Electroplating tank body automatic water inlet and water outlet mechanism and device

A water outlet mechanism and automatic technology, applied in cranes, electrolysis processes, electrolysis components, etc., can solve the problems of low degree of automation, high labor intensity, and high labor costs, and achieve less chemical residues, labor intensity and labor costs, and loading and unloading. Product convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

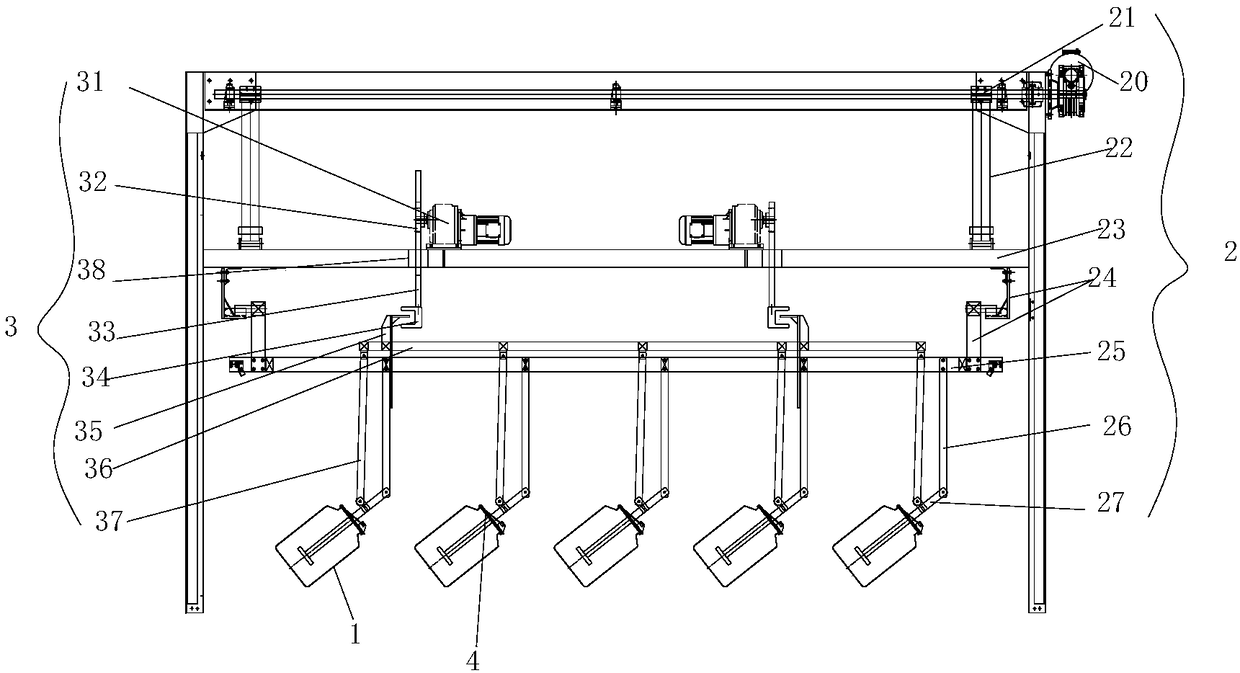

[0033] Such as Figure 1-Figure 3 The specific embodiment of the automatic water inlet and outlet mechanism of the electroplating tank shown in the present invention includes: a lifting assembly 2, a thrust assembly 3 and a clamp 4 for fixing the can-shaped product 1, and the lifting assembly 2 includes: a lifting motor 20, The reel 21 coaxially connected with the output shaft of the lifting motor 20, the lifting sling 22 wound on the reel 21, the fixed main rod 23 fixed at the end of the lifting sling 22, the fixed main rod 23 fixed below the fixed main rod 23 through the lifting bracket 24 Lifting bar 25, a plurality of lifting plates 26 arranged and fixed on the lifting bar 25, and a main conductive rod 27 rotatably connected to the end of the lifting plate 26; Motor 31, the gear 32 that is coaxially connected with the output shaft of thrust motor 31, the rack 33 that meshes with gear 32, the suspension hook 34 that is fixed on the lower end of the rack 33, the fixed frame ...

Embodiment 2

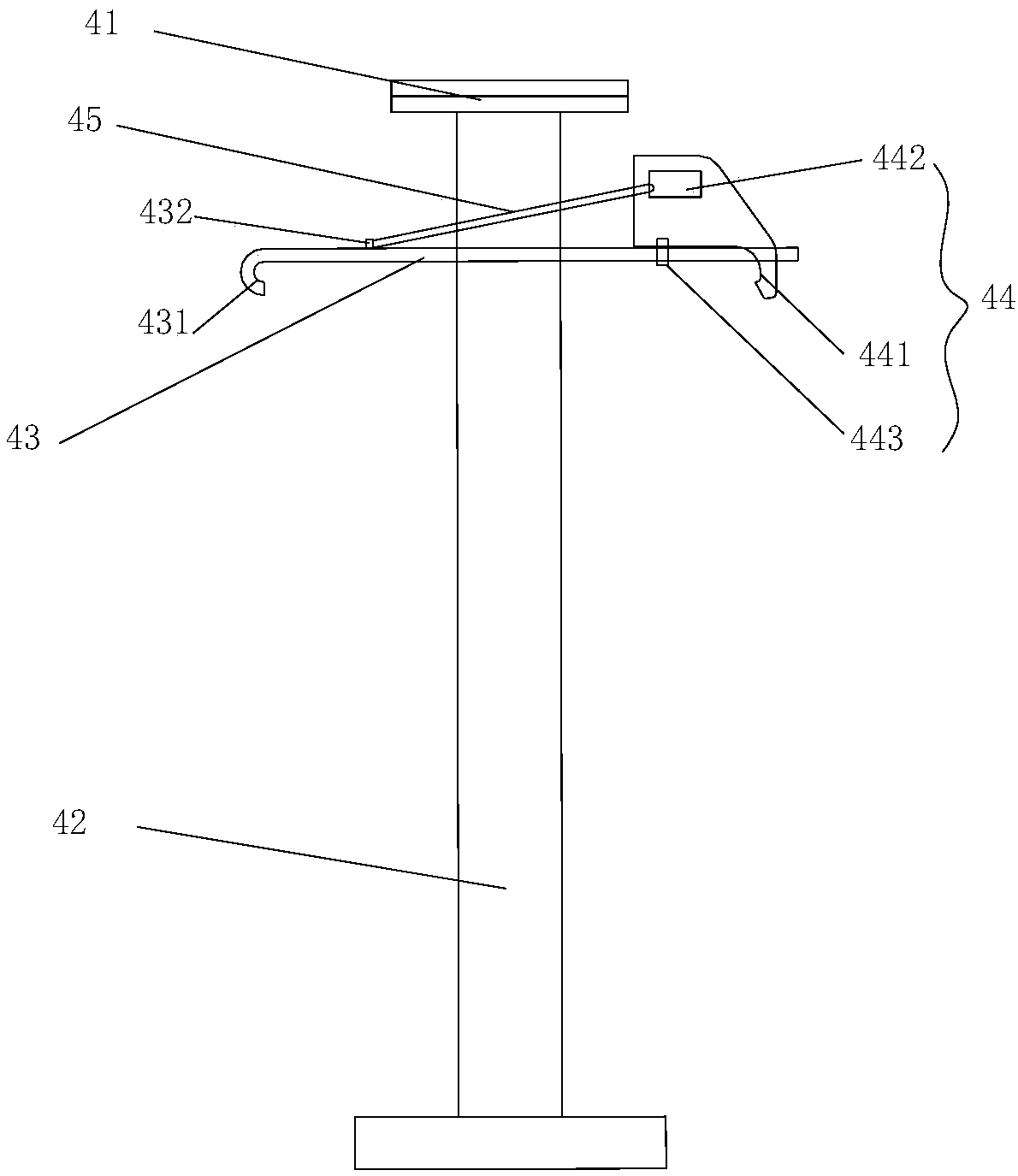

[0039] Such as Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is only that two main conductive rods 27 are hinged on a lifting suspension plate 26 in embodiment 2, and the two main conductive rods 27 can be installed on both sides of the lifting suspension plate 26, The bottom end of the main conductive rod 27 is connected to the product installation cross bar 28, and the clamp installation blocks 41 of the two clamps 4 are respectively installed on the product installation cross bar 28 at the docking position with the main conductive rod 27. The rod 28 is hinged. A plurality of main conductive rods 27 are installed on one lifting suspension plate 26, that is, a plurality of tank-shaped products 1 are installed, and the thrust boom 37 drives two tank-shaped products 1 to rotate by driving the product installation cross bar 28 at the same time, so that multiple tank-shaped products 1 can be realized. Product 1 is electroplated at the same time, greatl...

Embodiment 3

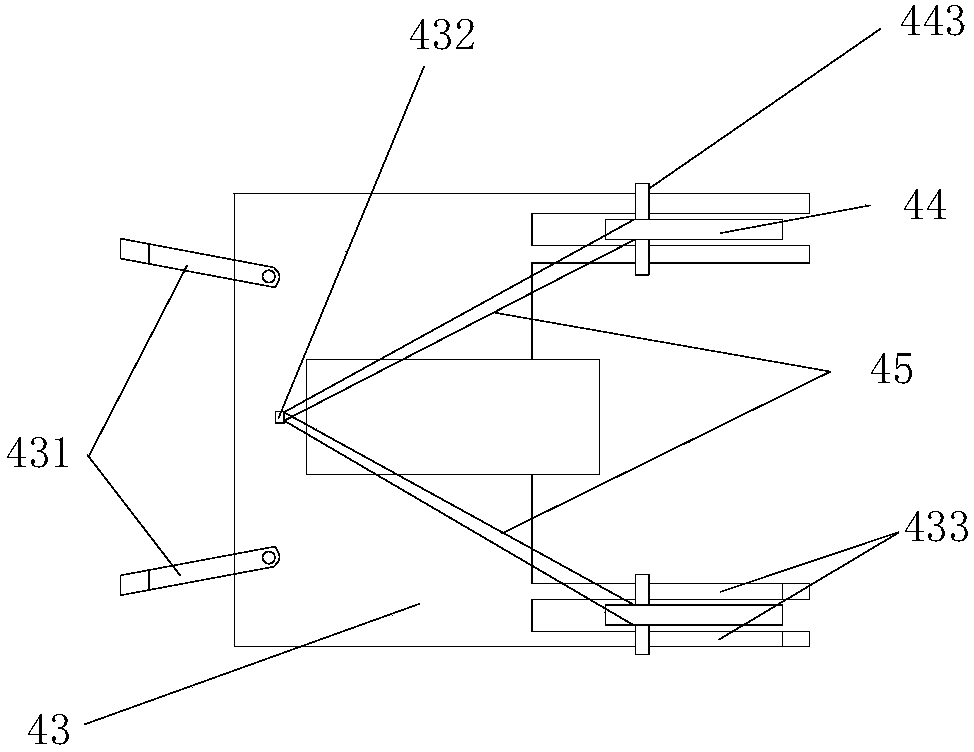

[0041] The clamp 4 structure of embodiment 3 is different from embodiment 1, see Figure 5 and Figure 6 , the first hook 431 and the conductive titanium plate 43 have an integrated structure, and the end of the conductive titanium plate 43 away from the first hook 431 has a long hole 434; the bottom of the fixed hook 44 has a sliding block 444, and the sliding block 444 has a sliding part 4441 and an anti-off part 4442, the length of the sliding part 4441 is less than the length of the elongated hole 434; the length of the anti-off part 4442 is adapted to the length of the elongated hole 434, just can pass through the elongated hole 434, and there is a rubber band fixing ring on the conductive titanium plate 43 432. This ensures that the anti-off part 4442 can pass through the elongated hole 434, and is not easy to fall off. Since there is a gap between the sliding part 4441 and the elongated hole 434, the fixed hook 44 can move in the elongated hole 434, and can be tightene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com