Battery case automatic, continuous and ordered arranging and conveying device and method

A battery casing and conveying device technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of automatic, continuous, neat arrangement and transportation of battery casings that are not mentioned, and reduce labor costs and labor. Strength, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

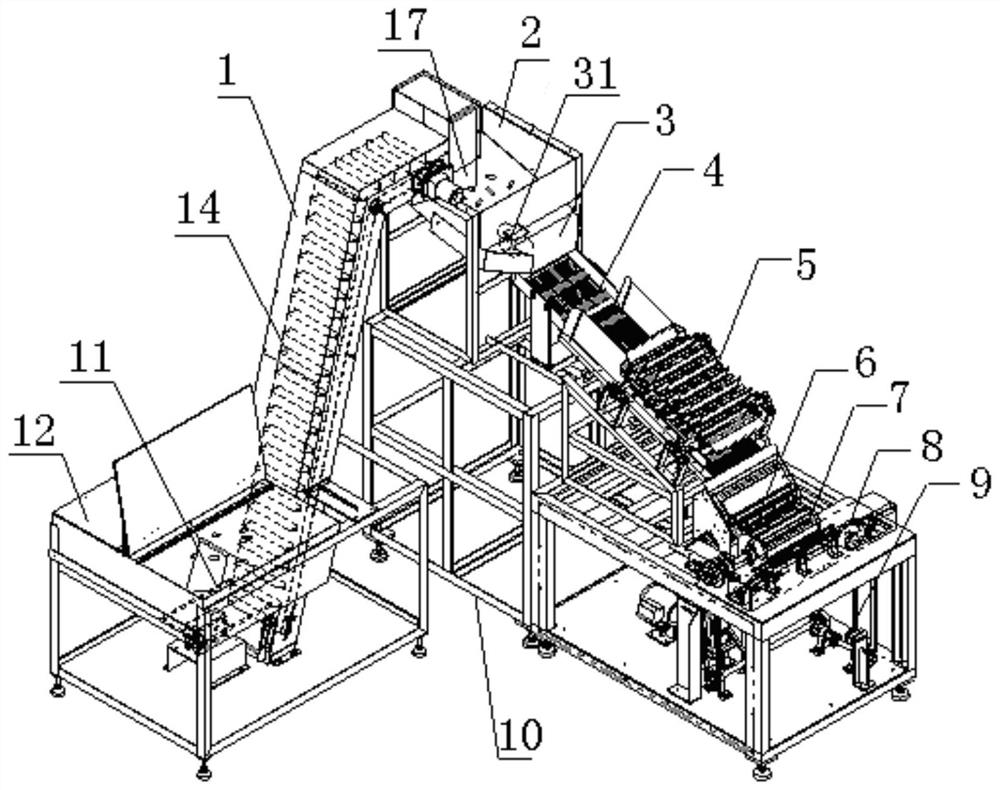

[0038] The battery casing automatic continuous and neatly arranged conveying device provided by the present invention includes a frame 10, feeding mechanisms 1 and 2 successively arranged on the frame 10, a vibrating feeding chute 3, a comb-toothed chute 4, and reverse feeding Device 5, step-by-step feeder 6, equal roller feeder 7, chain pusher 8, power mechanism 9, wherein the feeding mechanism includes elevator 1 and drop hopper 2, such as figure 1 .

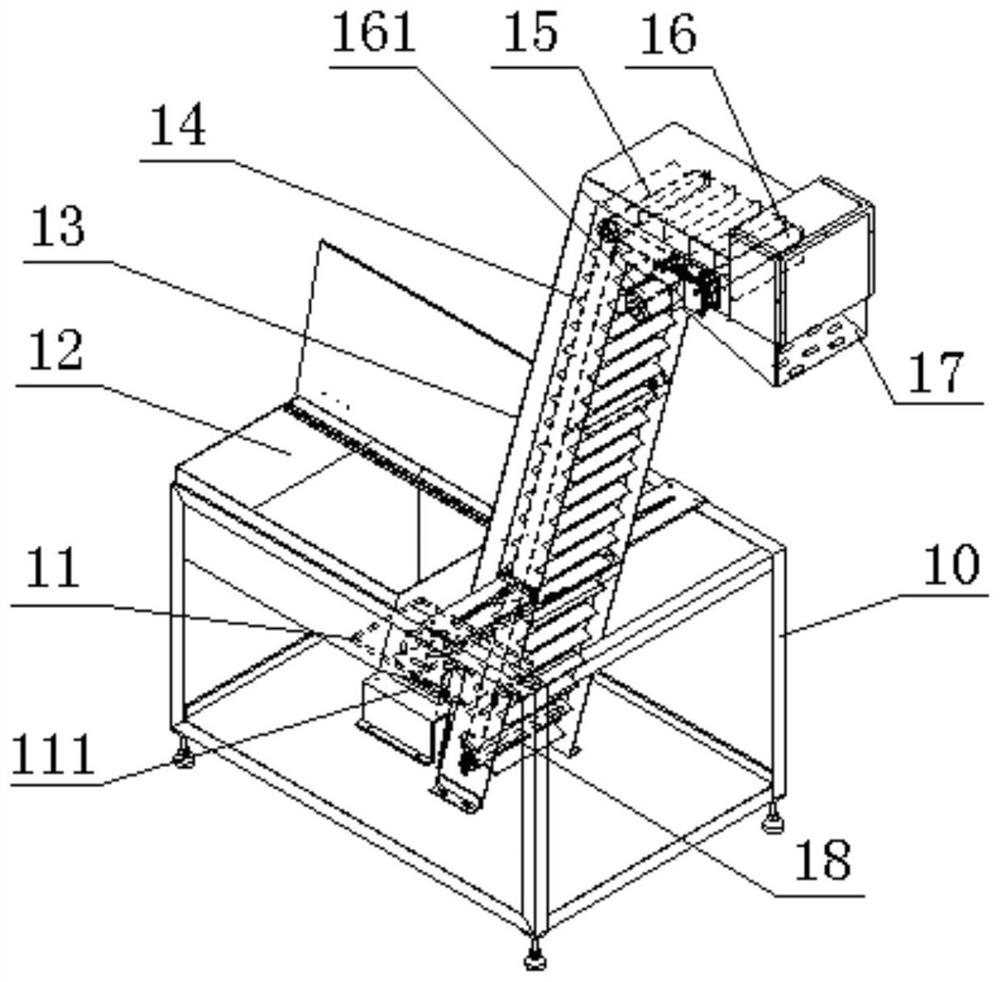

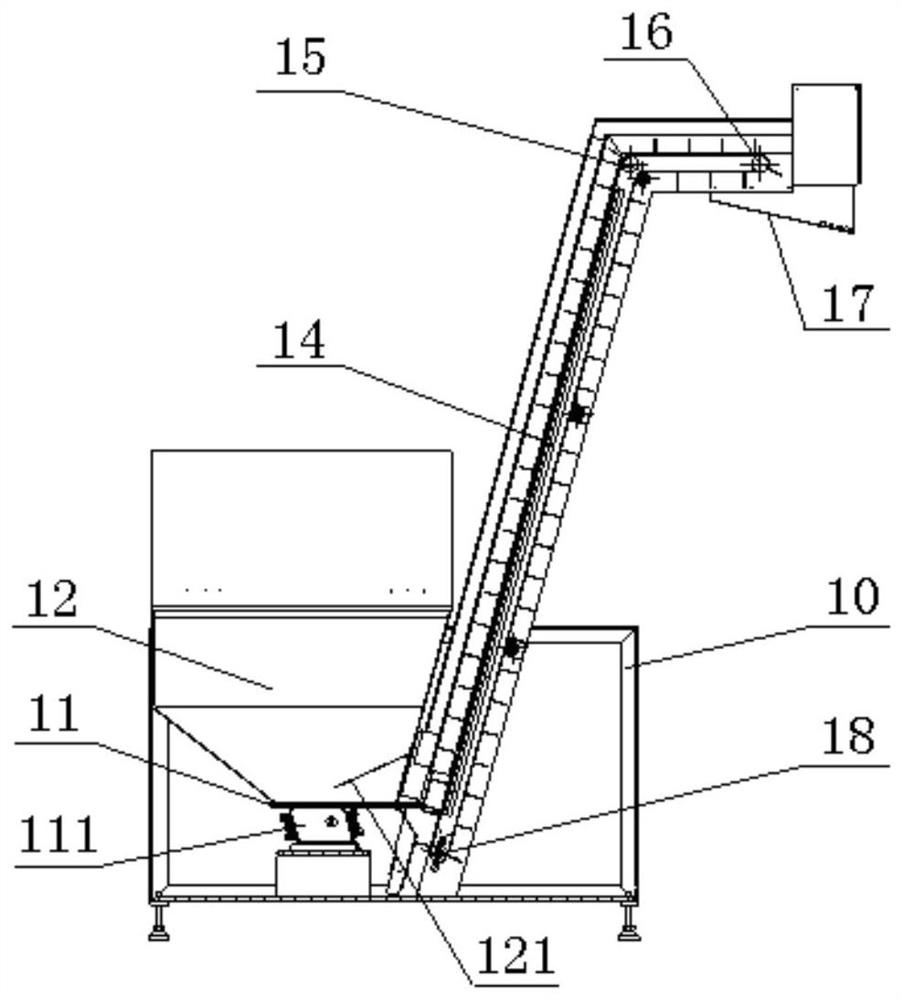

[0039] Described hoist 1 comprises frame 13, is located on frame 13 and links to each other with high position motor 161 and is driven by high position driving roll 16, steering roll 15 and low position driven roll 18, places high position drive roll 16, driven roll 18 and The lifting conveyor belt 14 with some bosses on the turning roller 15, the discharge cover 17 connected to the output end of the conveyor belt 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com