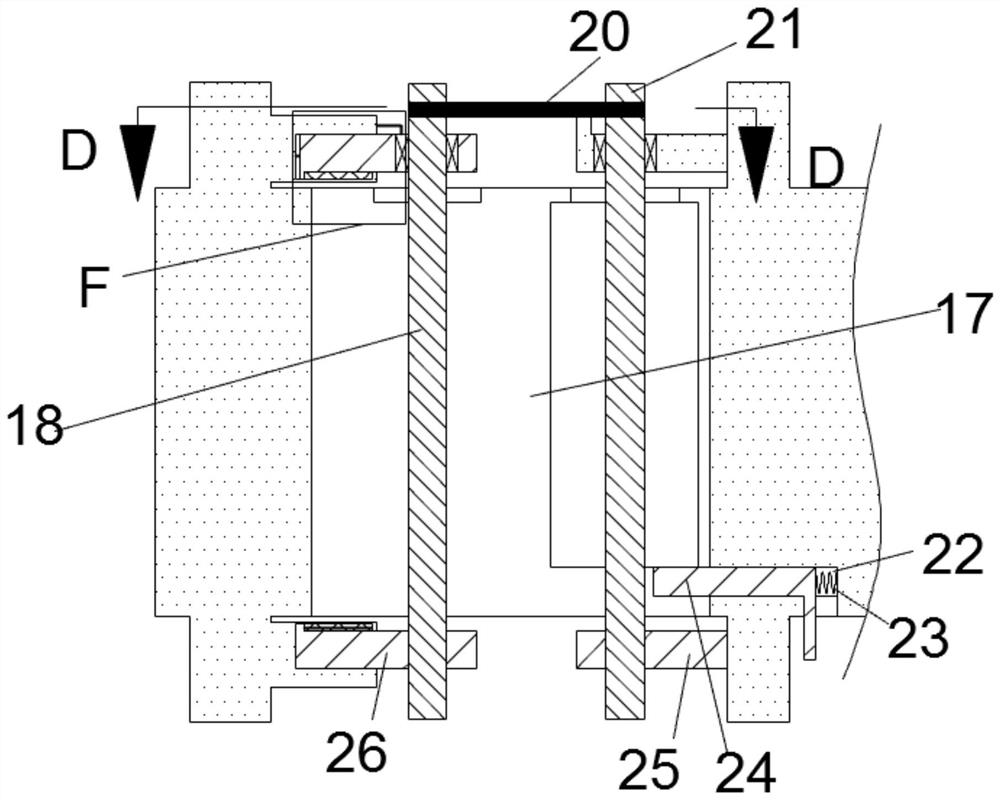

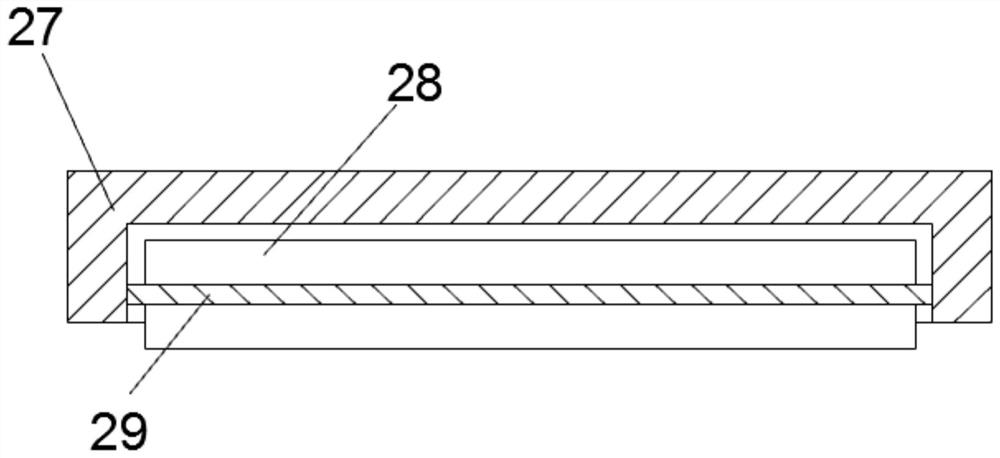

[0026] Combine below Figure 1-8 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0027] combined with Figure 1-8 The automatic supply device for a synthetic polymer waterproof coiled material includes a body 10 and a vehicle body 19, a fixing assembly that is arranged on the body 10 to fix the self-adhesive waterproof coiled material, and is installed on the body 10 to be laid The pressing assembly for pressing the self-adhesive waterproof roll material and the roof surface is arranged on the body 10 for tearing the film tearing of the self-adhesive waterproof roll material film. The pasting assembly, the thick rope 44, and the laying assembly for laying the self-adhesive waterproof membrane, when the laying assembly is laying the self-adhesive waterproof membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com