Shaping device for motor alloy end cover after stretching and stamping

A shaping device and alloy technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of affecting the polishing quality, the grinding force is large, and it is difficult to ensure the stability of the motor end cover, so as to ensure the processing stability and Mass, increased stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] In order to make the technical problems, technical solutions, and advantages to the present invention, the technical solutions and advantages will be described in detail below with reference to the accompanying drawings and specific embodiments.

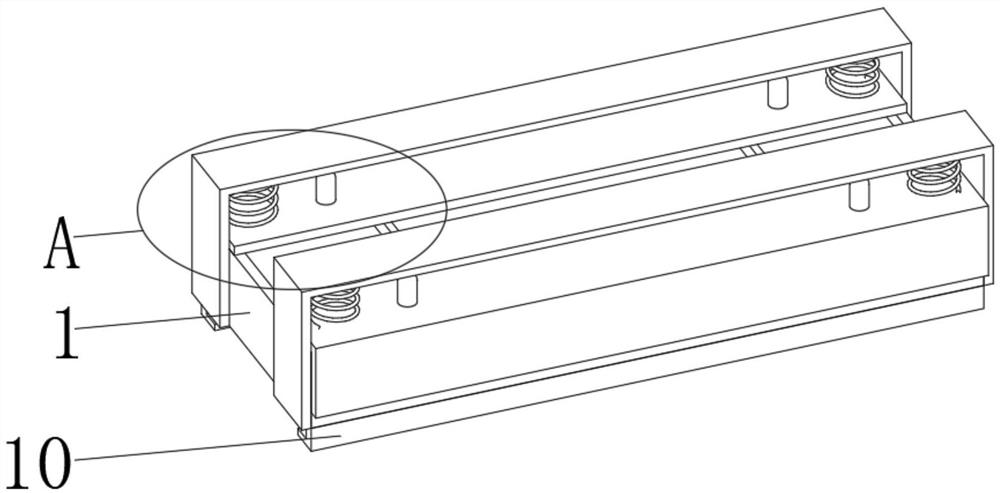

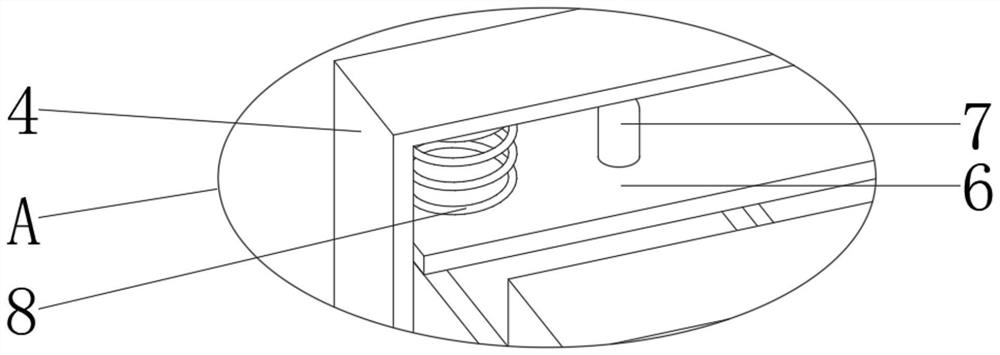

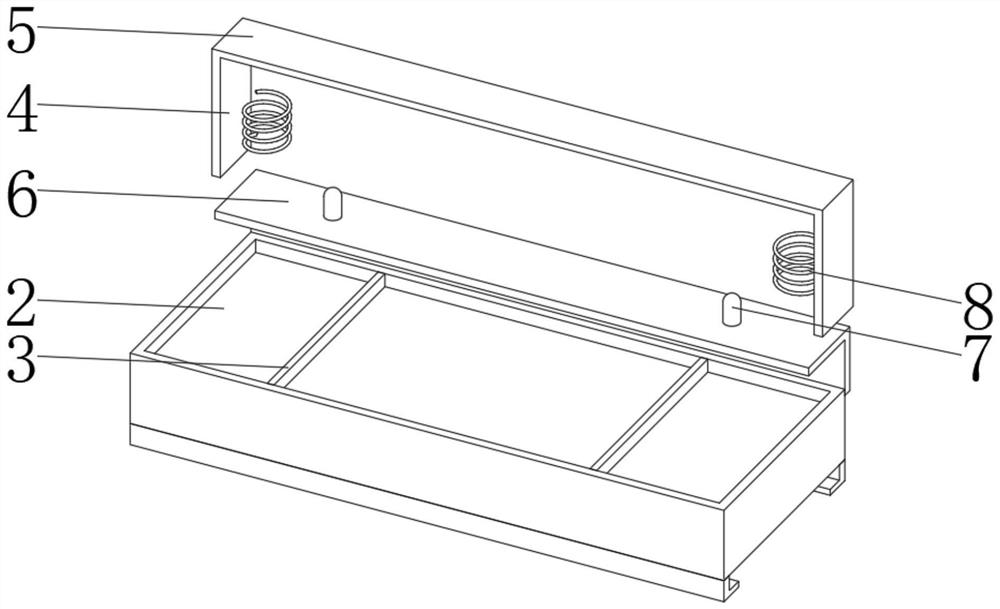

[0023] Append figure 1 Attachment Figure 5 Embodiments of the present invention provide a motor alloy end cap stretching stamping device, including a fixing case 1, the top surface of the fixing case 1 has a fixed limit inner groove 2, the fixed limit inner groove 2 The inner wall surface is mounted with a fixed separator 3, and one side of the fixing case 1 is detachable and attached to the fixed side plate 4, and the top end of the fixed side panel 4 is integrally formed with a fixed plate 5, the fixed plate 5 The bottom end is mounted with a telescopic spring 8, and the other end of the telescopic spring 8 is mounted in a movable bottom plate 6, and the tip end of the movable bottom plate 6 is fixedly mounted for the finite cyl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap