Partition perforated square tube space sound absorber

A sound-absorbing body and space technology, applied in the direction of sound insulation, insulating layer, floor, etc., can solve the problems of reduced sound absorption effect, complicated installation, indoor environmental pollution, etc., to achieve the effect of sound absorption effect and reduce construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

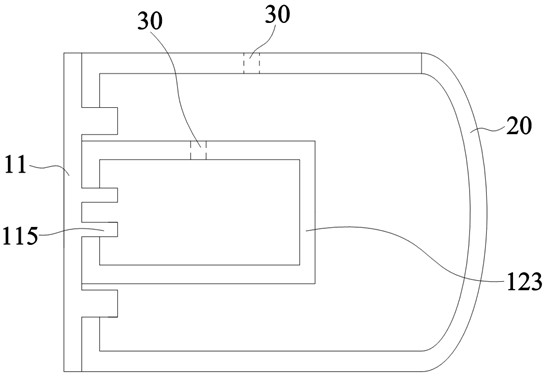

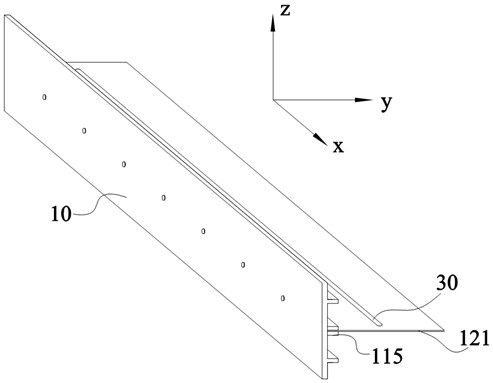

[0072] Such as figure 1 and Figure 4 As shown, in the embodiment, the keel assembly 10 includes a flat first partition 121 . The first partition 121 is extended along the length direction of the keel body 11 , the first partition 121 is perpendicular to the keel body 11 , and the first partition 121 is parallel to the first panel 21 . One side of the first partition 121 can be connected with the keel body 11 , and the other side of the first partition 121 can be connected with the second panel 22 . The first partition 121 can divide the cavity separating the inside of the perforated square space sound absorber into two sub-cavities, one of which is close to the first panel 21 , and the other is close to the third panel 23 . In some specific embodiments, the length of the first partition 121 may be equal to the length of the keel body 11 .

[0073]In the embodiment, a pair of symmetrical limiting plates 115 are provided on the side of the keel body 11 close to the square ch...

Embodiment 2

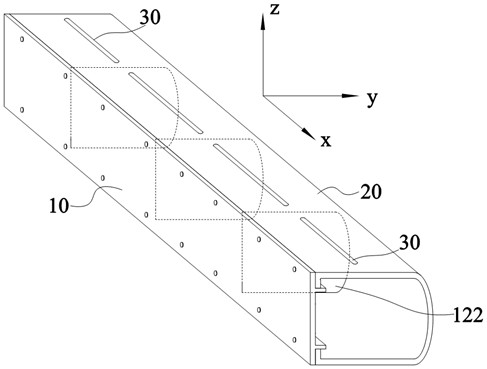

[0078] Such as Figure 5 As shown, the keel assembly 10 includes three flat second partitions 122 . The three second partitions 122 are spaced apart from each other and arranged in parallel. In some specific embodiments, the second partition 122 is perpendicular to the keel body 11 and the first panel 21 at the same time. Meanwhile, one side of the second partition 122 can be connected to the keel body 11 , and the other three sides of the second panel 22 can be respectively connected to the first panel 21 , the second panel 22 and the third panel 23 at corresponding positions. Correspondingly, the three second partitions 122 can divide the perforated rectangular sound absorbing body into four sub-cavities.

[0079] In some other embodiments, the position between the first partition 121 and the keel body 11 may also be non-perpendicular.

[0080] In the embodiment, corresponding to the position of any sub-cavity, a slit 30 is provided on the first panel 21 for connecting th...

Embodiment 3

[0084] Such as Figure 6 As shown, in some embodiments, the keel assembly 10 includes a third partition 123 with a U-shaped cross section. The shape of the third partition 123 can be substantially the same as that of the square channel assembly 20. One side of the plate 123 can also be provided with an opening structure, wherein the cross section of the third partition 123 can be seen as the cross section of the third partition 123 on the y-z plane. It can be understood that the cross-sectional size of the third separator 123 on the y-z plane may be smaller than the cross-sectional size of the square channel assembly 20 on the y-z plane.

[0085] In an embodiment, a pair of symmetrical limiting plates 115 is provided on the side of the keel body 11 close to the square channel assembly 20 , and the third partition 123 can be provided at the positions of the two limiting plates 115 . The two limiting plates 115 can be inserted into the openings of the third partition 123 and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com